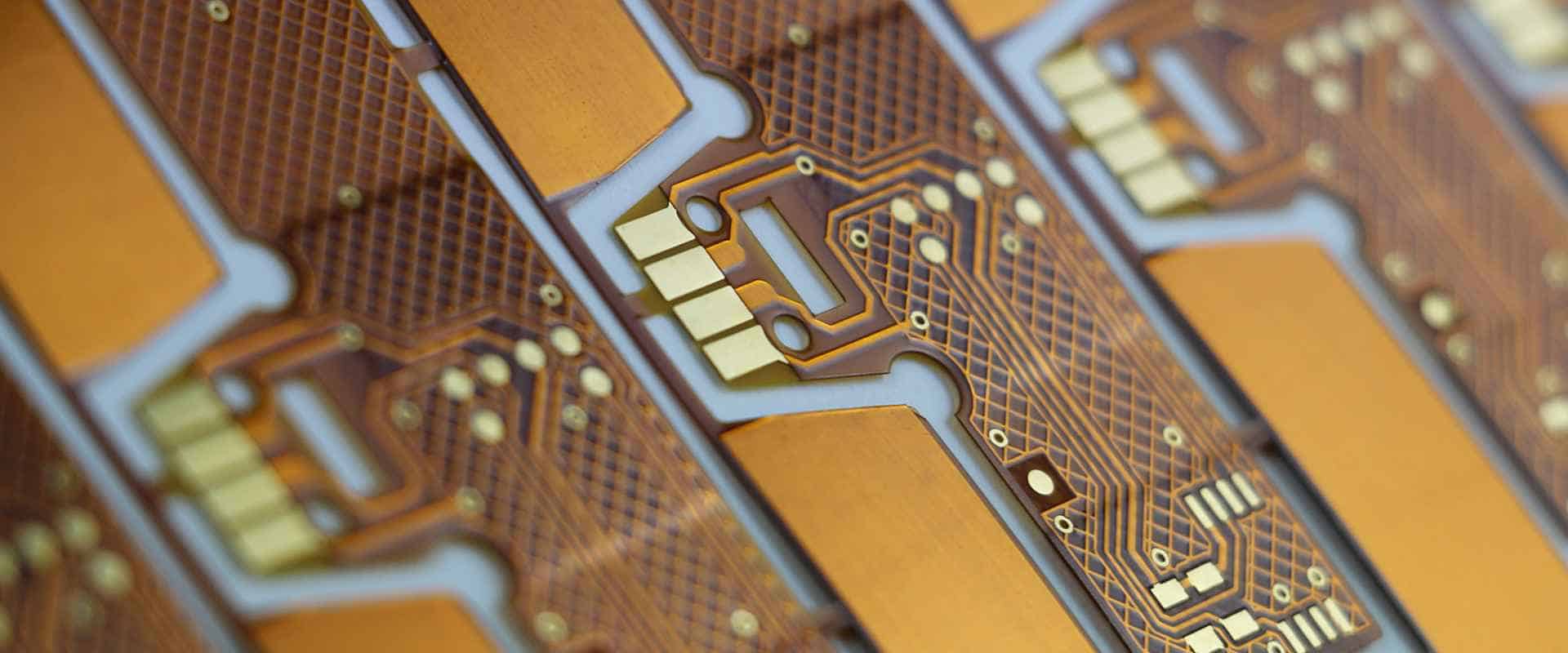

FBC reinforcement is one of the most important applications to ensure the long life of camera modules. Materials for this application need to be considered based on the actual needs and standards of the circuit boards.

FBC is easy to bend with very thin, small, and flexible characteristics for many applications in the electronics industry. Its weaknesses lie in its mechanical, prone to breaking so we need the structural board to enhance its mechanical strength

So FBC reinforcement is usually for the mechanical purpose

Types of FBC reinforcement

There are 3 main types of reinforcement board: PI, FR-4, Stainless Steel

Polyimide

The first one is Polyimide: abbreviated as PI. This is the most popular and promising material because it is the lead in the microelectronics field.

PI is mainly used in the area of the back of the FPC gold finger.

3 main benefits:

- thicken the area to the corresponding connector’s insertion height, making it tightening

- self-lubricating, not high in hardness, which greatly reduces the friction damage to the plugging area;

- low thermal expansion coefficient and high dimensional stability that make FPC reinforcement precision higher.

The thickness of the PI reinforcement sheet is mainly 0.1mm, 0.125mm, 0.15mm, 0175mm, 0.2mm, 0.225mm, 0.25mm.

Recommended Adhesive: H. B. Fuller 6033, Everwide GM596-2, Everwide FP801

FR-4 (Glass Fiberboard)

Fr4 stands out by Its mechanical properties, dimensional stability, impact resistance, and moisture resistance which are higher than paper substrates. This material has excellent electrical performance, and a higher operating temperature and its performance is less affected by the environment.

When it comes to the widespread usage of Fr4, it is on double-sided PCBs, which manufacturers mainly use as the back of the FPC welding area to strengthen the hardness of the welding area and protect the electronics after the patch.

Key features of the FR4

- Wide range of operating temperatures (50°C to 115°C)

- Higher Tg value (about 180°C)

- Offers decent mechanical properties to maintain board structure integrity

- Cost friendly when compared to other materials

Available thickness including 0.15mm, 0.20mm, 0.225mm, 0.25mm, 0.275mm, 0.30mm, 0.4mm, 0.5mm, 0.8mm, 1mm, etc.,

Recommended Adhesive: H. B. Fuller EA6209, Everwide GN827-16, Everwide GN827-17, Everwide GM596-2

Stainless Steel Sheet

Or 303 steel. It is used on occasions requiring free cutting & high surface finish. When requiring high stability, this type of steel is often used.

Common cutting ways like drilling with CNC or cutting with FPC laser can not work with this material it is mainly made by potion etching

General thickness range: 0.1mm, 0.15mm, 0.2mm.

Recommended Adhesive: H. B. Fuller EA6209, Everwide FP321, Everwide FK800, Everwide FP5202, Everwide FP984

Moreover, we have TPX anti-adhesive film, EIM electromagnetic film, etc,.. can be used as reinforcement materials for your application.

The general point to rely on while choosing the material for FBC reinforcement includes reliability/ space and cost-saving/ flexibility/ local harness.

Find it hard to choose, whether is material or adhesive, contact us directly through: