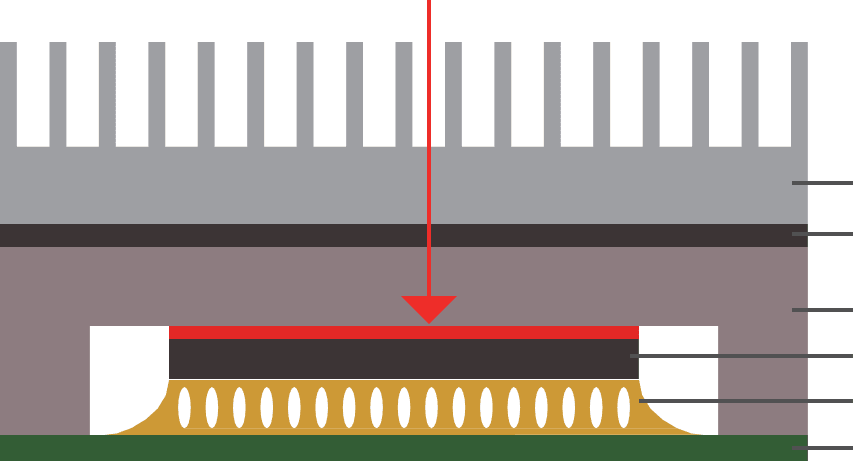

LiPOLY’s TIM14 is a two-part compound silicone base thermal conductive adhesive gel. which is mainly designed to provide efficient thermal transfer for the cooling of chip packaging. The high deformation properties perfectly fill small air gaps to eliminate tolerances. It’s ideally suited for manual dispensing applicator and dispensing robot. Friendly design escape from high cost of cold-chain transportation and freeze preservation.)

FEATURE

- Excellent thermal conductivity 4.0 W/m*K

- No freeze preservation required

- Dispensable for serial manufacture

- Adhesive for IC packaging design

APPLICATION

- Designed to provide efficient thermal transfer for the cooling of chip packaging as TIM-1.

- 5G base station & infrastructure

- EV electric vehicle

|

PROPERTY |

TIM14 |

TEST METHOD |

UNIT |

|

Color |

Gray (A part) White (B part) |

Visual |

– |

|

Resin base |

Silicone |

– |

– |

|

Form |

Grease |

Visual |

– |

|

Viscosity A |

380 |

ISO 3219 |

Pa.s |

|

Viscosity B |

380 |

ISO 3219 |

Pa.s |

|

Density |

3.0 |

ASTM D792 |

g/cm³ |

|

Application temperature |

-50~180 |

– |

°C |

|

Working time |

24 @ RT |

By LiPOLY |

hrs |

|

Cure conditions |

125°C / 90 mins |

By LiPOLY |

– |

|

Volatile content |

< 0.4 |

150°C x 24h |

% |

|

BLT |

27 |

– |

µm |

|

Elongation |

110 |

ASTM D412 |

% |

|

Adhesive strength |

3.5 |

– |

kgf/cm² |

|

ELECTRICAL |

|||

|

Dielectric breakdown |

25 |

ASTM D149 |

KV/mm |

|

Surface resistivity |

>10¹³ |

ASTM D257 |

Ohm |

|

Volume resistivity |

>10¹³ |

ASTM D257 |

Ohm-m |

|

THERMAL |

|||

|

Thermal conductivity |

4.0 |

ASTM D5470 |

W/m*K |