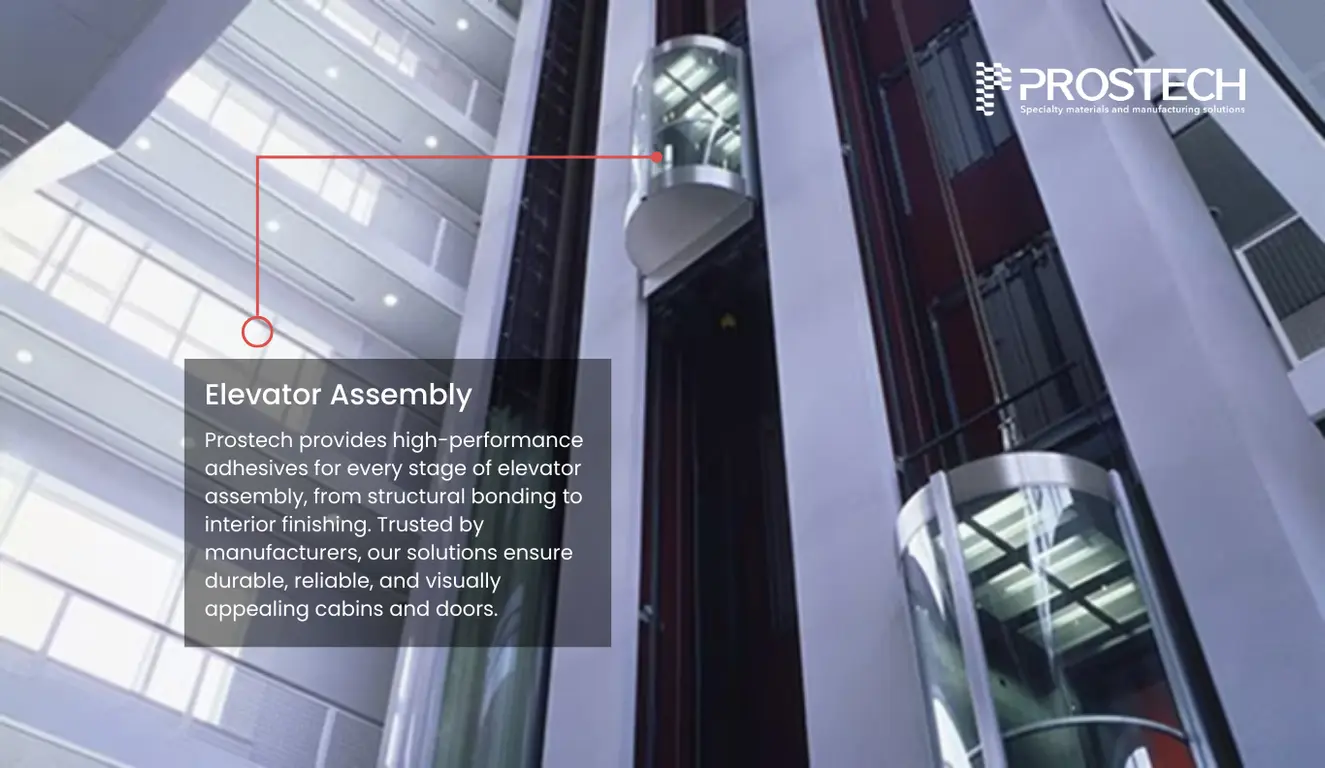

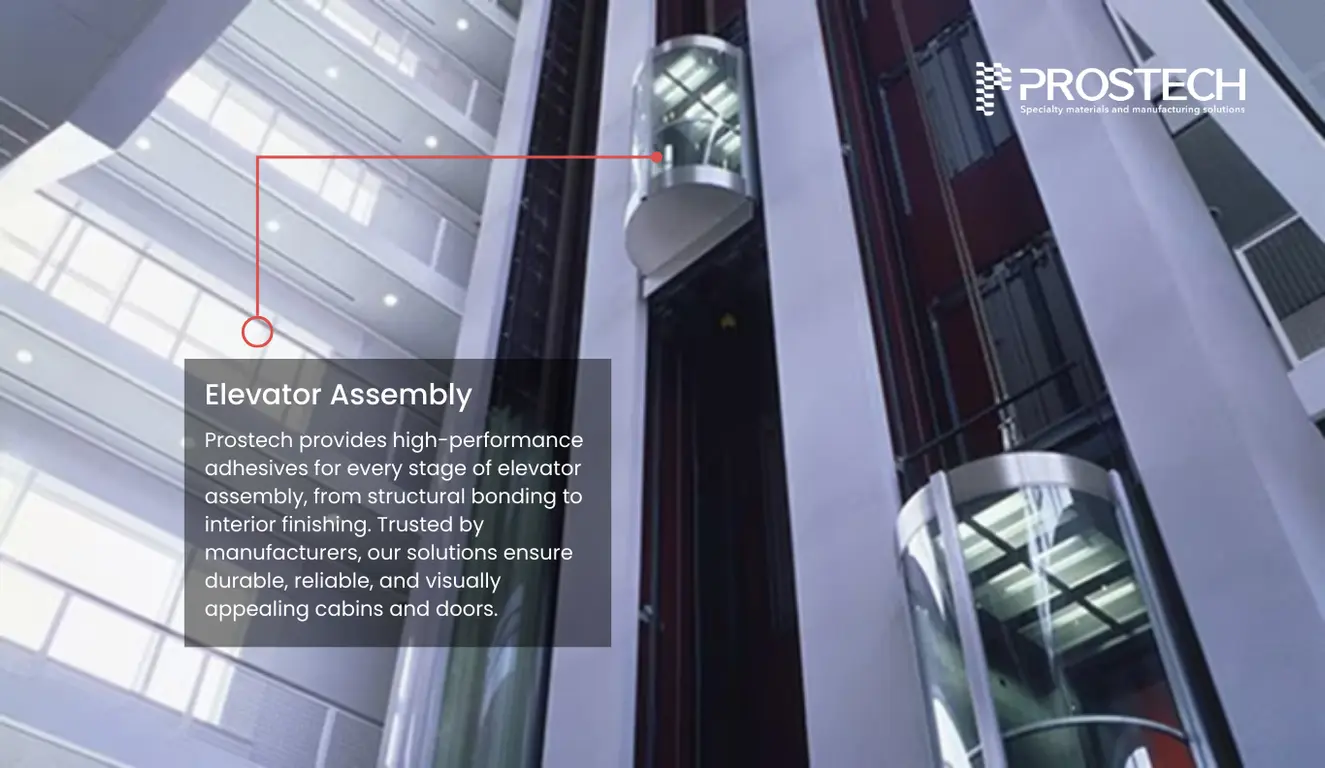

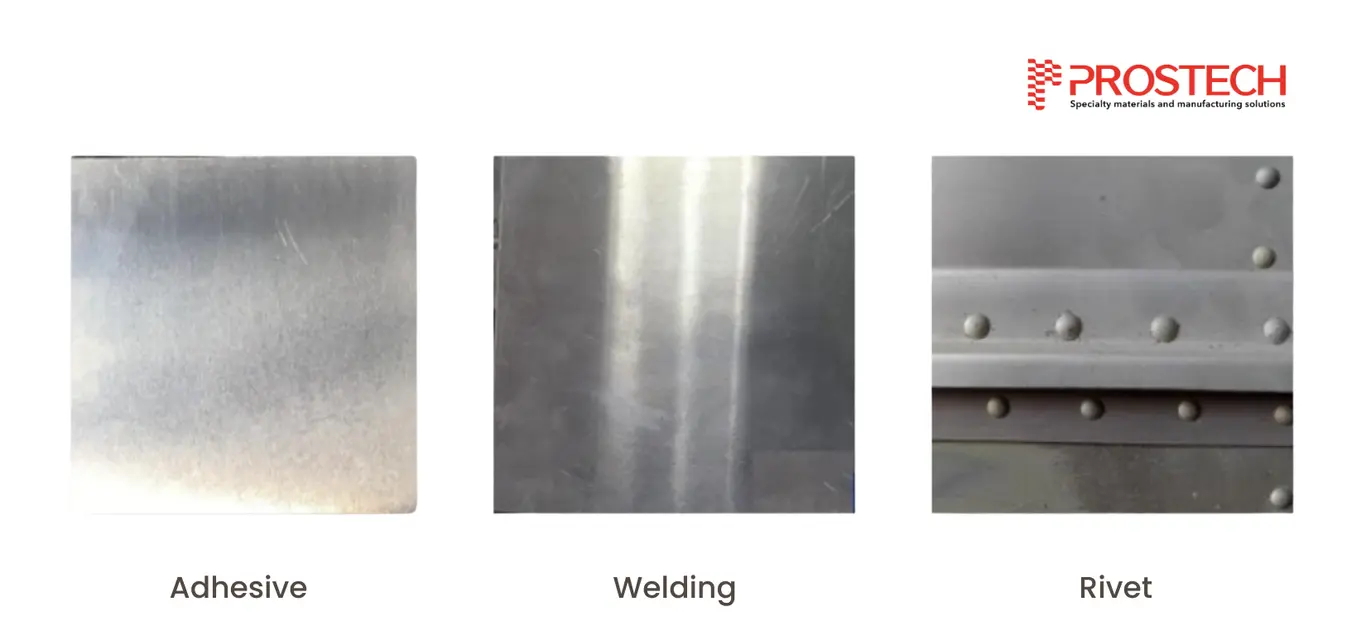

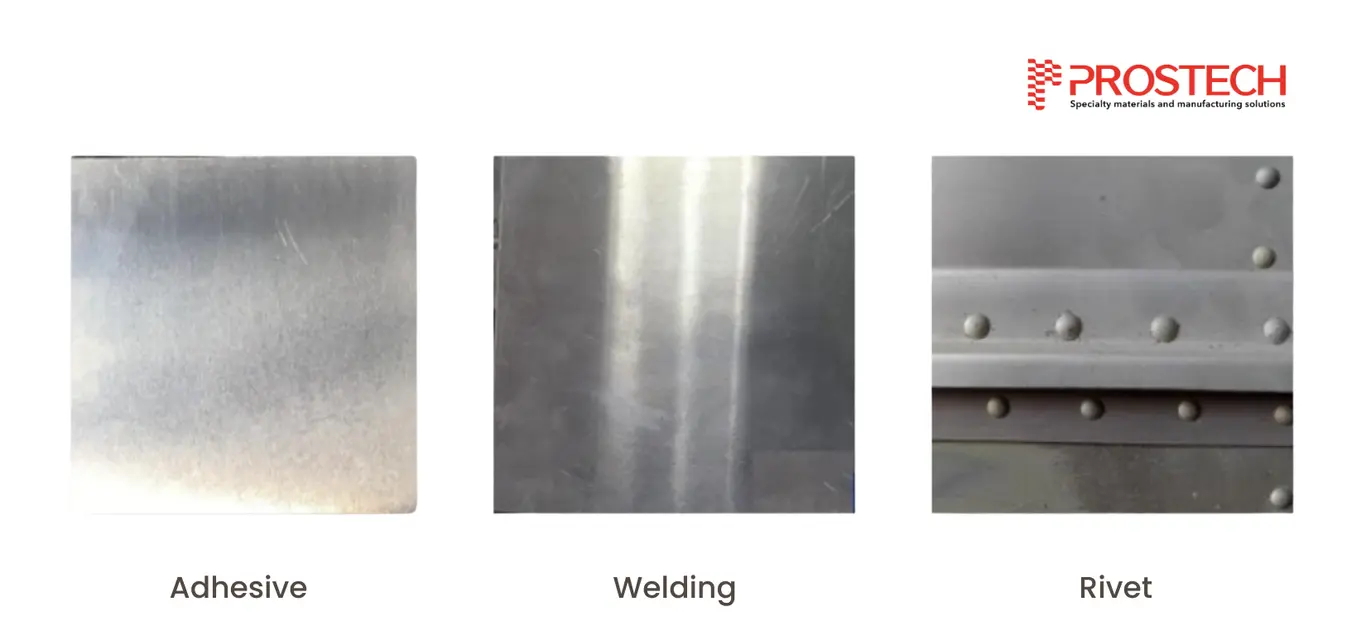

In elevator assembly, traditional fastening methods like welding, rivets, and screws often fall short—causing material stress, increasing assembly time, and requiring additional maintenance. Advanced bonding solutions, including high-performance adhesives and tapes, offer a streamlined alternative—enhancing structural integrity, vibration resistance, and overall safety. However, selecting the right solution can be challenging. At Prostech, we offer a wide range of adhesives designed for every stage of elevator assembly, meeting the industry’s standards.

Why use adhesive & tapes instead of mechanical fastening?

Adhesives have been widely adopted in industries like aerospace and automotive, proving their ability to replace traditional fasteners while improving durability. Here are reasons why tapes are superior to mechanical fastening in those industries—and in elevator assembly as well:

- Sealing and Surface Adaptation – Tapes and adhesives effectively seal gaps and compensate for uneven surfaces, unlike fasteners that may leave spaces and require additional sealing.

- Even Stress Distribution – Mechanical fasteners create stress concentration points, increasing the risk of material failure. In contrast, Tapes and adhesives distribute stress across the bonded area, reducing breakage.

- Noise Reduction – Tapes and adhesives significantly dampen operational vibrations, enhancing passenger comfort. They eliminate the need for additional damping pads, whereas screws and rivets can amplify noise due to metal-to-metal contact.

- Shock Absorption – Tapes and adhesives provide cushioning, reducing strain on the structure and enhancing long-term durability.

- Corrosion Resistance – Unlike metal fasteners, which can rust and weaken over time, adhesives and tapes help prevent corrosion, extending the lifespan of elevator components.

- Simplified Application – Tapes and adhesives allow for quick bonding, eliminating the need for drilling or welding.

- Invisible Bonding – Tapes and adhesives ensure a sleek, uninterrupted surface, unlike rivets and screws that disrupt the design.

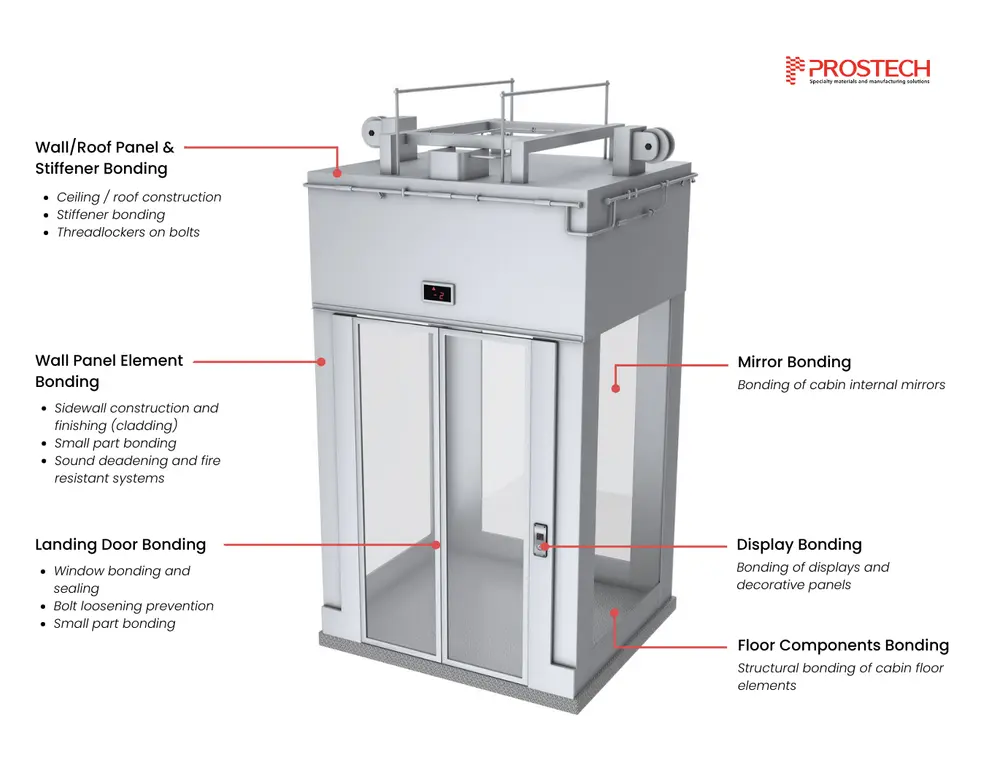

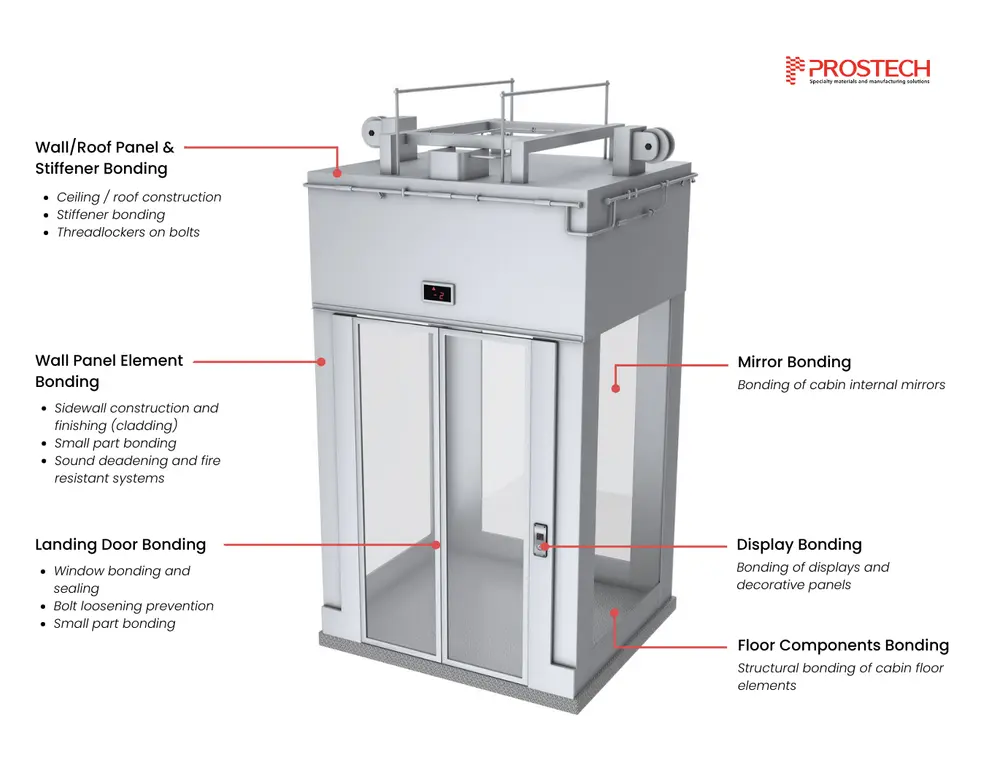

Bonding solution for elevator assembly

From cabin to door production, Prostech’s solutions support structural bonding for stiffeners and frames, secure displays and mirrors, assemble interior panels and plastic flooring, and reduce cabin vibrations. These advanced adhesives ensure durability, reliability, and a sleek, high-quality finish.

1. Display Bonding

Bonding Substrates: Displays in elevator cabins are typically glass, acrylic, or polycarbonate, mounted onto metal or plastic frames.

Benefits: Our adhesives and tapes ensure precise, clean bonding without the need for screws, which can damage delicate display materials. The use of optically clear adhesives enhances visibility while reducing the risk of air bubbles. These solutions also provide impact resistance and vibration damping, improving display longevity and performance.

Related article: Advanced Display Assembly Solutions – LED TVs, Interactive Meeting TV and Touch Screens

2. Door, Floor and Panel Element Bonding

Bonding substrates: Elevator doors and panels are made from stainless steel, aluminum, and high-pressure laminates (HPL) for enhanced durability and aesthetics.

Benefits: Traditional fastening methods like welding or rivets can distort the surface and require post-processing. Our high-performance adhesives and double-sided tapes create a seamless, secure bond without visible fasteners, preserving the design integrity. These solutions also help absorb vibrations, reducing noise during elevator operation.

3. Mirror Bonding in elevator assembly

Bonding Substrates: Elevator mirrors are usually glass or acrylic, fixed onto metal, composite, or wooden panels.

Benefits: Mechanical fasteners can cause stress points, leading to cracks in mirrors over time. Our specialized adhesives and tapes provide a secure, flexible bond that accommodates expansion and contraction due to temperature changes. They also improve safety by preventing shattering upon impact.

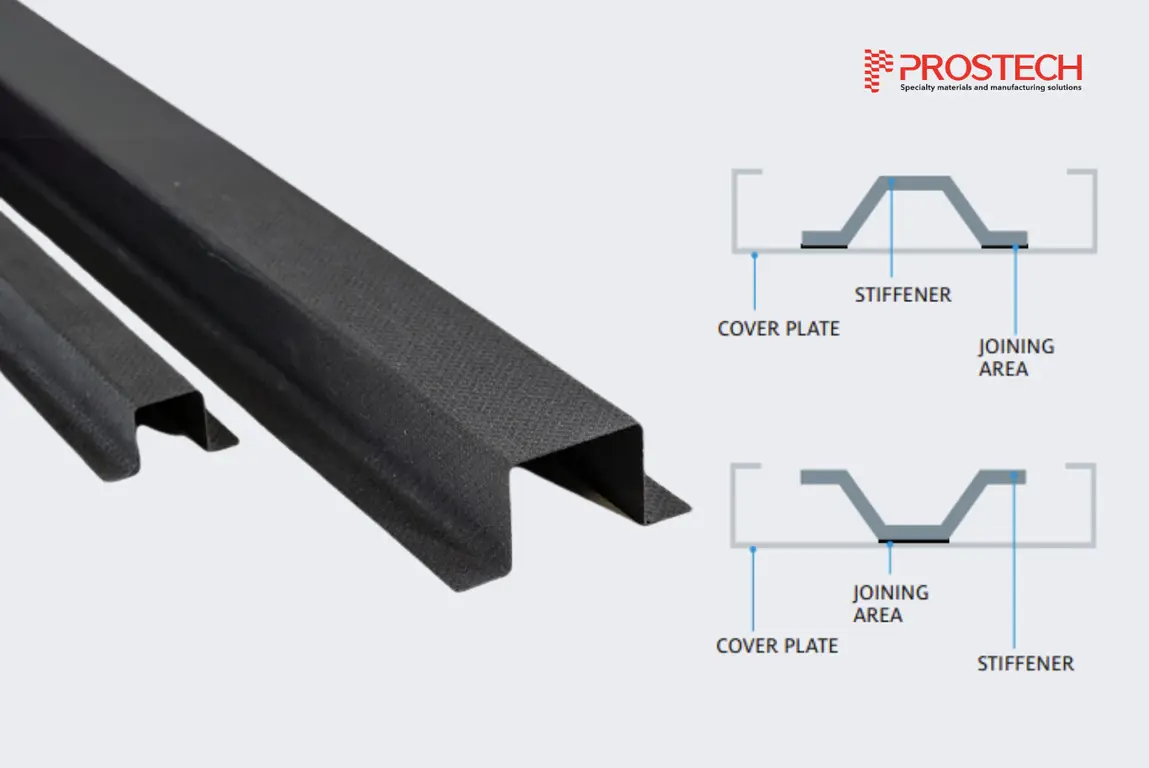

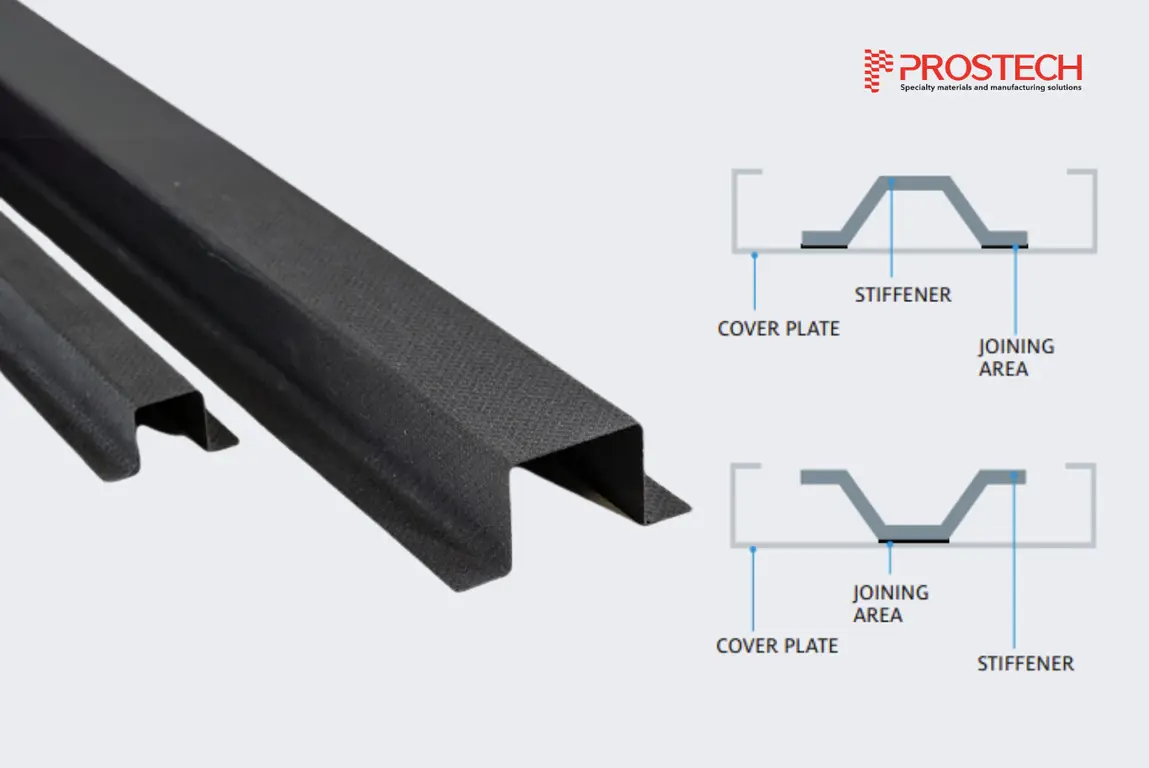

4. Bonding of Stiffeners and Reinforcement Bars (Wall, Door, and Roof Panel Stiffener Bonding)

Bonding: Stiffener bars are commonly made of raw aluminum, powder-coated aluminum, or steel, while panels are typically aluminum plates, stainless steel, or composite materials.

Benefits: Our adhesives and double-sided tapes provide strong, flexible bonding between stiffener bars and thin metal or composite panels. Unlike mechanical fasteners, they do not require drilling or welding, reducing material stress and eliminating the risk of corrosion. The use of tapes simplifies the assembly process, minimizes labor, and speeds up production by allowing fast, tool-free application.

5. Interior Panel Bonding in elevator assembly

Bonding Substrates: Interior elevator panels are made from stainless steel, aluminum, laminated surfaces, or composite materials.

Benefits: Using adhesives and tapes for panel bonding eliminates visible screws and rivets, creating a seamless, modern aesthetic. Our solutions enhance durability by preventing material fatigue and corrosion, while also allowing for easy application without the need for heavy tools.

Choosing the right adhesives and tapes depends on the substrates, application, and performance requirements. We offer a wide range of solutions tailored for various elevator assembly needs. Contact us for expert consultation to find the best bonding solution for your project.

Recommended Products for Elevator Assembly

Here are some of our top-performing adhesives and tapes designed to enhance durability, efficiency, and aesthetics in elevator manufacturing:

- Structural Adhesives – High-strength bonding for stiffeners, reinforcement bars, and metal panels.

- Double-Sided Tapes – Ideal for fast, clean bonding of interior panels, displays, and mirrors without visible fasteners.

- Vibration-Damping Adhesives – Reduce operational noise and improve passenger comfort.

- Flexible Adhesives – Provide shock absorption and thermal expansion tolerance for long-term performance.

| Products | Benefits |

ITW SM 2030 WHT |

|

|

|

|

|

3M 2552 Vibration Damping Tape |

|

Bostik 2405 |

|