During the production process, several issues can arise when bonding surfaces. These include weak bonds, adhesive failing to wet the surface, or corrosion after bonding. Let’s explore why these problems occur and how proper surface preparation can prevent them.

The Crucial Role of Surface Preparation

While adhesive quality is important, inadequate surface preparation is a frequent culprit behind bonding failures. Adhesives bond to the surface itself, not to contaminants. If the surface isn’t clean and free of impurities, the adhesive will bond to the contaminant layer, resulting in a weak connection.

Another factor is surface energy. Adhesives need materials with higher surface energy to spread and form a strong bond. Low surface energy materials cause the adhesive to bead up instead of spreading out, compromising adhesion.

A rough surface offers a larger bonding area compared to a smooth one. This increased surface area allows for stronger adhesive forces, leading to a more robust joint. Therefore, proper surface preparation is essential for maximizing bond strength.

Benefits of Proper Surface Preparation

- Improved functionality and mobility: A strong bond ensures the product functions as intended.

- Enhanced comfort and reduced skin irritation: Proper adhesion minimizes the risk of irritation from a loose-fitting component.

- Increased durability and longevity: A strong bond extends the lifespan of the product.

- Improved user confidence and satisfaction: A reliable product instills confidence in the user.

Surface Treatment Methods

There are two main surface treatment methods: chemical and physical. Depending on the specific requirements, one or a combination of these methods may be used.

I. Chemical treatments

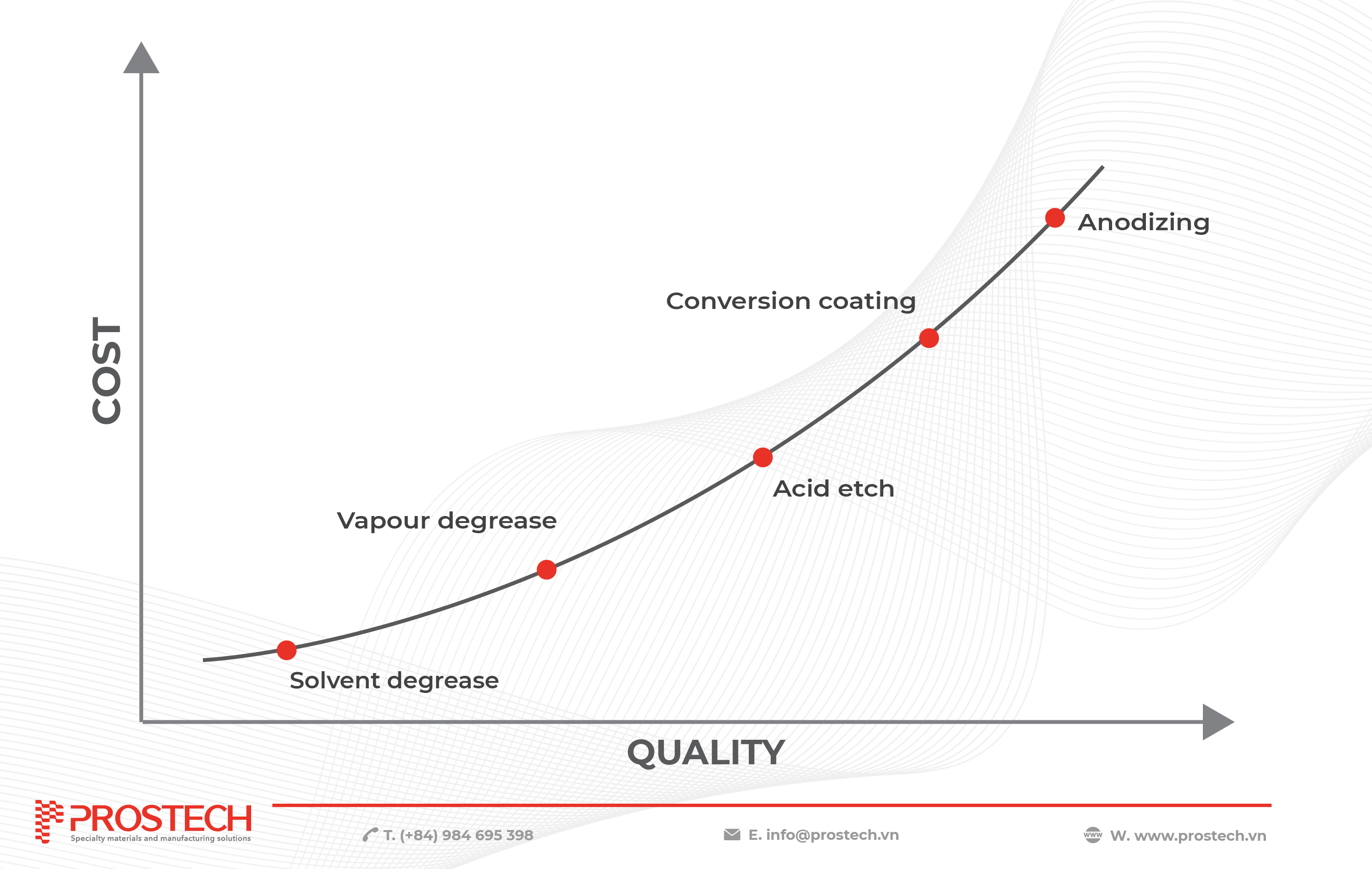

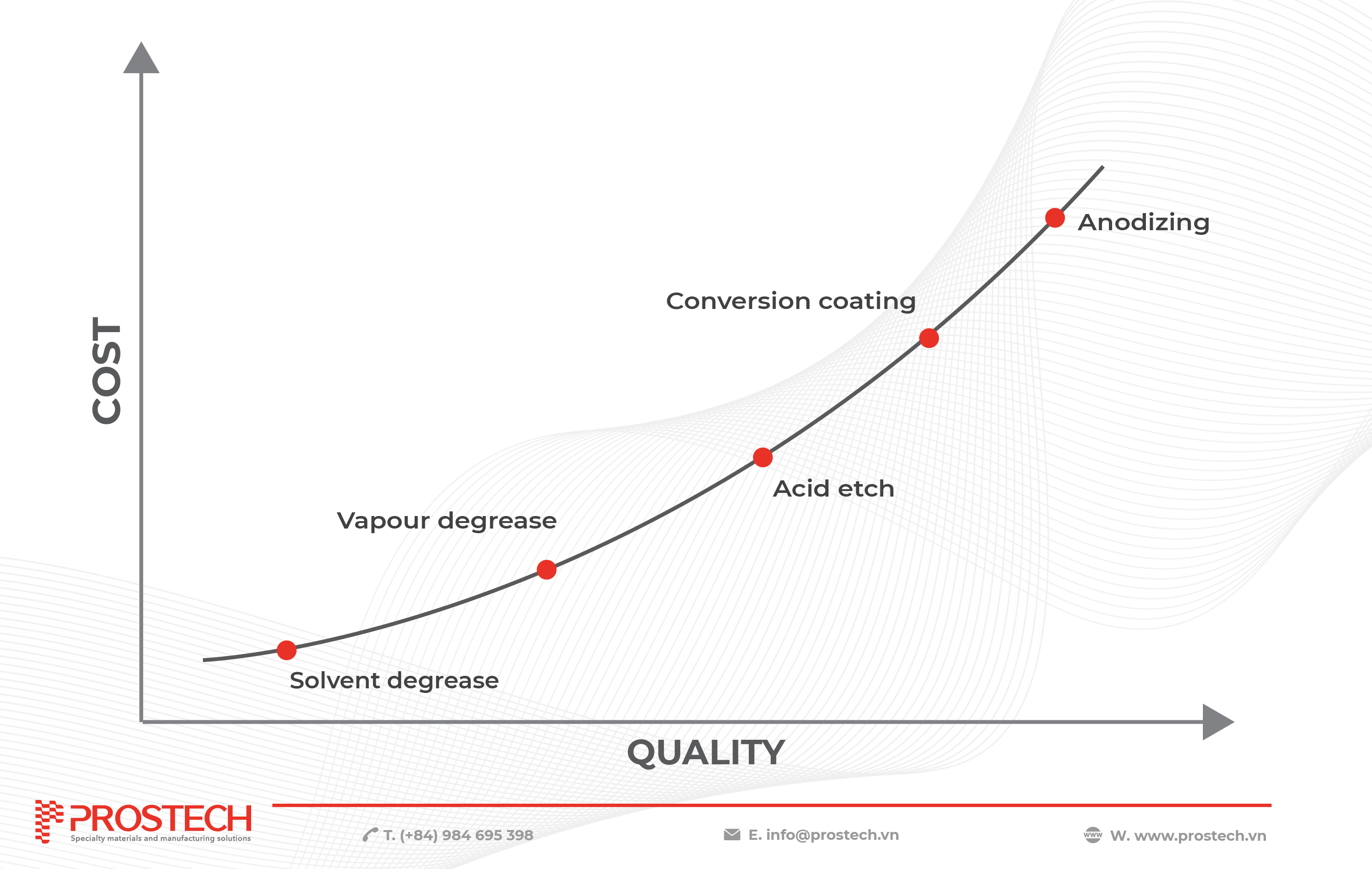

1. Solvent degreaser

This is one of the simplest methods of surface preparation. Solvent is manually applied using rags or immersion degreasing baths. However, this method requires a large amount of solvent since it needs to be changed continuously to avoid cross-contamination. The advantage of this method is its simplicity, ease of use, and no need for investment in machinery. However, it has many limitations as it cannot alter the physical and chemical properties of the surface, only cleaning the exterior. Additionally, solvents are harmful to the environment and human health. Solvents are being developed to be halogen-free to protect the environment.

Learn more about our halogen-free and environmentally friendly solvent degreasers HERE.

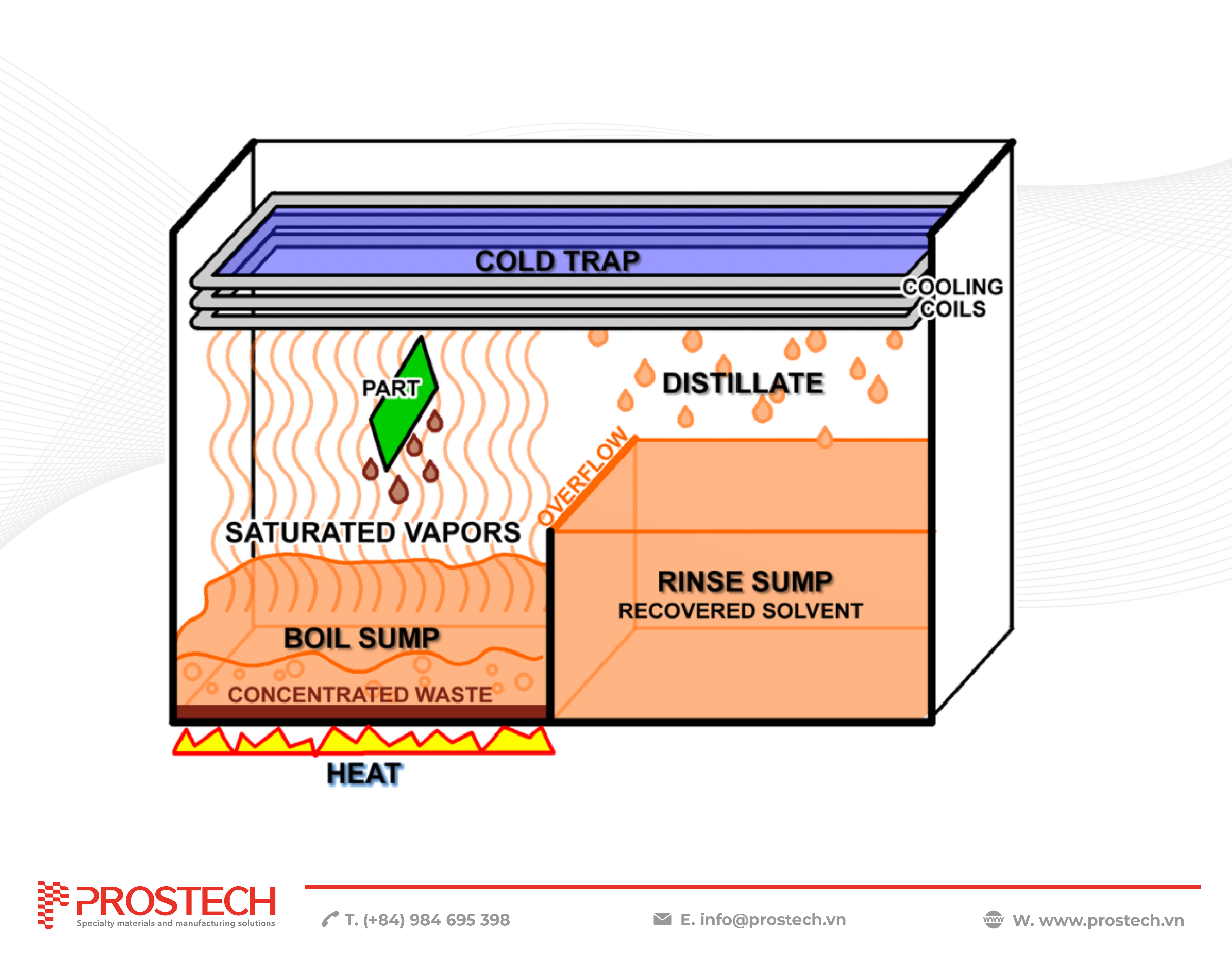

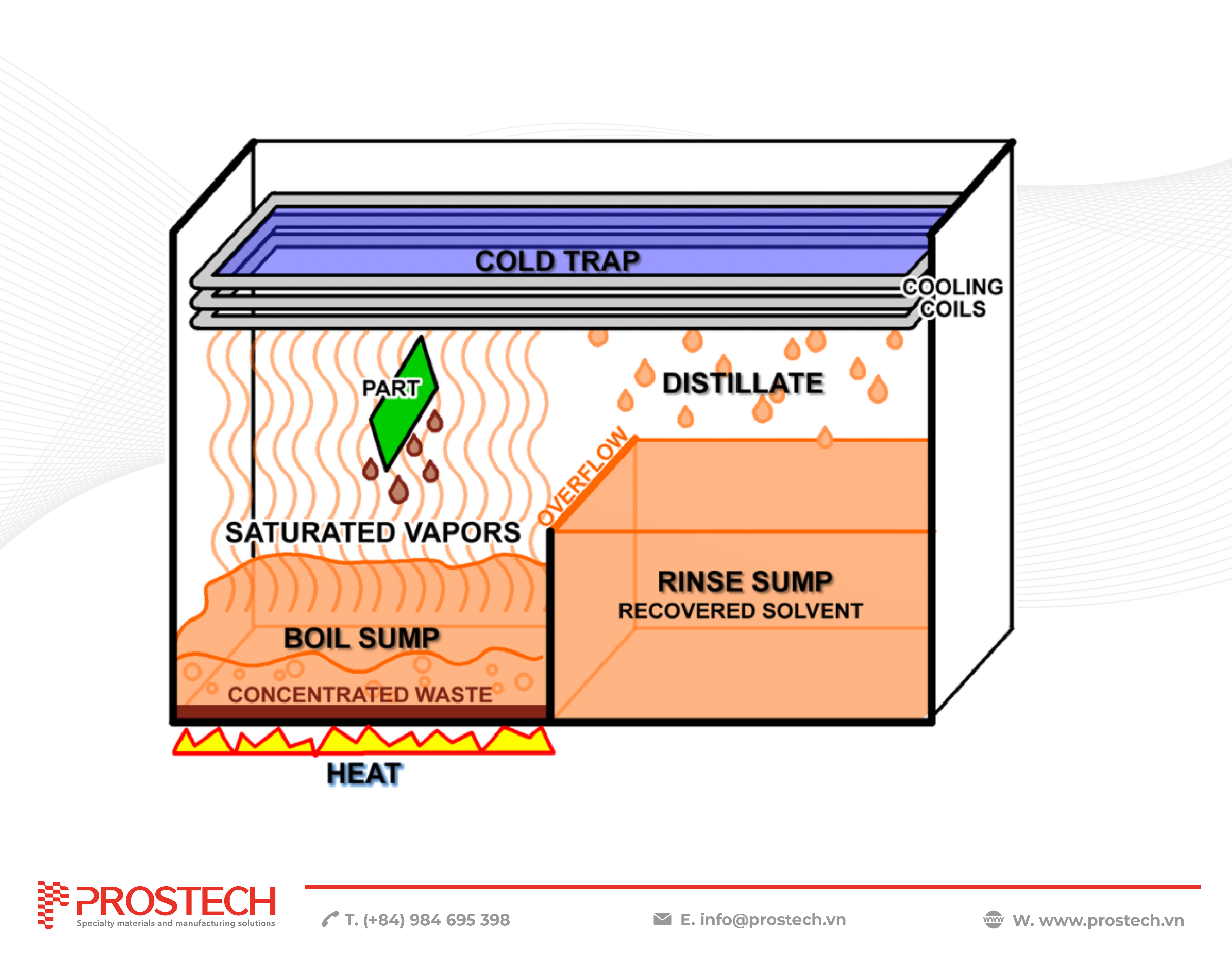

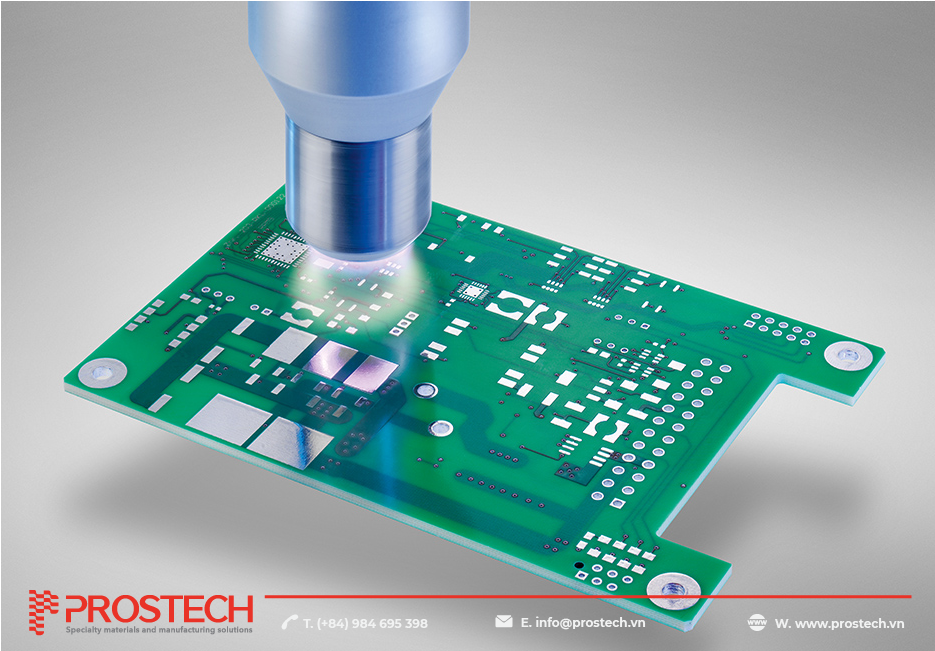

2. Vapor degreaser

Vapor degreasing involves condensing solvent vapors on the object being cleaned. This process does not require water or scrubbing. Instead, the vapor-degreasing machine uses solvent vapors to cleanse and remove contaminants from parts. This method is used to clean various materials during the manufacturing process, such as plastic, glass, metal, gold, and ceramic. The benefits of vapor degreasing include excellent cleaning results, repeatability, and independence from operator techniques and manual cleaning methods. The use of vaporized solvent avoids cross-contamination, a common issue with methods that reuse solvents or cleaning solutions from part to part. The use of solvents also allows for quick drying without a secondary drying process.

Although vapor degreaser solvents are generally expensive compared to other cleaning materials, they are continuously recycled in the closed-loop process, making it an economical method over time. Additionally, compared to batch or inline systems common with aqueous cleaners, vapor degreasing does not require heating water, rinsing, drying parts, or treating wastewater post-cleaning.

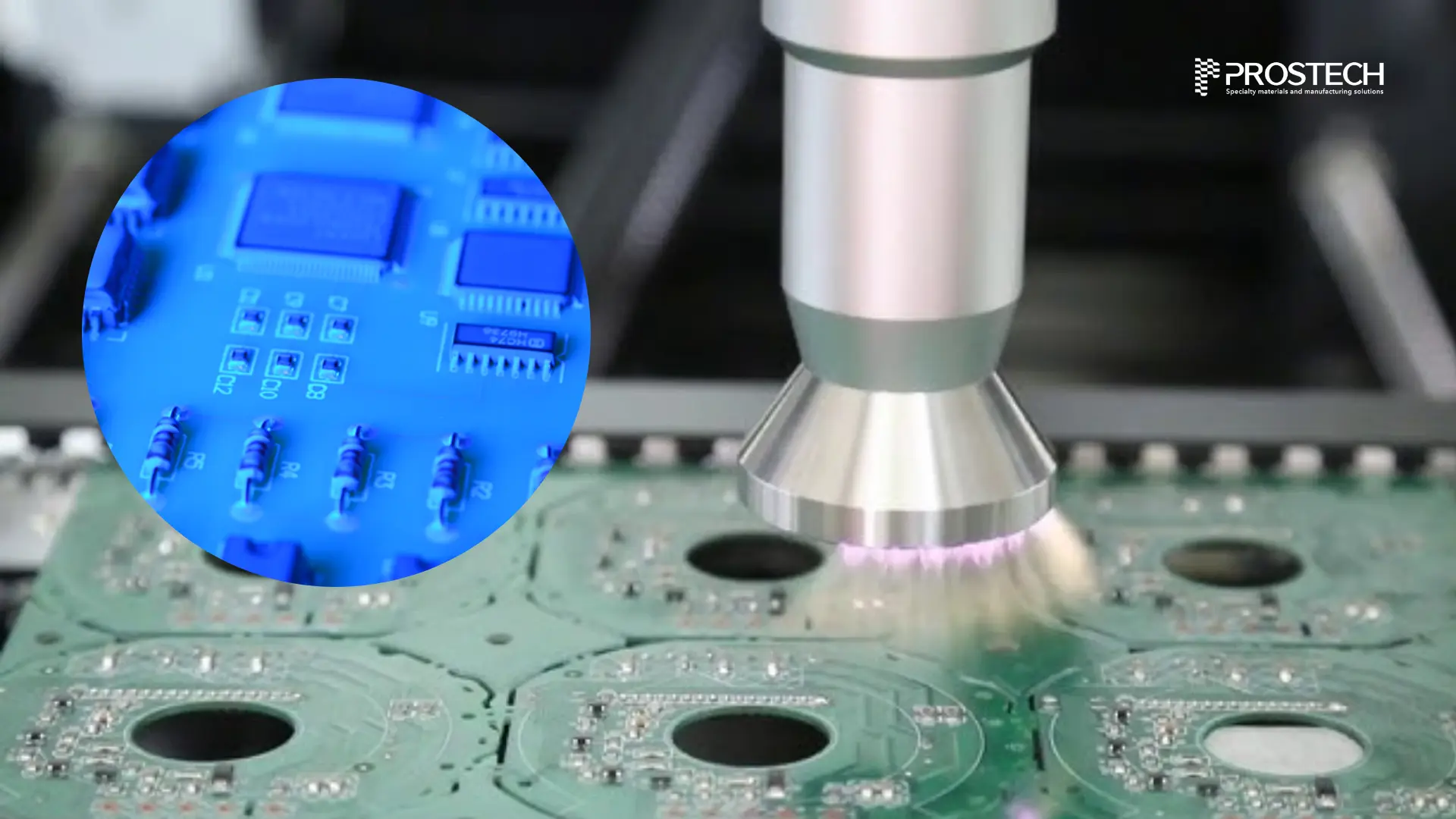

Prostech provides both degreaser solvent and vapor for PCB cleaning process, contact us for more consultation.Achieve optimal PCB cleaning with Prostech’s degreaser solvents and vapors. Contact our experts for a free consultation!

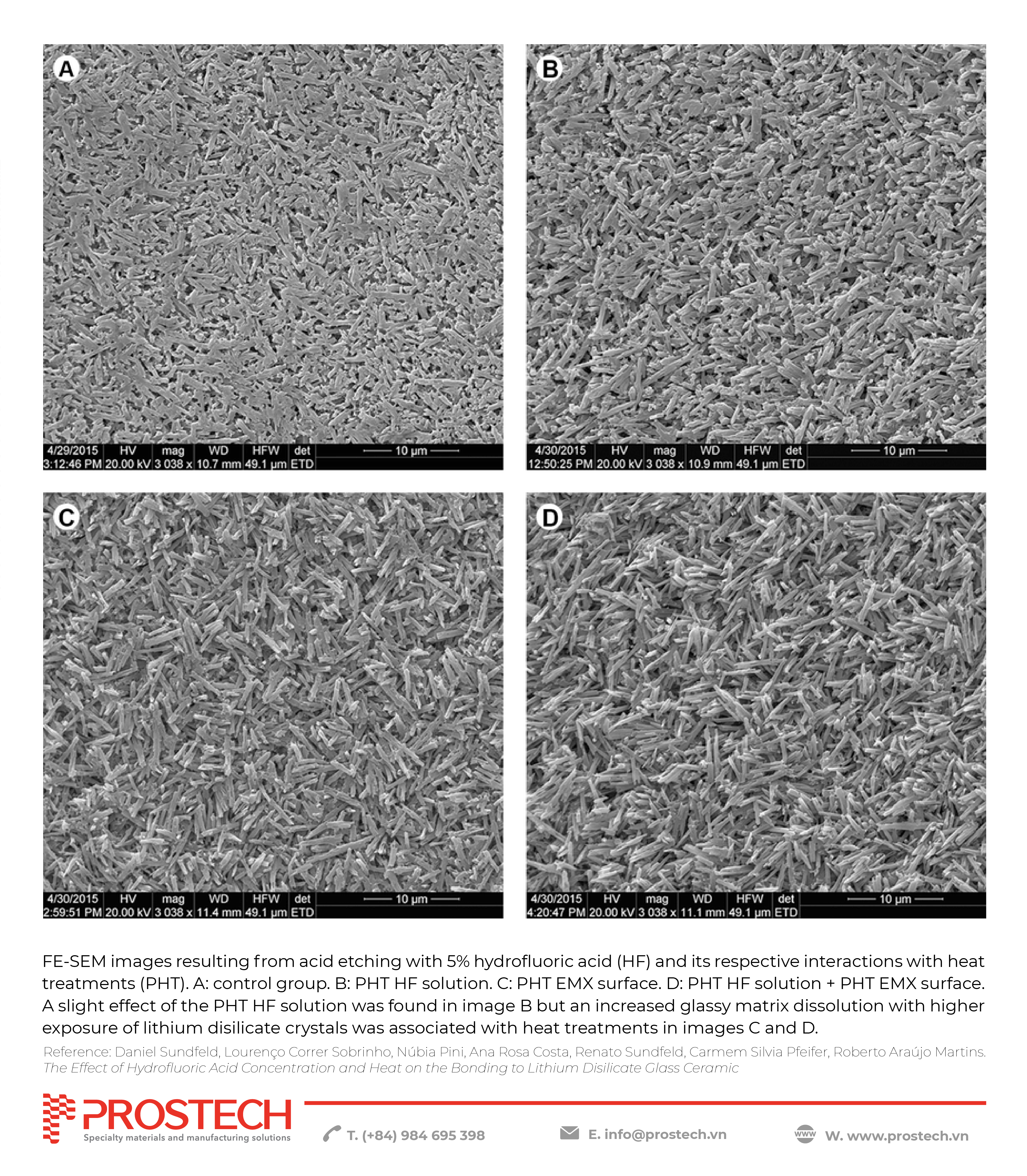

3. Acid etch and Anodizing

Acid etching involves immersing a metal substrate in an aqueous acid solution to remove a loose layer of oxide from its surface. The specific acid used depends on the metal and type of oxide being treated. In many cases, acid etching may provide enough surface preparation for bonding, depending on the desired degree of adhesion. Acid etching can also be effectively used with certain plastics, such as treating polyolefins with chromic acid. Anodizing involves the electrochemical modification of the surface, depositing a porous and stable oxide layer on top of the oxide layer formed after etching.

These two methods are usually the last steps in the sequence of surface preparation processes and are only used when maximum strength and permanence are required in a joint. They are always preceded and followed by surface cleaning via one of the processes defined in the last section. These treatments provide improved bond strength and durability through several processes:

- Removing the weak boundary layer or modifying it to provide a strong, well-bonded, stable layer receptive to adhesives.

- Increasing the surface energy of the natural surface so it is higher than that of the adhesive used (primarily for polymeric surfaces).

- Protecting the surface or providing a new surface more resistant to environmental influences once the joint is in service.

4. Conversion coating: Primer & adhesion promoter

Primers and adhesion promoters work similarly to improve adhesion. They add a new, usually organic, layer at the interface. This new layer can be bifunctional and bond well to both the substrate and the adhesive or sealant. The new layer is thin, providing improved interfacial bonding characteristics without significantly affecting the bond’s overall properties.

Both primers and adhesion promoters are strongly adsorbed onto the substrate’s surface. This adsorption may be so strong that it resembles a chemical bond rather than mere physical adsorption. The main difference between primers and adhesion promoters is that primers are liquids applied to the substrate as a relatively heavy surface coating before applying the adhesive. In contrast, adhesion promoters (coupling agents) form a very thin (usually monomolecular) layer between the substrate and the adhesive. Adhesion promoters are not only used to improve substrate adhesion but also to modify the surface properties of internal fillers for better wetting and adhesion.

Leveraging our extensive experience in providing adhesive solutions for manufacturing, Prostech is confident in offering high-quality primers and adhesion promoters. These products are formulated to effectively address a wide range of substrates and surfaces, including even those traditionally difficult to bond. Contact us today or browse our selection of primers HERE.

II. Physical treatments

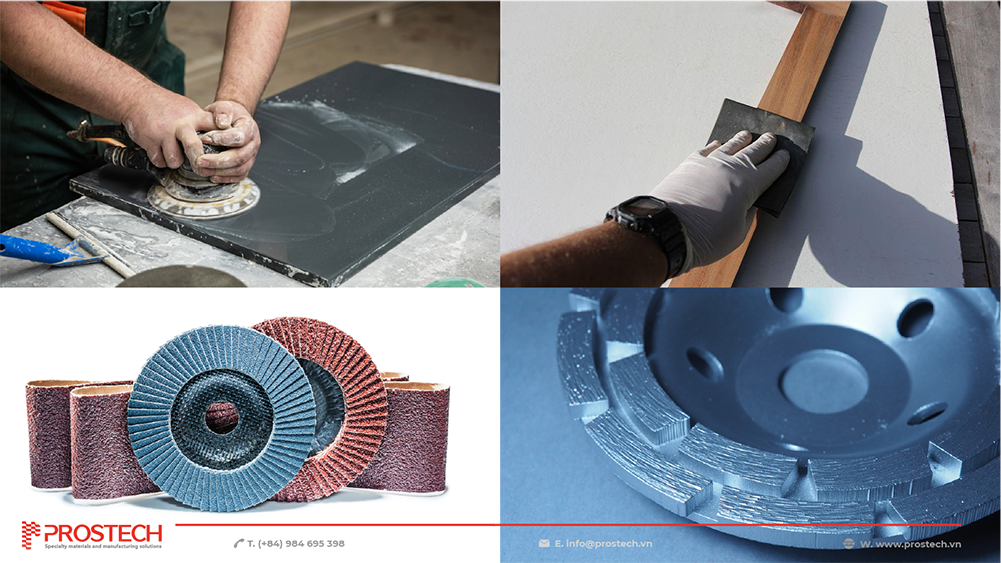

1. Mechanical abrasion

Mechanical abrasion is the most traditional method for changing the physical properties of a surface. Workers rub the surface of substrates by hand or equipment to make them rougher. While simple and easy to implement, this method has many limitations, such as damaging the substrate surface, consuming a lot of labor, taking a long time, and not guaranteeing the required standards.

