Covid-19 occurred, causing factories to be locked down, unable to produce without labor. So an entire economy was halted. This is a challenge but also an opportunity for factories to shift to fully autonomous production.

According to market research company Frost & Sullivan, factories can save up to 20% in labor costs and generate a 30% increase in productivity by switching from manual production to an automated factory model. Also according to the director of Techvision of Frost & Sullivan, replacing human power with machines will help companies increase unlimited working hours, thereby get more new orders, and be more productive than before the Covid epidemic.

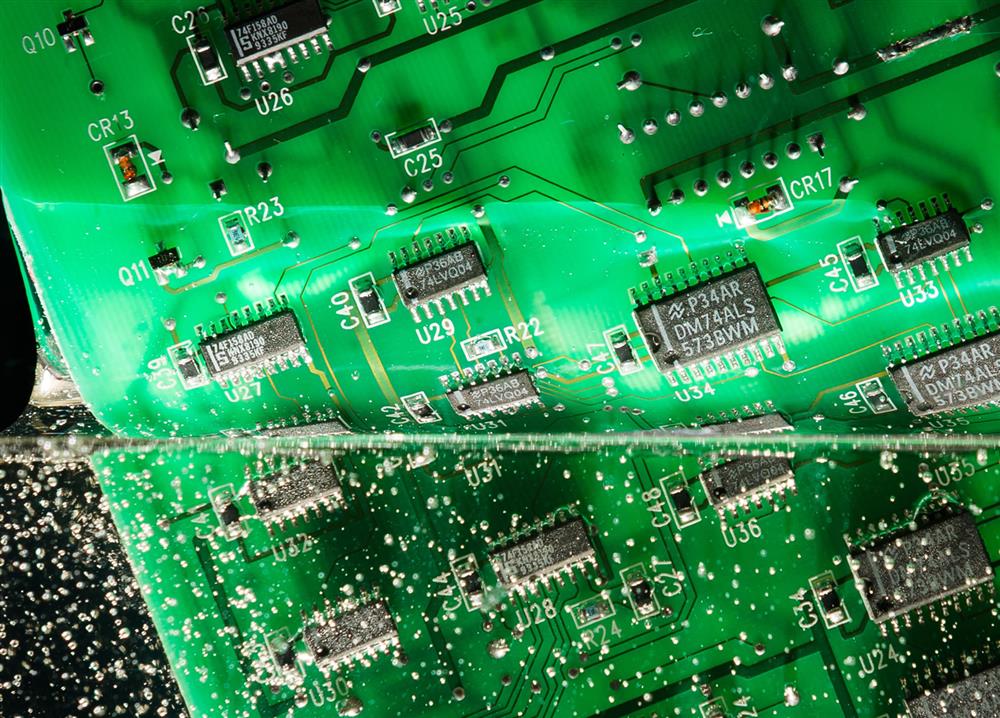

Automotive, Aerospace, General Industry, Electronics and Electronic Components, Logistics and Warehouse are the top industries expected to shift to fully autonomous production in near future.

So what do factories have to do to get started?

Anyone looking for A Fully Autonomous Factory Building Solution will find what they need at Prostech.

In the video above, we can see how a mobile robot from GROBITEC works in the factory without human control. It has the ability to self-locate, memorize the factory map during commissioning and setup, collision-free path planning and can move even heavy to very heavy objects such as cars and planes with the highest precision.

The core of our software platform architecture is the iWMS (Intelligent Warehouse Management System) and the RCS (Robotic Control System). iWMS docks with the upper-level system seamlessly to realize intelligent warehouse management at high efficiency and low costs.

At Prostech, we provide flexible solutions, suitable for many types of manufacturing plants, with a variety of robot sizes and operating systems customized to your requirements. Contact us today to be a pioneer in building a lights-out factory.