Based on the form of the solder material, it can be divided into the following main types that are widely used:

1. Solder Wire

Solder wire is commonly used in wave solder assembly and electronic circuit repair using soldering irons and soldering stations.

| Leaded Solder Wire | Lead-Free Solder Wire |

Contains lead, a low-melting-point metal that is easy to use. Product codes typically indicate the composition of the solder wire:

| Does not contain lead, making it safer for the environment and human health. It is typically more expensive and used in imported electronic devices for markets with strict regulations, such as Europe and North America. Product codes for lead-free solder wire also indicate the composition: |

| Flux-Core Solder Wire | Halogen-Free Solder Wire |

Contains a flux core that improves solder adhesion and removes impurities from the soldering surface.

| Does not contain halogens, making it environmentally friendly. It is designed for markets that restrict halogen use. |

Factors to Consider When Choosing Solder Wire:

In addition to the alloy composition, other factors to consider when choosing solder wire include:

- Melting temperature

- Type of flux core

- Solder wire diameter

Please contact Prostech for consultancy or refer our Solder Material here:

2.Solder Bar

Solder bar is a type of solder material in the form of a bar, used in the wave solder assembly process. During this process, the solder bar is melted into a liquid form and then applied to the next stages to assemble electronic components onto the circuit board.

Nowadays, most solder bar products are manufactured to eliminate lead, making the wave soldering process less toxic and more environmentally friendly.

One of the most popular solder bar products today is SAC305 solder bar/cored solder wire – lead-free (Pb-free) and with an ideal alloy ratio: 3% Ag, 0.5% Cu and the rest is tin (Sn). Refer to some other solder bar lines:

| Product Number | Alloy Composition | Notable Properties | Melting Temperature (°C) | Specific Gravity |

| PF606 | Sn/3.0Ag/0.5Cu/X | High purity | 217~219 | 7.4 |

| PF610 | Sn/3.0Ag/0.5Cu/0.06Ni/0.01Ge | Belongs to the popular SAC305 solder bar line | 217~219 | 7.4 |

| PF634 | Sn/1.0Ag/0.5Cu/0.04Ni/0.01Ge | Low Ag content | 217~226 | 7.4 |

| PF645 | Sn/0.3Ag/0.7Cu/0.04Ni/0.01Ge | Low Ag content, high purity | 217~226 | 7.3 |

| PF604 | Sn/0.7Cu | High purity | 227~228 | 7.3 |

Please contact Prostech for consultancy or refer our Solder Bar here:

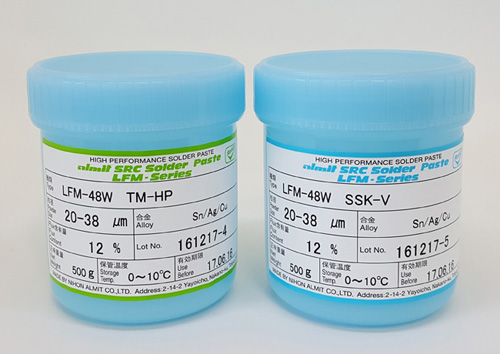

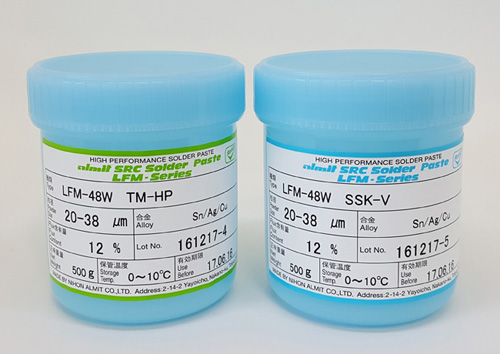

3. Solder Paste

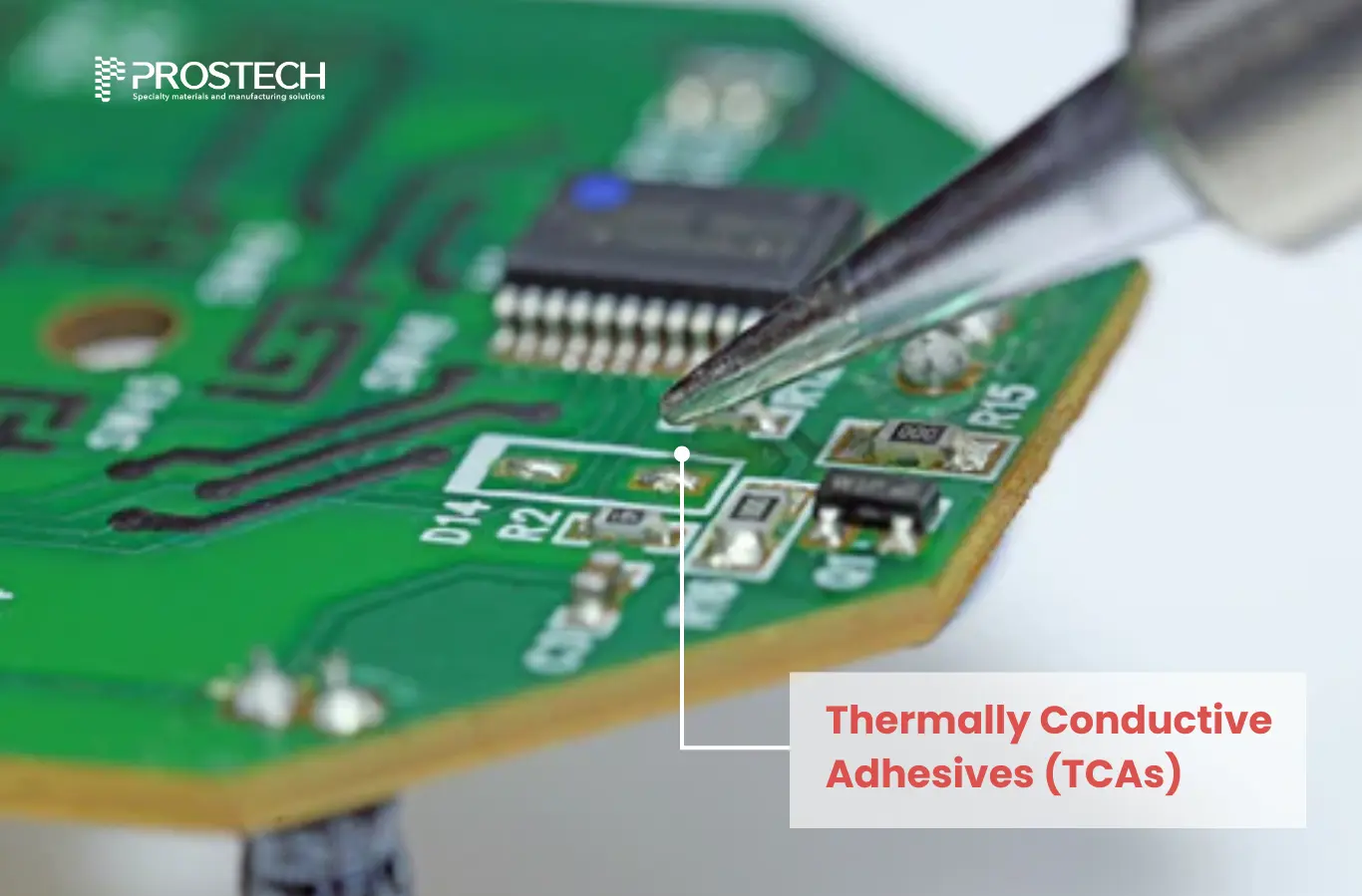

Solder paste is a type of solder material widely used in the Surface Mounted Technology Process (SMT) – the most popular and advantageous printed circuit board assembly process today. Solder paste can also be used in conjunction with automated solder paste dispensing robots in other PCB assembly lines.

Some commonly used solder pastes include:

| Lead-based solder pastes | Lead-free solder pastes |

Formosa SH-6209RMA: 62% Sn – 36% Pb – 2% Ag | Formosa PF606-P26: Sn/Ag3.0/Cu0.5/X |

| Solder pastes for use with automated dispensing robots | Low-temperature solder pastes |

LFM-48U MDA-5 (10-28µm) cho hệ thống Jetting LFM-89 NH-MDL hệ thống tra keo kết hợp Laser Sn62 SRC HM1 RMA (9.5%) | Kem hàn nhiệt độ thấp PQ10 138℃ Kem hàn nhiệt độ thấp PF735 138℃ – chịu được chu kỳ nhiệt độ cao |

In addition to the variety of application methods, solder paste is also divided into many different forms, each used for specific cases, such as:

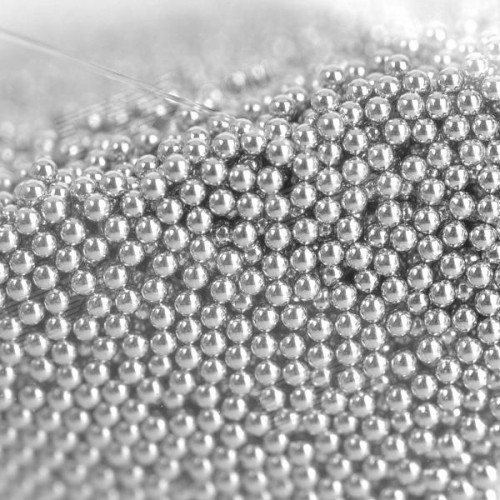

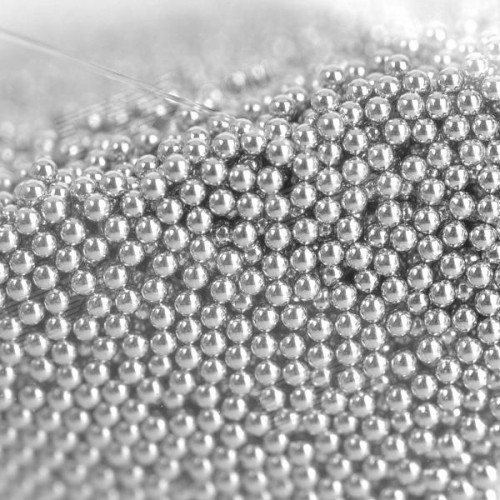

4. Solder Ball (BGA Sphere)

BGA solder spheres are a type of material made from high-purity metals used to create alloys in solder materials. These solder spheres are commonly used in semiconductor packaging applications: PBGA, CBGA, TBGA, CSP, and Flip Chip. The choice of solder spheres depends greatly on the diameter size and the alloy they are made of.

| Product Code | Diameter | Tolerance |

| BS76-50 | 0.76mm~0.50mm | ±20um |

| BS45-10 | 0.45mm~0.10mm | ±10um |

5. Solder Flux

Solder flux is a material used to enhance the adhesion of solder material (solder paste, solder wire, solder bar) to the surface of the printed circuit board (PCB). The diversity of applications and requirements in PCB assembly and semiconductor packaging has driven the development of flux technology, resulting in a variety of fluxes suitable for different applications:

No-clean Flux (NC): is a type of solder flux that leaves no residue on the PCB surface. It is suitable for high-volume production lines, simple PCBs, and reduces the cost of using solder flux cleaners. | Halogen-free Flux: is a type of solder flux that does not contain halogens, a group of volatile chemicals that are not environmentally friendly and can cause corrosion on PCBs. |

|

|

Water Soluble Flux: is a safe and environmentally friendly solder flux used in electronic applications due to its easy cleaning after soldering. | Water Soluble Flux: is a safe and environmentally friendly solder flux used in electronic applications due to its easy cleaning after soldering. |

6. Flux Remover

PCB Cleaner (Printed Circuit Board Cleaner): A type of chemical used to remove solder flux residues left on the surface of a PCB after the PCB assembly process or for PCB repair. Typically, these solder flux residues are difficult to remove and require the use of a specialized chemical that does not affect the performance of the electronic components on the board.

| Environmentally friendly solder flux cleaner | Non-corrosive plastic solder flux cleaner |

| Flux-Off No Clean EXTRAFlux-Off Rosin | Flux-Off AqueousFlux-Off Water Soluble |

| UL94 flame retardant certified solder flux cleaner | Lead-free solder material cleaner |

| Flux-Off Tri-VFlux-Off VZ | Flux-Off Heavy Duty |