What is Polycarbonate Plastic?

Polycarbonate (PC) is a durable, transparent thermoplastic known for its exceptional impact resistance, optical clarity, and thermal stability. These properties make it a popular choice in various industries, including automotive, electronics, construction, medical devices, and food packaging.

Read more: Plastics Bonding – What is the most effective adhesive?

Characteristics of Polycarbonate Plastic

- High Impact Resistance: Polycarbonate can withstand significant force without cracking or breaking, making it ideal for protective applications.

- Optical Clarity: Its transparency allows for high light transmission, making it suitable for applications requiring clear materials.

- Thermal Stability: Polycarbonate maintains its properties over a wide temperature range, making it suitable for both hot and cold environments.

- Lightweight: Despite its strength, polycarbonate is lightweight, facilitating easier handling and installation.

Applications of Polycarbonate in Various Industries

Thanks to its superior properties, polycarbonate is widely used in multiple industries:

Automotive

Used in headlamp lenses, interior components, and glazing due to its lightweight, durability, and heat resistance. Enhances aerodynamics and fuel efficiency without compromising strength.

Electronics & Home Appliances

Polycarbonate and its blends are widely used in electronic and household appliances like refrigerators, air conditioners, coffee machines, food processors, flosser and steam iron water tanks.

- It allows free-form shaping, improving design flexibility and durability.

- Its excellent electrical insulation properties make it ideal for battery casings, switch covers, and protective enclosures.

Prostech specializes in adhesive solutions for the Electronics and Home Appliance industries. Contact us for expert consultation on your adhesive needs.

Electrical

Common in circuit breakers, switch covers, plugs, and connectors due to its impact resistance and insulation properties.

Construction

A glass alternative for roofing, facades, skylights, and security windows, thanks to its UV resistance, durability, and transparency.

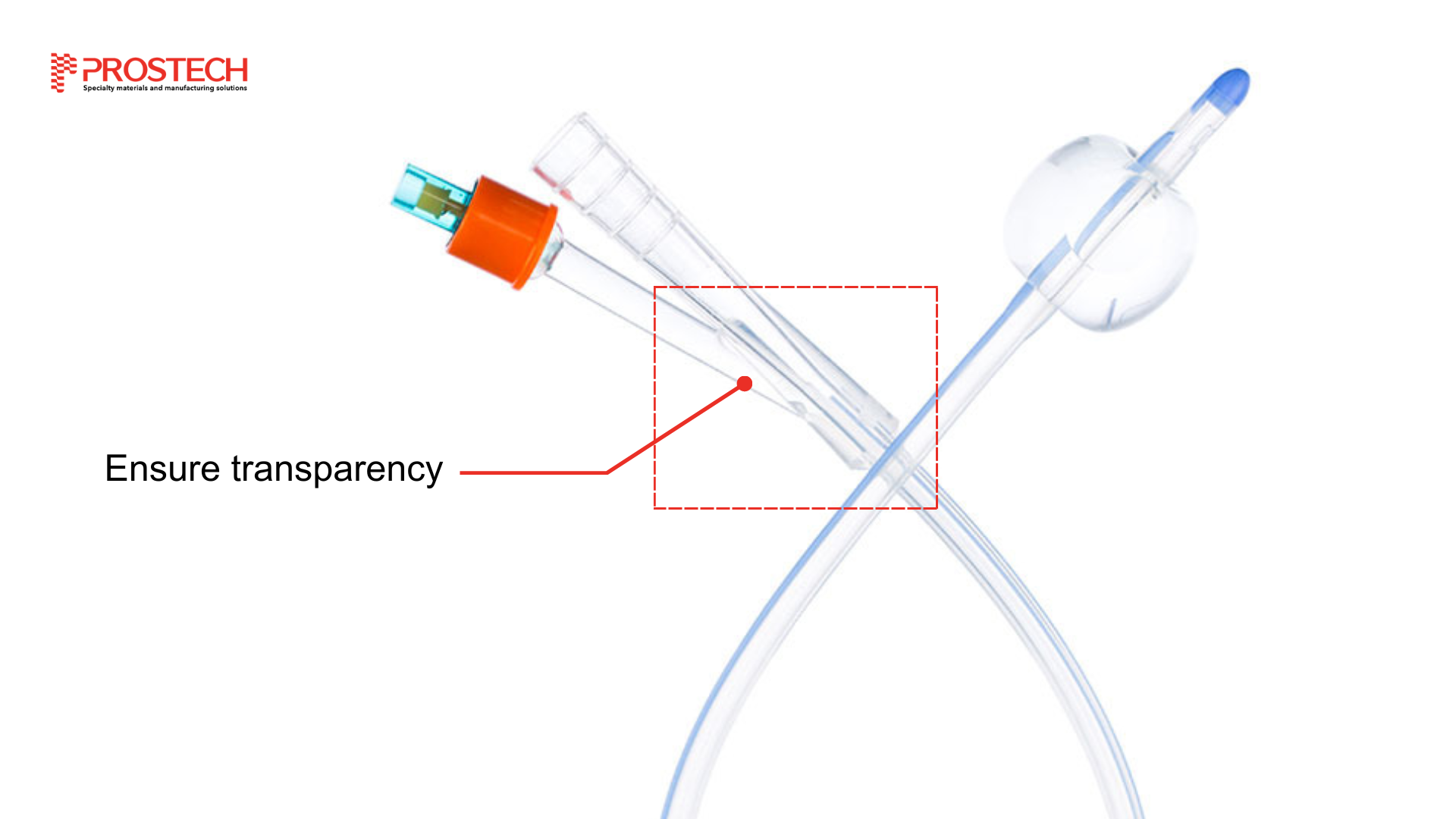

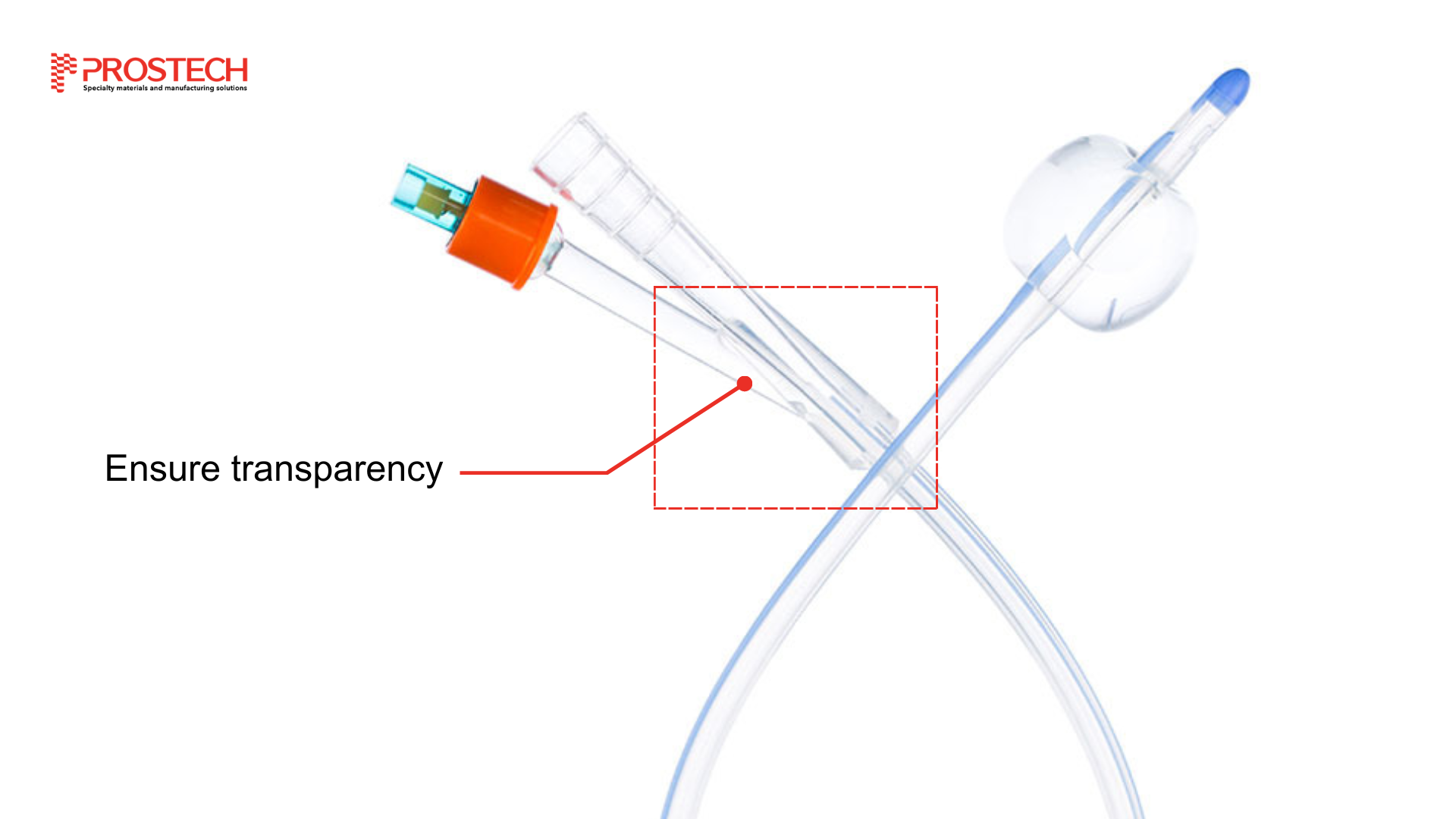

Medical Devices

Medical-grade polycarbonate is widely used due to its clarity, heat resistance, dimensional stability, and toughness.

- It can be sterilized using ethylene oxide, high-energy radiation, and autoclaving cycles.

- Common applications include surgical instruments, medical consumables, drug delivery systems, blood filters, and blood tanks.

Polycarbonate bonding in medical device manufacturing requires adhesives that meet strict industry regulations. Read more about Prostech’s medical-grade adhesive solutions here:

Guideline to disposable medical devices adhesives

7 Reasons why Light-Curable Adhesives are Ideal for Medical Device Assembly

Food Packaging

Preferred for reusable food containers, baby bottles, and beverage storage due to its heat resistance and safety for food contact.

Prostech is a leading provider of adhesive solutions for industrial applications, authorized distributor of top brands like Bostik, Permabond, ITW Performance Polymers, and Momentive for polycarbonate bonding. With years of experience in the adhesive industry, we understand the unique surface properties, environmental conditions, and material requirements for each bond. Let us help you select the most suitable product for your needs.

Contact us now for expert advice and customized solutions!

Why is Bonding Polycarbonate Challenging?

Bonding polycarbonate can be difficult due to several factors:

Chemical Sensitivity

Polycarbonate is susceptible to solvents, which can cause stress cracking or crazing, compromising its structural integrity. Be cautious when selecting cleaners, surface treatments, and adhesives. Avoid solvents such as benzene, acetone, gasoline, and carbon tetrachloride, as they may damage the bonding surface.

Thermal Expansion

Polycarbonate has a high coefficient of thermal expansion, which can create stress at the bond line under temperature fluctuations.

Surface Energy

While polycarbonate has a relatively high surface energy, proper surface preparation is still necessary to ensure optimal adhesion.

Stress cracking prevention: Over-insertion of tubes into cylindrical joints due to adhesive lubrication can lead to stress. Using stops or automated assembly can minimize this risk.

Prostech has extensive experience in industrial adhesive solutions. Contact us for expert advice on selecting the right adhesive for your polycarbonate application.

The Best Adhesives for Polycarbonate Bonding

Choosing the right adhesive for polycarbonate bonding is crucial to ensure durability, flexibility, and resistance to environmental factors. Depending on your application, different adhesives offer unique advantages. Below are some of the best adhesives for bonding polycarbonate, along with their strengths and limitations.

1. UV Adhesives – Fast Curing & High Aesthetics

UV adhesives are an excellent choice for polycarbonate bonding in transparent applications that require a clear, aesthetically pleasing finish. These adhesives cure rapidly under UV light, forming a high-strength and durable bond.

Read more: UV Adhesive – A Comprehensive Overview

Advantages:

- Fast curing time, ideal for high-speed production.

- Provides a clear, invisible bond, perfect for optical applications.

- Resistant to moisture, chemicals, and temperature fluctuations.

Disadvantages:

- Requires UV light exposure for proper curing.

- May not be suitable for opaque materials that block UV penetration.

Read more: Curing Mechanism of UV Adhesive

Recommended UV Adhesives for Polycarbonate Bonding:

- ITW Performance Polymers Tru-Bond UB 6500S: a high-strength UV adhesive offering excellent sealing, water resistance, and durability. Its superior aging performance extends product lifespan, making it ideal for various environments and demanding applications.

- Permabond UV630

Explore Prostech’s UV adhesive solutions here!

2. Cyanoacrylate (Super Glue) for Polycarbonate Bonding

Cyanoacrylate adhesives (commonly known as super glue) are popular for quick and easy polycarbonate bonding. They provide instant adhesion, but they can become brittle over time, which may lead to stress cracking.

Read more: UV-curable cyanoacrylate adhesives (UVCA) for medical devices

Advantages:

- Instant bonding within seconds.

- Requires minimal surface preparation.

- Low-odor and low-bloom grades available for aesthetic applications

Disadvantages:

- Can become brittle and lead to stress cracks over time.

- Not ideal for load-bearing or high-flex applications.

Read more:

Recommended Cyanoacrylate Adhesive for Polycarbonate Bonding:

Find the right cyanoacrylate adhesive for your polycarbonate bonding needs

Cyanoacrylate Adhesive Products

3. Epoxy Adhesives for Polycarbonate Bonding

For structural polycarbonate bonding, epoxy adhesives offer high strength, durability, and chemical resistance. However, choosing the right formulation is essential to prevent stress cracking in polycarbonate.

Read more: Epoxy Resin and Its Industrial Applications – Top Epoxy Products in the Market

Advantages:

- Exceptional bonding strength, suitable for high-stress applications.

- Withstands extreme temperatures and harsh environments.

- Suitable for industrial and manufacturing applications.

Disadvantages:

- Longer curing time compared to other adhesives.

- Some formulations may lead to brittleness or stress cracking in polycarbonate.

Read more: Mixing Two-Component Epoxy Adhesive – Is it difficult?

Prostech understands epoxy adhesives and the complexities of polycarbonate bonding. We consider surface properties, bonding requirements, and environmental conditions to recommend the most suitable epoxy adhesive for your needs. Explore our epoxy adhesive solutions here or contact us now for expert consultation and personalized recommendations!

4. Polyurethane Adhesives for Polycarbonate Bonding

Polyurethane adhesives offer a flexible and impact-resistant bond, making them ideal for applications exposed to vibrations or movement. These adhesives provide a balance of strength and flexibility for polycarbonate bonding.

Read more: The best adhesives for bonding rubber

Advantages:

- Flexible bonding, allowing movement without breaking.

- Good resistance to impact, moisture, and temperature variations.

- Suitable for both indoor and outdoor applications.

Disadvantages

- Longer curing time compared to cyanoacrylate.

- May require clamping to ensure a proper bond.

Polyurethane Adhesive Products

5. Silicone Adhesives for Polycarbonate Bonding

Silicone adhesives are widely used for polycarbonate bonding in construction and sealing applications. They provide excellent weather resistance, but their bond strength is lower than that of epoxies or polyurethanes.

Advantages

- Highly flexible, ideal for sealing and waterproofing.

- Resistant to extreme weather conditions, including UV exposure.

- Bonds to various surfaces, including polycarbonate, glass, and metal.

Disadvantages

- Weaker bond strength compared to epoxy and polyurethane adhesives.

- Not ideal for structural bonding or high-stress applications.

Recommended Silicone Adhesives for Polycarbonate Bonding:

Explore Prostech’s silicone adhesive solutions:

Each adhesive type has its own strengths and limitations. The best adhesive for polycarbonate bonding depends on factors like:

- Application requirements (structural, aesthetic, flexible, or high-strength)

- Environmental exposure (moisture, heat, UV, or chemicals)

- Processing speed (fast curing vs. long-term durability)

- Surface preparation (some adhesives require primers or UV curing)

Need help selecting the right adhesive? Contact Prostech for expert consultation and customized adhesive solutions tailored to your needs.