The evolution of smart home technology has transformed the way we interact with our living spaces. Devices such as smart thermostats, lighting systems, security cameras, and digital locks have become integral components of modern homes, offering enhanced convenience, security, and energy efficiency. Among these, digital locks stand out by providing keyless entry, remote access, and seamless integration with other smart devices, thereby elevating both security and user experience

Adhesive Solutions for Digital Lock Assembly

Constructing a reliable digital lock necessitates meticulous attention to the adhesives used during assembly. The chosen adhesives must ensure robust bonding, water resistance, aesthetic integrity, and durability under varying environmental conditions.

Digital Lock Assembly Adhesives:

High-Strength Adhesives and Tapes: Utilizing high-strength adhesives or double-sided tapes is essential for securely bonding various components of the digital lock. These adhesives must provide strong adhesion to materials like metals, plastics, and glass, ensuring the lock’s structural integrity.

Sealing Solutions: Effective sealing is crucial to protect internal components from moisture, dust, and other environmental factors. Adhesives with excellent sealing properties contribute to the lock’s longevity and reliable performance.

Key Requirements:

Strong Adhesion: The adhesive must offer robust bonding to prevent component detachment during operation.

Waterproofing: Water-resistant adhesives are vital to safeguard the lock’s internal electronics from moisture damage, especially in outdoor installations.

Aesthetic Preservation: The adhesive should not interfere with the lock’s design, maintaining a sleek and professional appearance.

Environmental Resilience: Adhesives must withstand temperature fluctuations, humidity, and thermal shocks to ensure consistent performance.

Prostech’s Solutions for Digital Lock Assembly:

Prostech offers advanced adhesive solutions designed to meet the demanding requirements of digital lock assembly. Our range of high-performance adhesives provides excellent bonding strength across various materials, including metals, engineering composites, thermoplastics (PMMA, ABS, PA66, and PC), and glass. These adhesives are formulated to ensure:

Superior resistance to severe thermal shock, maintaining structural integrity even in extreme temperature variations.

Excellent aging resistance and low moisture absorption, ensuring long-term durability.

Solvent-free composition, making them environmentally friendly and safe for application.

Compatibility with materials of different coefficients of thermal expansion, preventing stress-induced failures.

Suggested Product:

ITW Performance Polymers Devcon HA1804 Two-component Hybrid & Flexible Adhesive

For more information on Prostech’s industrial adhesive solutions, visit our product page.

Thermal Management for Digital Locks:

Protecting electronic circuits within digital locks is vital for ensuring functionality and extending the device’s lifespan. Effective thermal management prevents overheating, which can lead to component failure.

Importance of Thermal Management:

Component Protection: Efficient heat dissipation safeguards sensitive electronics from thermal stress.

Performance Stability: Maintaining optimal temperatures ensures consistent operation and reliability.

Extended Lifespan: Proper thermal management contributes to the durability of the lock’s electronic components.

To explore thermal management solutions for electronic circuits, read our detailed solutions on Thermal Management Solutions

Prostech is a trusted provider of thermal management materials for electronic devices. Our comprehensive range of thermal solutions helps ensure the durability and efficiency of electronic components in smart home applications. Explore all our thermal management products here:

