On December 20, 2022, 3M announced its plan to exit per- and polyfluoroalkyl substance (PFAS) manufacturing and work to discontinue use of PFAS in its product portfolio by the end of 2025. 3M Novec, known for its innovative applications in fire suppression, cleaning, and cooling, is being phased out due to concerns over PFAS. The discontinuation of Novec products marks a significant shift for industries that rely on these solutions. What are the key factors driving the phase-out of 3M Novec, and what are the implications for industries that depend on it? Explore our article to find out!

What is 3M Novec?

3M™ Novec™ is a brand of advanced specialty fluids developed by 3M used for coating, cleaning, and lubrication. They are known as 3M Novec Engineered Fluids are a series of non-conductive, non-flammable, low-viscosity liquids that offer a range of unique properties and applications. Novec fluids offer a wide margin of safety, low GWP, and zero ODP with excellent performance.

Product lines of 3M Novec

- 3M Novec Engineered Fluids are appropriate for various uses that require cleaning, heat transfer, and other applications. These fluids possess a broad spectrum of boiling points, low viscosity, and high dielectric strength.

- 3M™ Novec™ Aerosol Cleaners are 95% active solvents with excellent cleaning performance. It is non-corrosive and non-conductive, penetrates deep into tight spaces, is fast drying, and leaves no residue.

- 3M Novec Electronic Grade Coatings: protect sensitive electronics against harmful factors with a very thin layer. They provide excellent anti-wetting, anti-stiction, anti-migration and anti-corrosion properties.

- 3M™ Novec™ Insulating Gases are being used in cutting-edge gas-insulated lines and gas-insulated power equipment, helping electrical power industry leaders meet their goals for a sustainable future.

Some typical Novec products:

|

|

|

|

| 3M Novec 7100 Engineered Fluid | 3M Novec Flux Remover | 3M Novec 2704 Electronic Grade Coating |

Applications of 3M Novec

3M Novec products serve in applications such as fire suppression systems, electronics cooling, and precision cleaning. It is widely used across various industries:

- Aerospace, Aviation, and Military

- Medical Devices:

- Automotive & Transportation

- Data Center and Telecommunications

- Electronics

- Film Cleaning

- Semiconductor

- Marine

Reasons for 3M Novec Phase-Out

The portfolio decision is based on careful consideration and a thorough evaluation of the external landscape, including multiple factors such as accelerating regulatory trends focused on reducing or eliminating the presence of PFAS in the environment and changing stakeholder expectations.

PFAS Concerns

PFAS is restricted in worldwide scope due to its impacts on the environment. 3M Novec contains PFAS (per- and polyfluoroalkyl substances), which are persistent in the environment and linked to significant health and ecological risks, including contamination of water sources and harm to wildlife.

To find out more information about 3M PFAS and alternative solutions, you can refer to this article: Discontinue 3M PFAS- How to reduce the impact for Novec users?

Current PFAS Restriction Situation

Tens of thousands of PFAS are possible with many different uses. PFAS appears in countless products used all around us, from non-stick pans to clothing and cosmetics. Among them are applications where PFAS cannot be replaced.

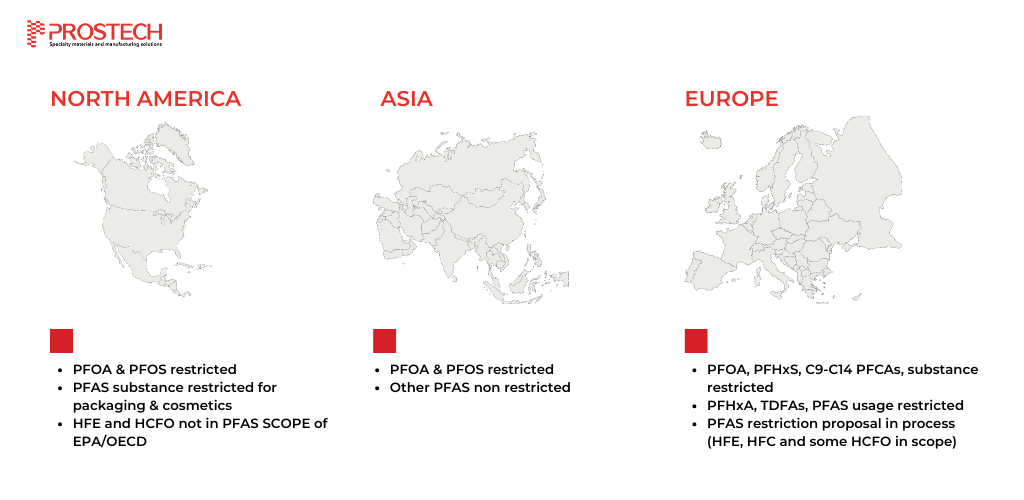

Although PFAS is under proposal for restricted use, it is important to understand that not all PFASs are harmful to the environment or dangerous to humans. Only certain substances, such as PFOS and PFOA, are receiving special attention because of their presence in so many applications with the potential for harm. Therefore, the immediate removal of PFAS entirely is now almost impossible.

This means that the review of the decision to restrict the use of PFAS does not imply a restriction on the use of 3M Novec. Restrictions also vary by region or country:

Source: Perfluoralkylchemikalien (PFAS)

Restrictive regulations being reviewed by environmental agencies on the use of PFAS are just one of the reasons why 3M phased out Novec. 3M also faces global supply challenges, along with strong industry demand exceeding current capacity. All of this resulted in a worldwide shortage of 3M Novec solvents as well as escalating prices for this solvent line.

3M’s Decision

These combined issues made it increasingly difficult to sustain the product line, prompting 3M to discontinue Novec as part of its broader move to eliminate PFAS from its offerings by 2025.

The Impact of the 3M Novec Phase-Out on Industries

The phase-out of key chemicals has placed significant pressure on various industries to quickly identify and adopt alternative solutions. This transition is not just a regulatory challenge but an urgent necessity for maintaining operational efficiency and compliance. As a manufacturer that uses solvents in the production process, you may understand that when switching to a new solvent, not only the cleaning performance must be evaluated, but also the compatibility of the new solvent with equipment and processes.

Each manufacturer requires materials and products with unique features for the production processes, but many criteria must be taken into consideration to choose the right type of replacement. You can refer to this article to find out the key criteria for qualifying for 3M Novec replacement: Key Criteria for Choosing 3M Novec Replacements

3M Novec Replacements Solution

If you are looking for your specific alternative solvents, Prostech has both temporary and long-term replacement solvents that can solve your current manufacturing problems, both supply chain and technical requirements:

- Direct replacement solvent for 3M Novec does not require cleaning performance testing.

- PFAS-free long-term Novec solvent replacement with improved cleaning performance and cost-effectiveness

- Other methods for industrial cleaning and degreasing

For a detailed overview of options for 3M Novec replacements, check out our blog: 3M Novec replacements – Drop-in and long-term solution

Download our 3M Novec and Fluorinert replacement guideline to find out how our innovative solutions can help you adapt to the phase-out seamlessly:

Prostech understands the technical issues related to industrial materials. We offer a complete range of solutions, including consulting, materials, and automation equipment. We have a nationwide network of storage facilities and provide support for logistics procedures. Positioned as a comprehensive supplier, Prostech is committed to becoming a trusted partner for manufacturers in the international market. Please contact us by leaving your information below: