The Role of Efficient Industrial Battery Chargers in the Battery energy storage systems (BESS)

As the demand for sustainable and resilient energy solutions increases, the need for high-performing battery chargers for lithium-ion batteries becomes critical. Efficient chargers ensure minimal energy loss, quicker charging times, and better energy management, which are crucial for applications ranging from renewable energy integration to backup power systems. Furthermore, advanced chargers incorporate features like thermal management and fault detection to enhance the system’s reliability and safety.

Solutions for Battery Energy Storage System

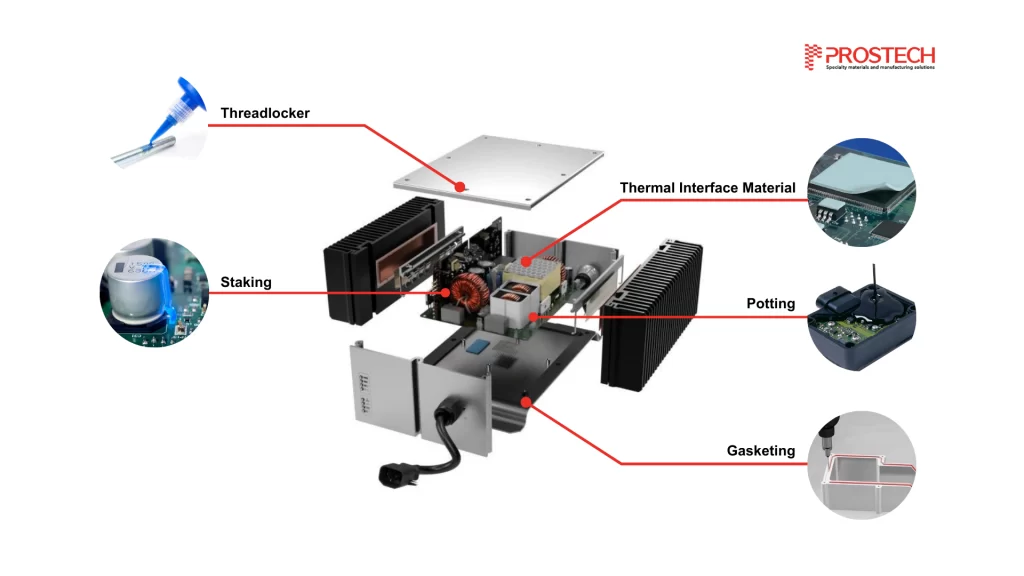

Assembly Challenges in battery charger for lithium-ion battery

The assembly of industrial battery chargers presents several challenges, including effective thermal management to dissipate heat generated during operation, providing environmental protection from moisture, dust, vibrations and maintaining mechanical stability of components under mechanical stresses. These challenges necessitate the use of advanced materials for thermal management, protection, and bonding to enhance the performance, safety, and durability of the chargers.

Prostech’s Innovative Material Solutions for lithium-ion battery chargers

With years of experience in developing advanced materials, Prostech offers a comprehensive range of adhesive solutions designed to address the assembly challenges of industrial battery chargers. These solutions include:

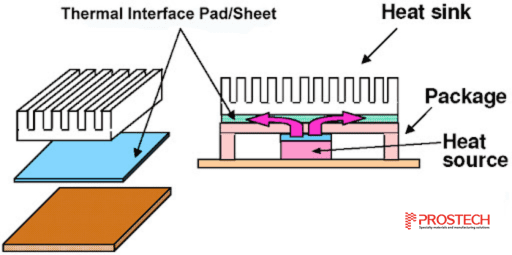

Thermal Interface Material (TIM) for lithium-ion battery chargers

Thermal Interface Material (TIM) is used for thermal management. As these chargers operate, they generate heat, which can adversely affect performance and lifespan if not properly managed. TIM facilitates the transfer of heat away from heat-generating components, such as power electronics and battery cells, to heat sinks or enclosures, where it can be dissipated effectively. By filling gaps and imperfections between mating surfaces, TIM minimizes thermal resistance, optimizing heat transfer and helping to maintain lower operating temperatures.

Potting for lithium-ion battery chargers

Prostech’s potting compounds are used to encapsulate electronic components within the charger, providing robust protection against environmental factors such as moisture, dust, and mechanical shocks.

Gasketing for lithium-ion battery chargers

Gasketing materials from Prostech ensure a secure seal around the charger’s enclosure, protecting internal components from environmental hazards. These materials offer excellent compression set resistance, maintaining their sealing performance over time and under varying conditions.

Staking Adhesive for lithium-ion battery chargers

Staking adhesives secure components in place, providing mechanical stability against vibrations and shocks encountered during operation. They offer strong adhesion to various substrates and help maintain the integrity of the assembly under harsh conditions.

Threadlocker for lithium-ion battery chargers

As these chargers operate, they may be subjected to mechanical vibrations and shocks, which can loosen fasteners over time, leading to potential failures or malfunctions. Threadlocker adhesive is applied to fasteners during assembly, creating a secure and durable bond that prevents them from loosening due to vibrations or thermal cycling.

By leveraging these innovative material solutions, manufacturers can address the complex assembly challenges of industrial battery chargers, ensuring they deliver high performance, safety, and durability. Prostech’s commitment to quality and innovation supports the growing needs of the energy storage industry, providing reliable solutions for efficient and resilient battery energy storage systems (BESS). For more information and to discover how our solutions can benefit your specific applications, contact us for a free consultation and let our experts help you achieve optimal results.