View all Thermal Management Products

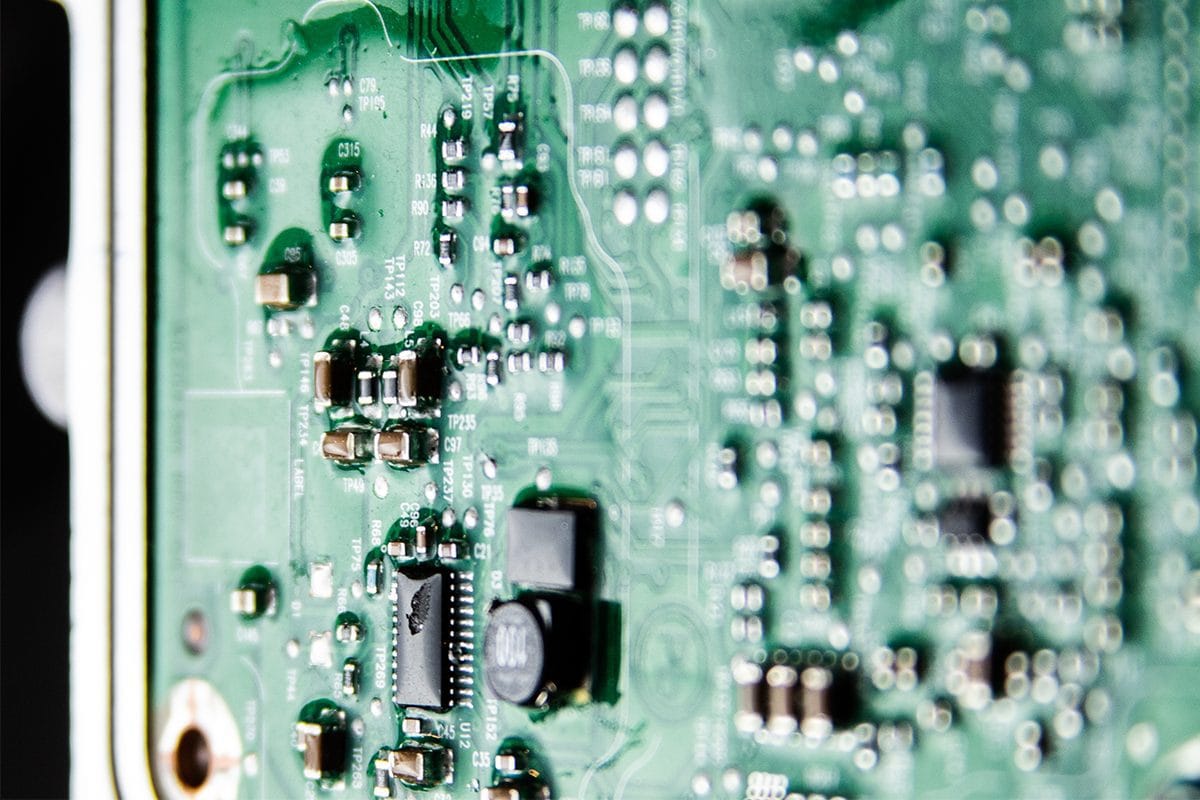

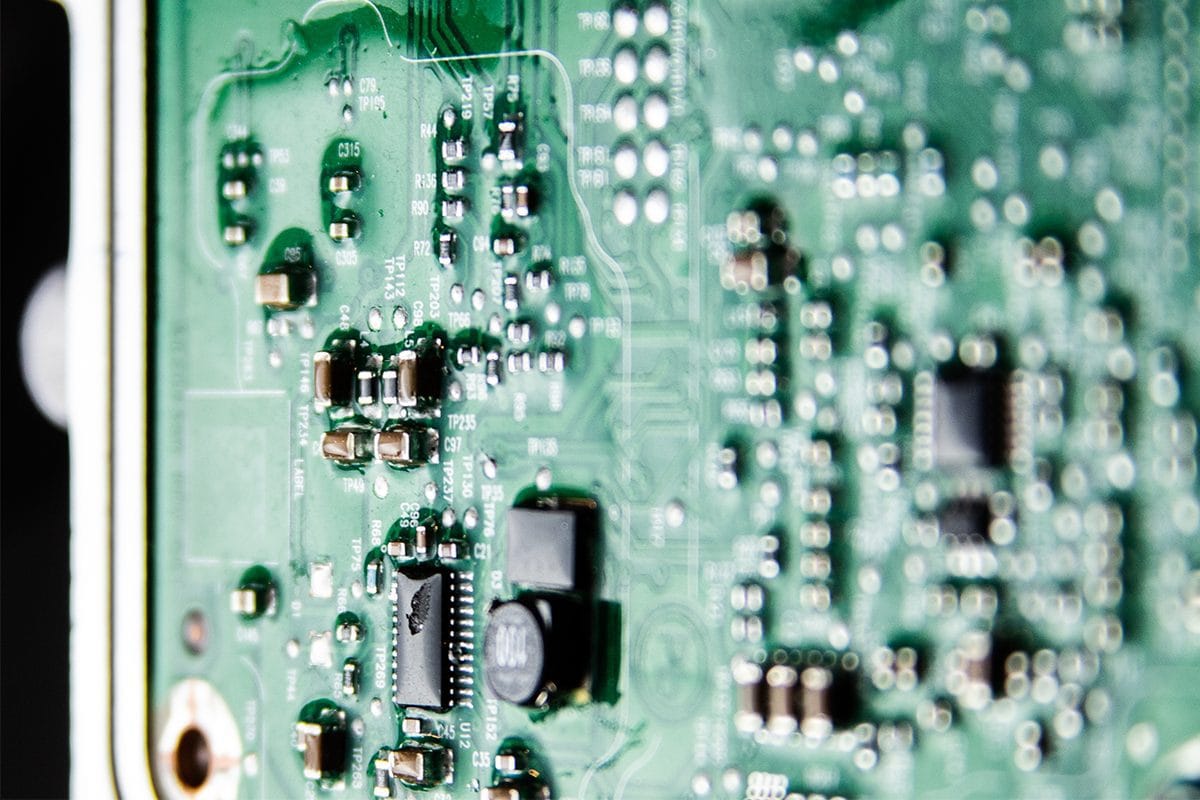

Protective Solutions for Electronic Circuits:

Ensuring the protection of electronic circuits within digital locks is crucial for reliable operation. Various methods are employed to shield these components from environmental factors:

Conformal Coating: This involves applying a thin protective layer over the circuit board, safeguarding against moisture, dust, and chemical contaminants.

Potting: Encapsulating the entire circuit in a solid or gel-like compound provides robust protection against vibration, shock, and harsh environmental conditions.

Low-Pressure Molding: This technique uses low-pressure injection molding to create a protective shell around electronic components, offering mechanical support and environmental protection.

For an in-depth understanding of these protective methods, please contact us for consultation!

Contact Prostech for Specialized Solutions

Prostech specializes in providing tailored solutions for the manufacturing of electronics, home appliances, and smart home devices. Our services include product selection consultation, compatibility testing in our laboratory, and global delivery support. With extensive experience in material supply, we are committed to meeting the high standards of our clients. Contact Prostech to discover the most suitable products for your manufacturing needs.