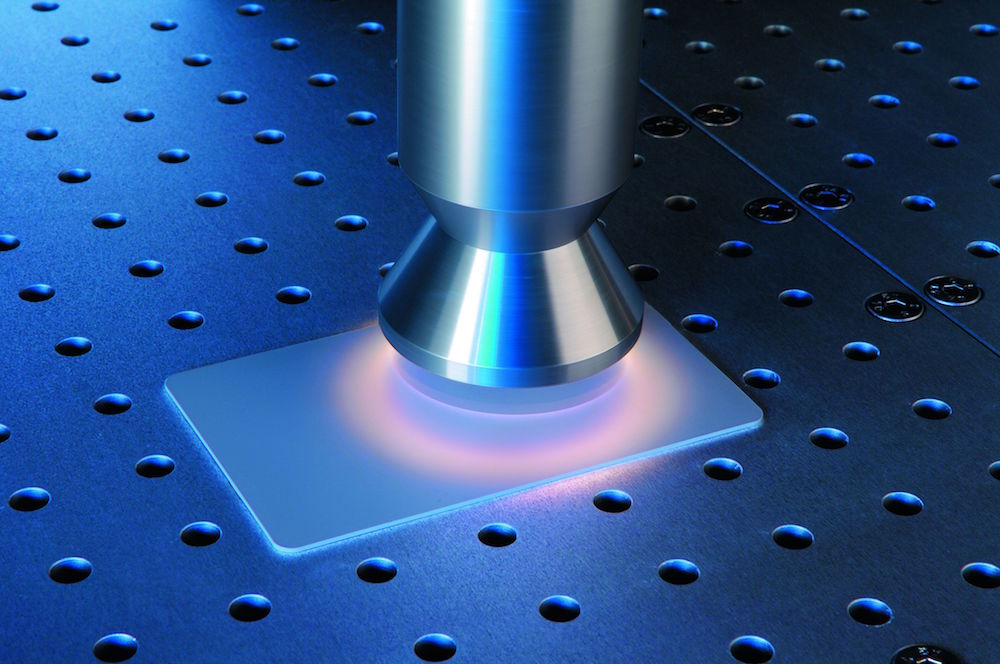

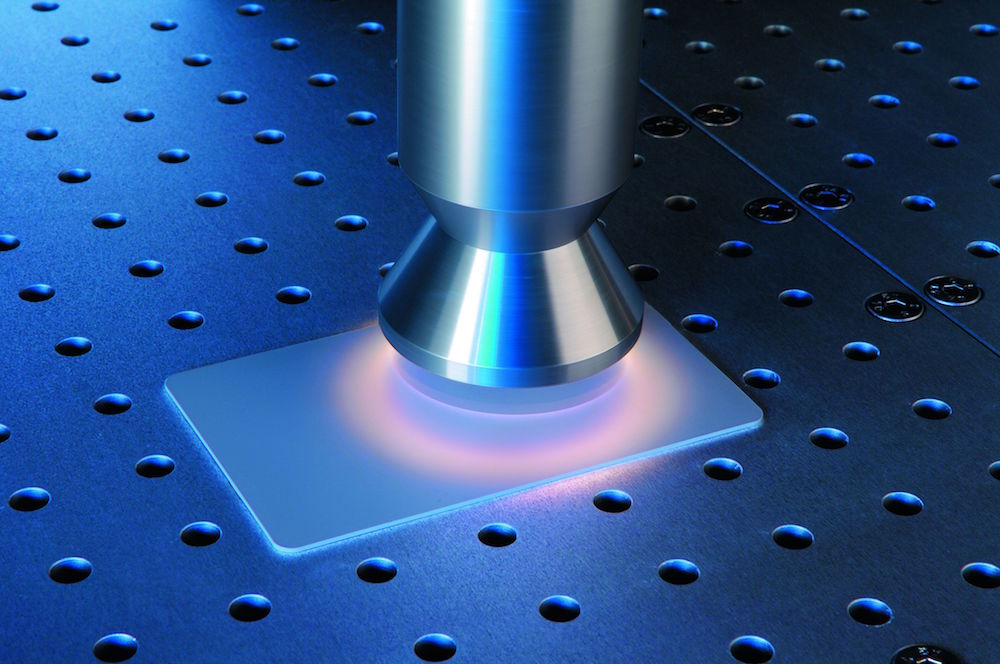

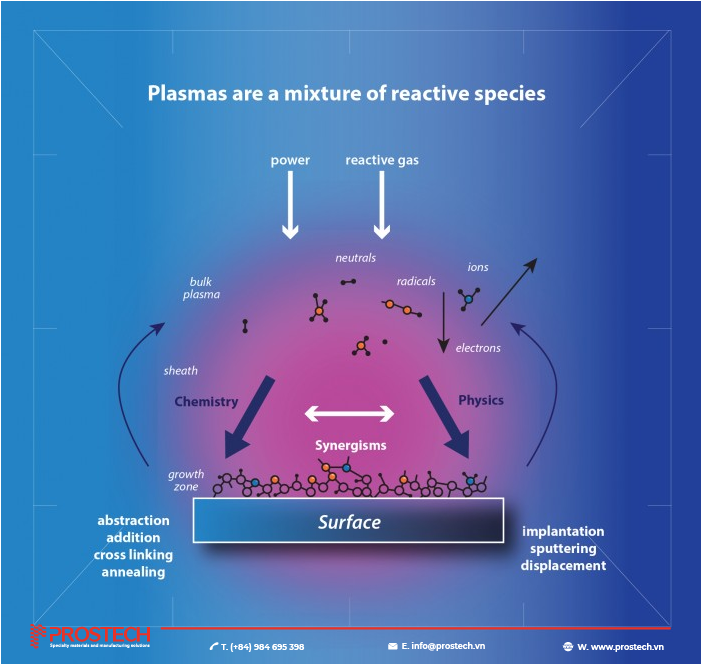

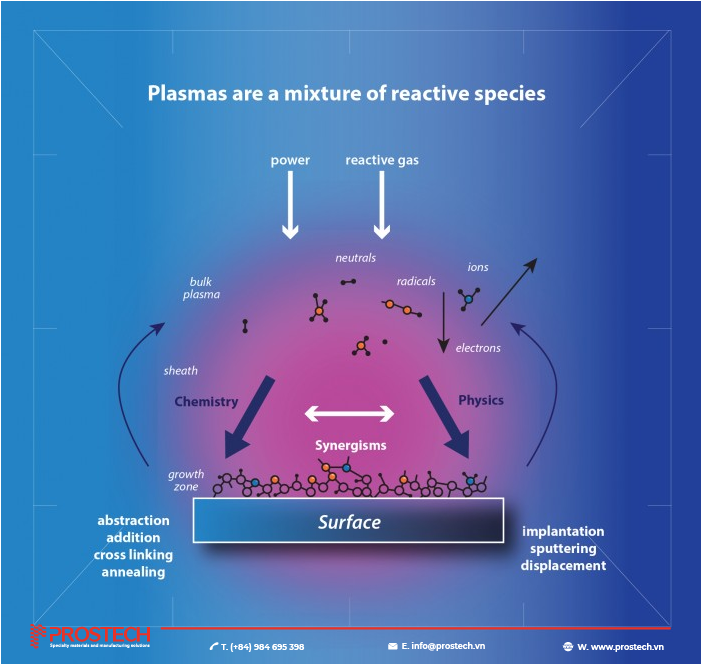

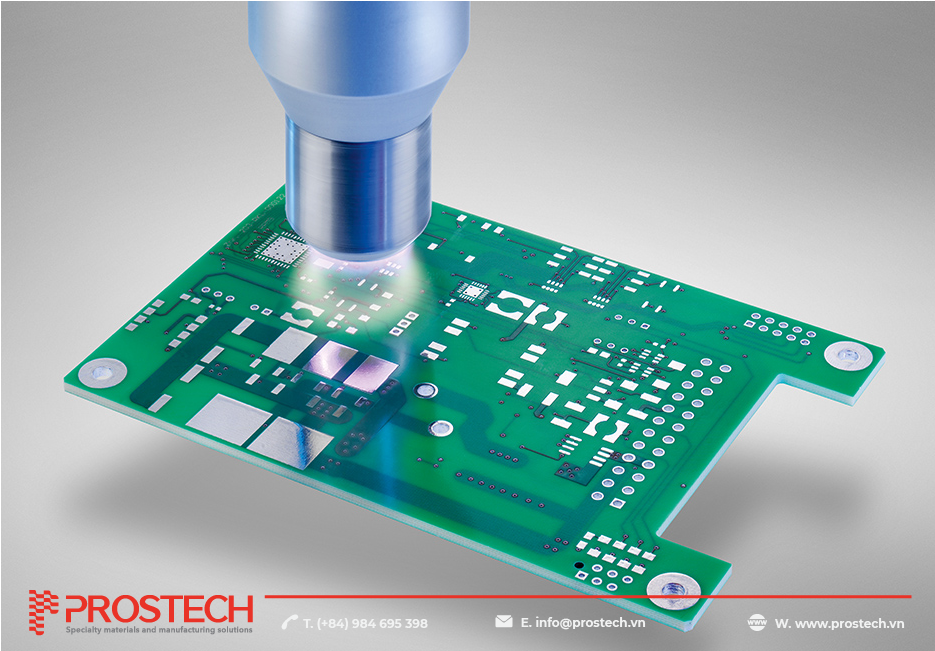

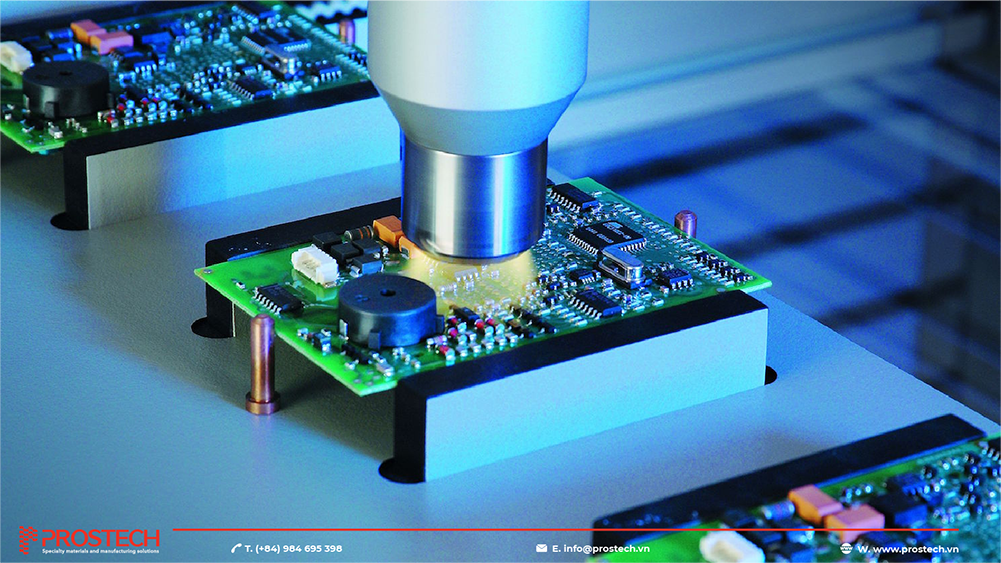

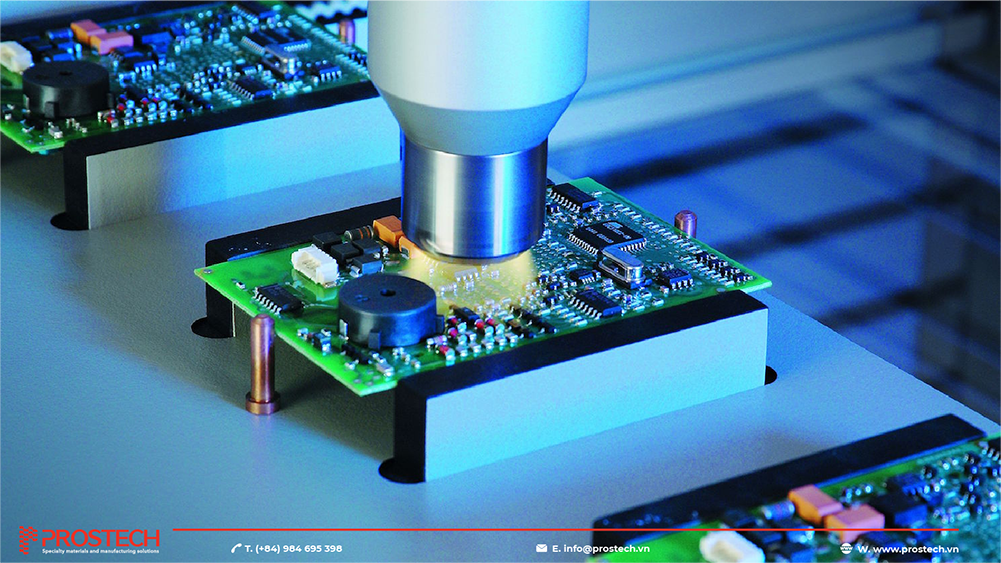

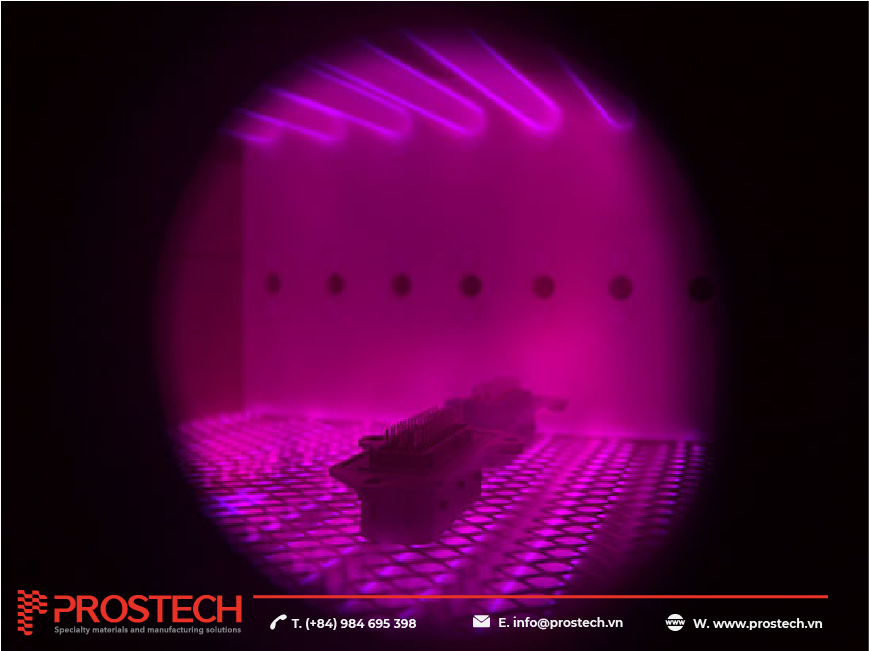

2. Plasma

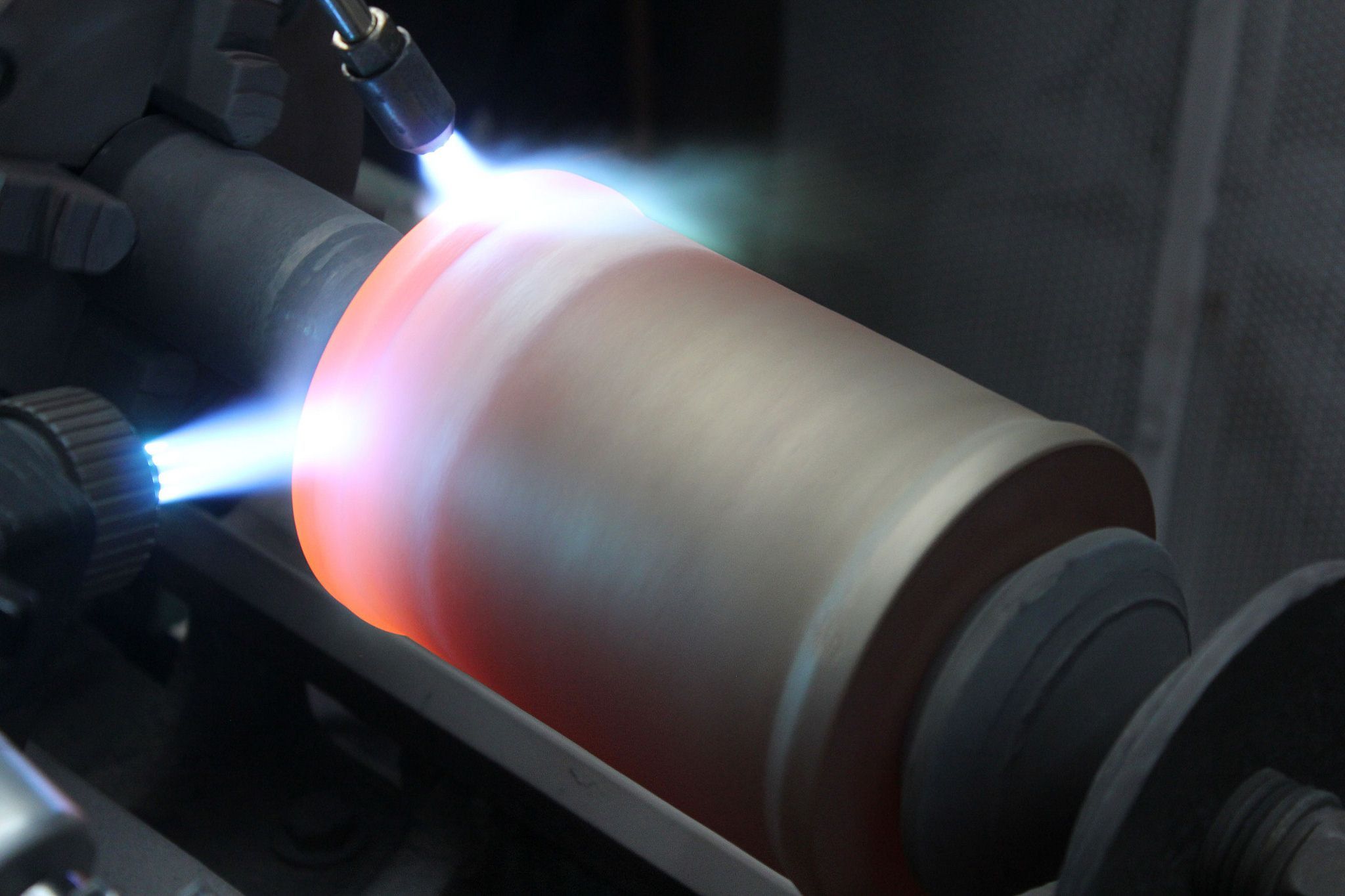

Plasma is essentially a state of matter besides solid, liquid, and gas. By adding enough energy to gas molecules, they become ionized (lose one or more electrons) and carry a net positive charge. Plasma, often referred to as the fourth state of matter, contains positive ions, electrons, neutral gas atoms or molecules, UV light, and excited gas atoms and molecules, all carrying significant internal energy. These components interact with the surface during plasma treatment. By selecting the gas mixture, power, and pressure, the effects of plasma treatment can be precisely tuned.

Read more: What is Plasma Surface Treatment and how does it work on the surface?

Plasma technology plays an increasingly important role in product fabrication due to its unique properties:

- Ability to treat complex 3D objects and micro-channels that are hard to reach with standard methods.

- Plasma is a chemical-free cleaning process, making it environmentally friendly.

- Easily increases surface energy in one step.

- Can treat temperature-sensitive materials.

- Treats conductors, semiconductors, and insulators that are small and delicate and difficult to bond.

- Cost-saving with a very low unit cost per treatment.

- Produces high value-added properties to the product.

Discover the benefits of Plasma surface treatment in this informative article: Benefits of using Plasma in Surface Treatment Process

Plasma has four main functions:

- Plasma Cleaning

Plasma cleaning is a proven, effective, economical, and environmentally safe method for critical surface preparation. Plasma cleaning with oxygen plasma eliminates natural and technical oils and grease at the nano-scale and reduces contamination up to six-fold compared with traditional wet cleaning methods, including solvent cleaning residues. Plasma cleaning produces a pristine surface ready for bonding or further processing without harmful waste material.

- Plasma Surface Activation

Low energy substrates are gaining popularity in many manufacturing processes due to their benefits such as durability, flexibility, and cost-effectiveness. While adhesives have adapted to challenges posed by low surface energy, plasma treatment effectively pre-treats surfaces for printing, lacquering, or bonding. Glass and ceramics can also be plasma-activated similarly.

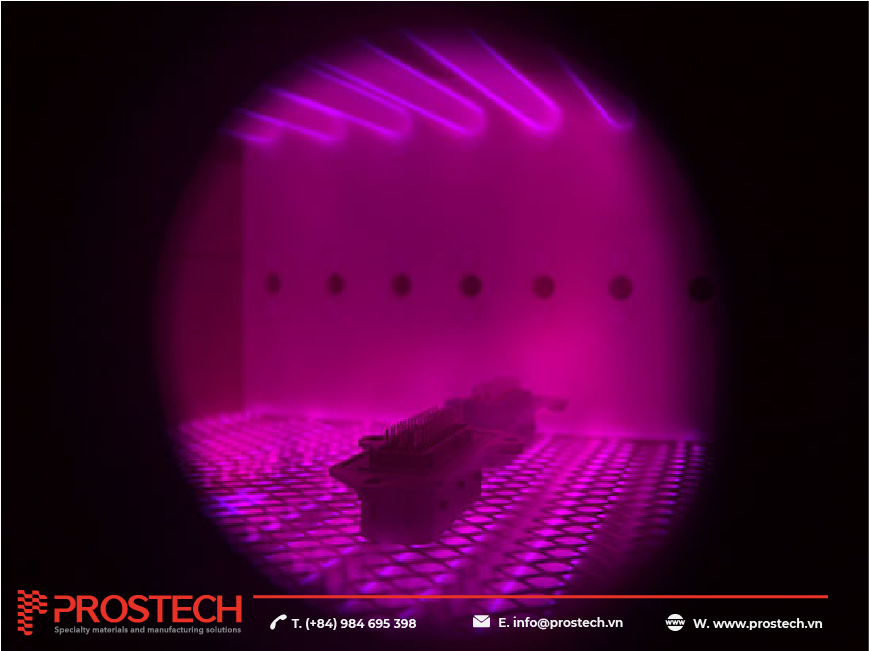

- Plasma Coating

In plasma coating, a nano-scale polymer layer is formed over the entire surface area of an object placed in the plasma. This coating process takes just a few minutes, producing a layer typically less than 1/100th the thickness of a human hair. The coating is colorless, odorless, and does not affect the material’s appearance or feel. It is a permanent coating, bound to the material surface on an atomic scale.

- Plasma Etching

Plasma etching ‘roughens’ a surface on a microscopic scale. The component’s surface is etched with a reactive process gas, removing material precisely and increasing the surface area, making it more wettable. This process is used before printing, bonding, and painting and is particularly useful for processing materials like POM and PTFE, which cannot otherwise be printed on or bonded.

Prostech, with many years of experience in the adhesive industry, provides a full range of surface treatments. Contact us to learn more about how our solutions can improve your production process and ensure the highest quality bonds: