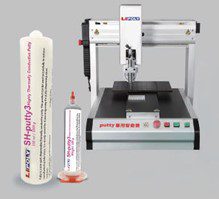

LiPOLY SH-putty3 is a one-part dispensable material with thermal conductivity 8.0 W/m*K. High defor- mation can fill small air gaps perfectly to remove tolerance. It also can overcome overflow and drying problems to increase the thermal conductivity. SH-putty3 is a great alternative to thermal grease and ideally suited for dispensing using the dispensing robot.

FEATURE

- Thermal conductivity:8.0 W/m*K

- Thermal conductivity:8.0 W/m*K

- Bond line thickness:100-3000µm

- Designed to remove manufacturing tolerances

- Does not produce stress on delicate components

- No vertical flow

- Dispensable for serial manufacture

- For any high compression and low stress application

APPLICATION

- Between CPU and heat sink

- Between a component and heat sink

- High speed mass storage drives

- Telecommunication hardware

- Flat-panel displays

- Set-top box

- IP CAM

- 5G base station & infrastructure

- EV electric vehicle

|

PROPERTY |

SH-putty3 |

TEST METHOD |

UNIT |

|

Color |

Gray |

Visual |

– |

|

Resin base |

Silicone |

– |

– |

|

Viscosity |

17000 |

DIN 53018 |

Pa.s |

|

Density |

3.4 |

ASTM D792 |

g/cm³ |

|

Application temperature |

-60~180 |

– |

°C |

|

Bond line thickness |

100~3000 |

– |

μm |

|

Shelf life |

60 months |

– |

– |

|

ROHS & REACH |

Compliant |

– |

– |

|

ELECTRICAL |

|||

|

Dielectric breakdown |

12 |

ASTM D149 |

KV/mm |

|

Volume resistivity |

>10¹³ |

ASTM D257 |

Ohm-m |

|

THERMAL |

|||

|

Thermal conductivity |

8.0 |

ASTM D5470 |

W/m*K |

|

Thermal impedance@10psi |

0.039 |

ASTM D5470 |

°C-in²/ W |

|

Thermal impedance@30psi |

0.035 |

ASTM D5470 |

°C-in²/ W |

|

Thermal impedance@50psi |

0.031 |

ASTM D5470 |

°C-in²/ W |