As a safety-critical component, automotive lighting must serve two purposes – to see and be seen. To help avoid accidents, headlights, tail lamps, and brake lights should provide excellent visibility for the driver and ensure that other motorists and pedestrians can see you, even in conditions where visibility is reduced.

To be a reliable partner in the lighting industry, PROSTECH remains a leading partner for new cost-effective solutions for our customers. Our adhesives have been used on headlamps, tail lamps, and signal lamps on vehicles manufactured all over the world.

Automotive Lighting Solutions

From headlight housing sealants that offer improved adhesion and weather protection to tail lamps and headlight bonding products used in various light source assemblies, including light bulbs, halogen, Xenon, LED, and laser. PROSTECH offers an extensive portfolio of headlight sealant adhesives and automotive lighting solutions for the following areas:

- Housings

- Head/Fog Lights

- Tail/CHMSL Lamps

- LED Control Modules

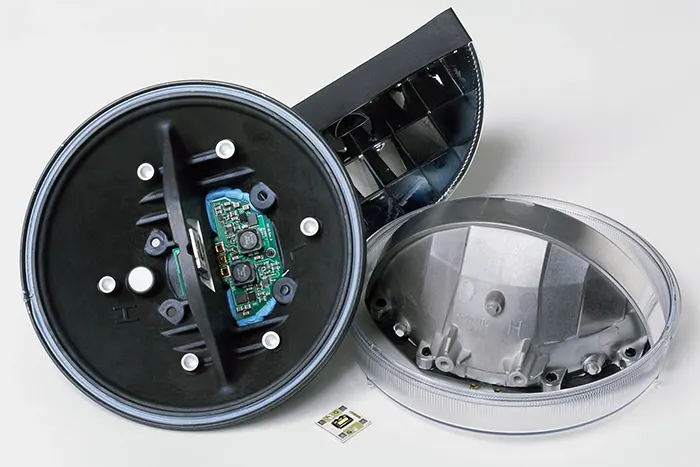

Housings

Strength and durability are key when it comes to headlight(headlamp) adhesives. Our high quality headlight bonding and headlight sealant adhesives are the ideal choice when bonding lens to housing units and lens cover gasketing. Not only do the headlight (headlamp) adhesives prevent fogging and condensation from forming in the light, but our range of headlight housing sealants also offer high temperature resistance and excellent adhesion Strength.

Head/Fog Lamps

Head Lamps and fog lamps are both located on the front of a vehicle. However, they serve two slightly different purposes. Head lamps are used to illuminate the roadway and facilitate fatigue-free and safe driving, while fog lamps are bright secondary lights, that are low mounted and used in foggy conditions to improve road visibility and warn other drivers. Henkel’s headlight (headlamp) adhesives provide reliable and strong solutions for headlight bonding applications including lens to housing bonding, as well as headlight sealant adhesives for lens cover gasketing.

Tail/ CHMSL Lamps

Tail and center high-mounted stop lamps (CHMSL) illuminate the rear end of the vehicle and incorporate brake lights that brighten when the brakes are applied. Signal lights or turn lights are also part of the rear lamp assembly. Because these lights play such an important safety role, it is vital that adhesives and sealing and bonding products used in Tail/CHMSL lamps can withstand vibrations and environmental conditions such as extremely high or low temperatures.

With high temperature resistance and improved adhesion, Henkel’s range of automotive lighting adhesives and sealants offer excellent reliability for applications such as bonding lens to housing unit and lens cover gasketing.

LED Control Modules

LED lighting is increasingly being used in more vehicles, especially with the development of smart headlamp systems where high-efficiency LED drive solutions are required. These include innovative technologies such as adaptive LED headlight systems and bend lighting control. However, there are challenges to implementing automotive LED lights. The small and low-power-consuming LED modules require thermal management, as well as protection against electromagnetic interference (EMI). For this reason, we offer robust and reliable automotive lighting solutions that include thermal management materials, solder pastes, underfills, and electrically conductive headlight (headlamp) adhesives that are ideal for bonding LED heat sinks, as well as for connectors and wire molding.