Lead-free solder wire with the same characteristics as a leaded solder wire? Is this possible? Get to know updated technology and discover an alloy with perfect strength.

An innovation solution

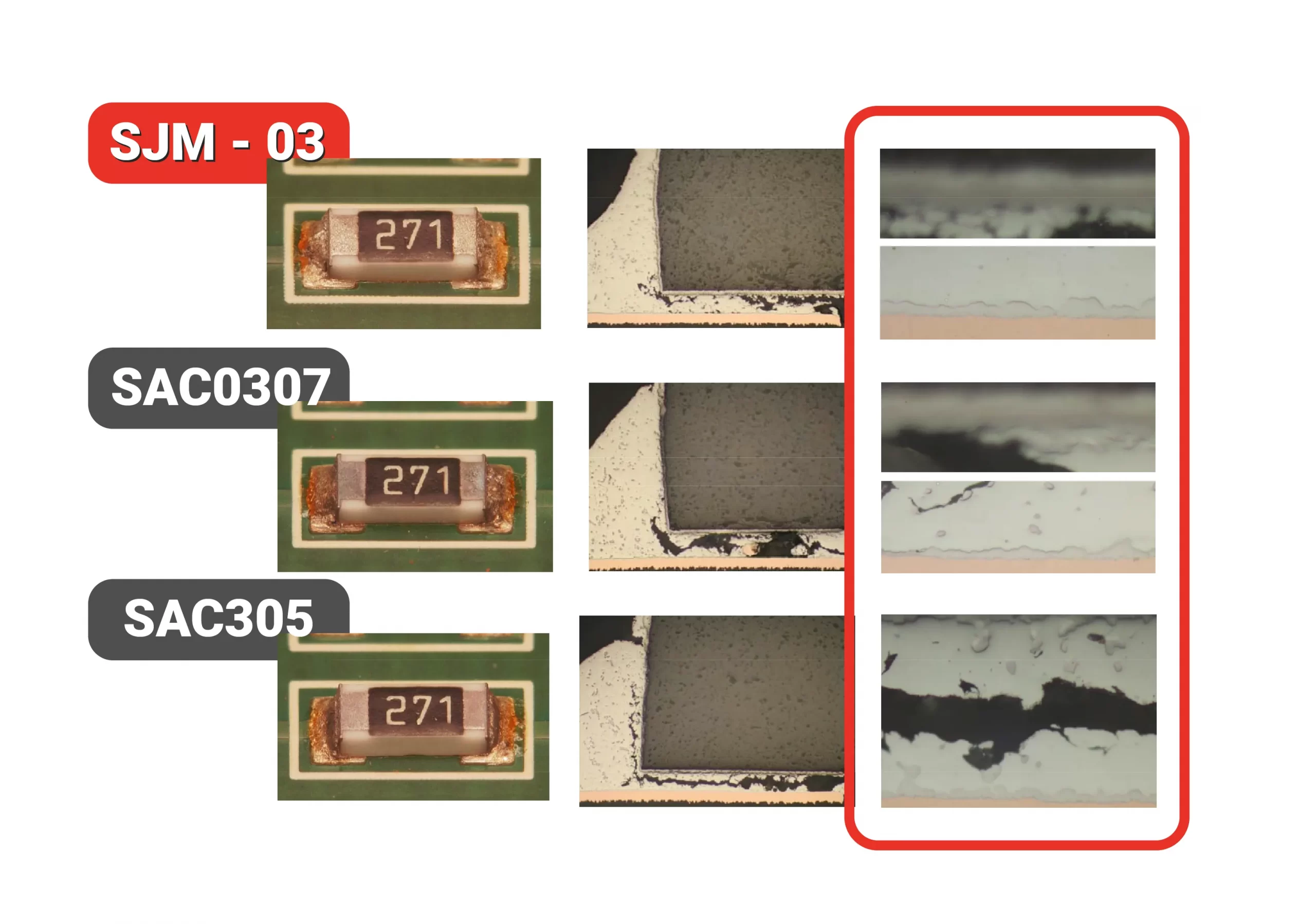

The solder wires and solder pastes of the SJM series are the results of our soldering material partner’s research program’s extensive development work. While the lead-free alloys used until now already show cracks after 500 cycles, the patented SJM-03 for example remains intact even after 1,500 cycles and shows no cracks at all.

With perfect strength – improved 60% comparing to SAC 305

The SJM series offers a new dimension of strength with lead-free alloys. The initial strength of SJM-03 compared to the often used SAC 305 alloy can be improved 60%

Advantages of the SJM series at a glance

- lead-free

- no crack formation

- perfect strength

- between 0.3% to 4% silver content

- patented alloy

- ideal for plated through hole

The alloy metal and its advantages

- Bi (Bismuth): increases tensile and tear strength, strengthens long-term reliability

- FE (iron): minimizes the wear of soldering tips

- Sb (antimony): ensures an even higher long-term reliability

- Ga (Gallium): prevents oxidation

The strength after 2000 cycles can even be increased to up to 35%. The optimum solution is also available for even greater strength:

Lead-free alloys in the SJM series: Silver content of 0.3% to 4%

Ideal for plated through holes

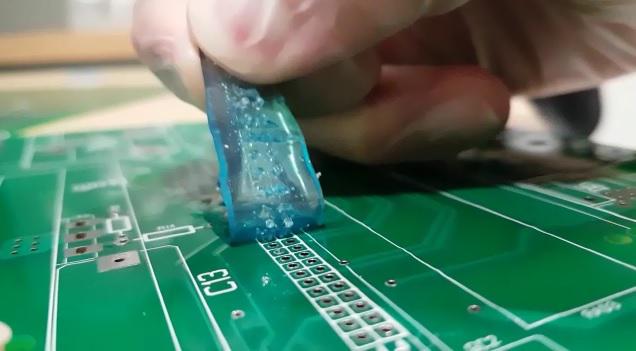

Typical features of all alloys of the SJM series are its superior wetting and processing properties (RMA compliant). As a result, they are ideally suited for soldering on boards with plated through holes.