What is UV adhesive?

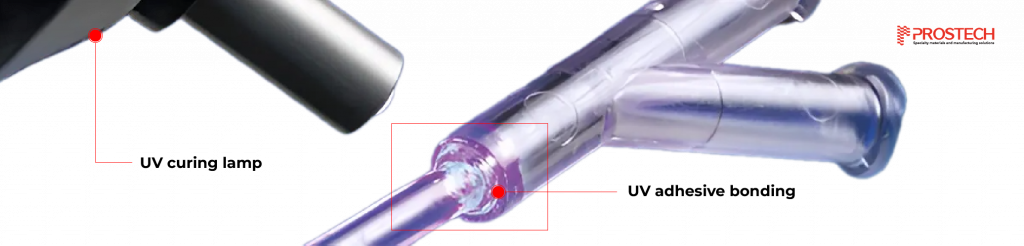

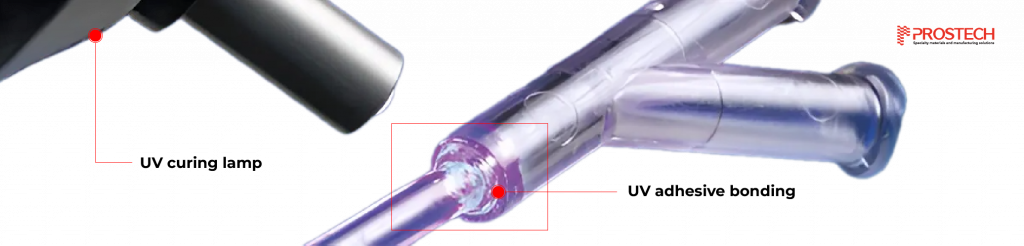

UV adhesive (also known as UV resin or UV activated glue) is a special type of adhesive that cures or hardens when exposed to light of the appropriate wavelength. When polymerization occurs, the UV adhesive becomes hard and creates a strong bond between the surfaces.

To use UV adhesive effectively, a UV light source is necessary to activate the polymerization process. Typically, devices such as UV lamps or UV bulbs are used to provide the necessary UV light.

One of the strengths of UV adhesive is its fast curing time, helping to increase productivity and efficiency in the bonding process. In addition, UV adhesive can also create strong bonds, withstand pressure, and resist environmental factors such as high temperatures, chemicals, and ultraviolet rays.

Those characteristics allow UV adhesive to be used in a variety of bonding, fixing, and fast curing applications. UV adhesive can bond materials such as ceramics, stone, wood, plastic, metal, and even different types of material which cannot be bonded with regular adhesive.

Read more: UV Adhesive – A Comprehensive Overview

Applications of UV adhesive in electronics industry

UV glue is also widely used in the electronics industry with many important applications. Here are some examples of the use of UV glue in the electronics industry:

Read more: Applications of UV Adhesive in Automotive Industry

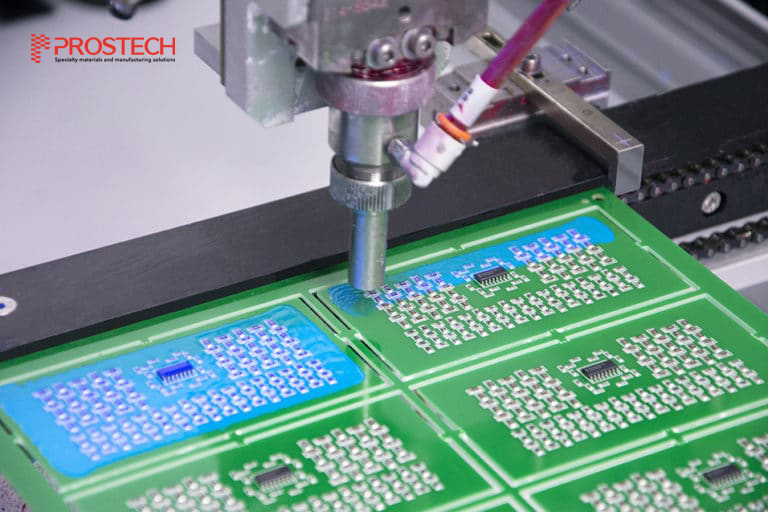

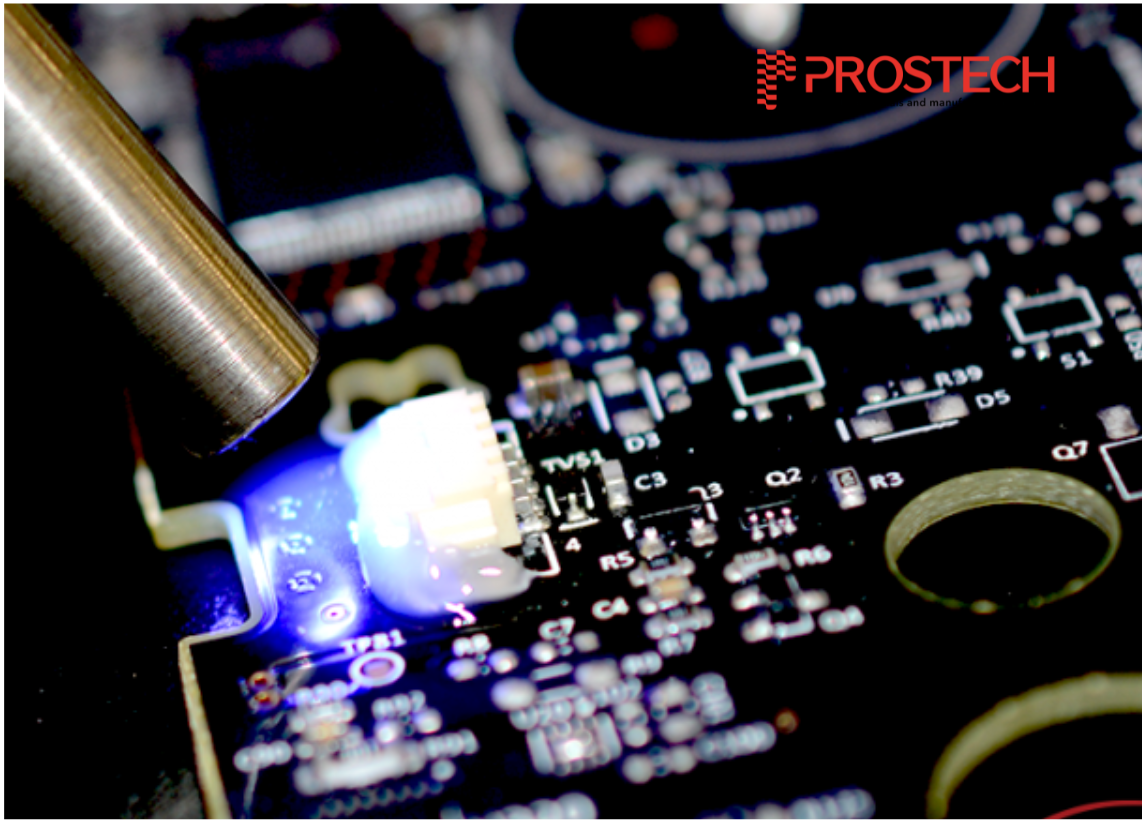

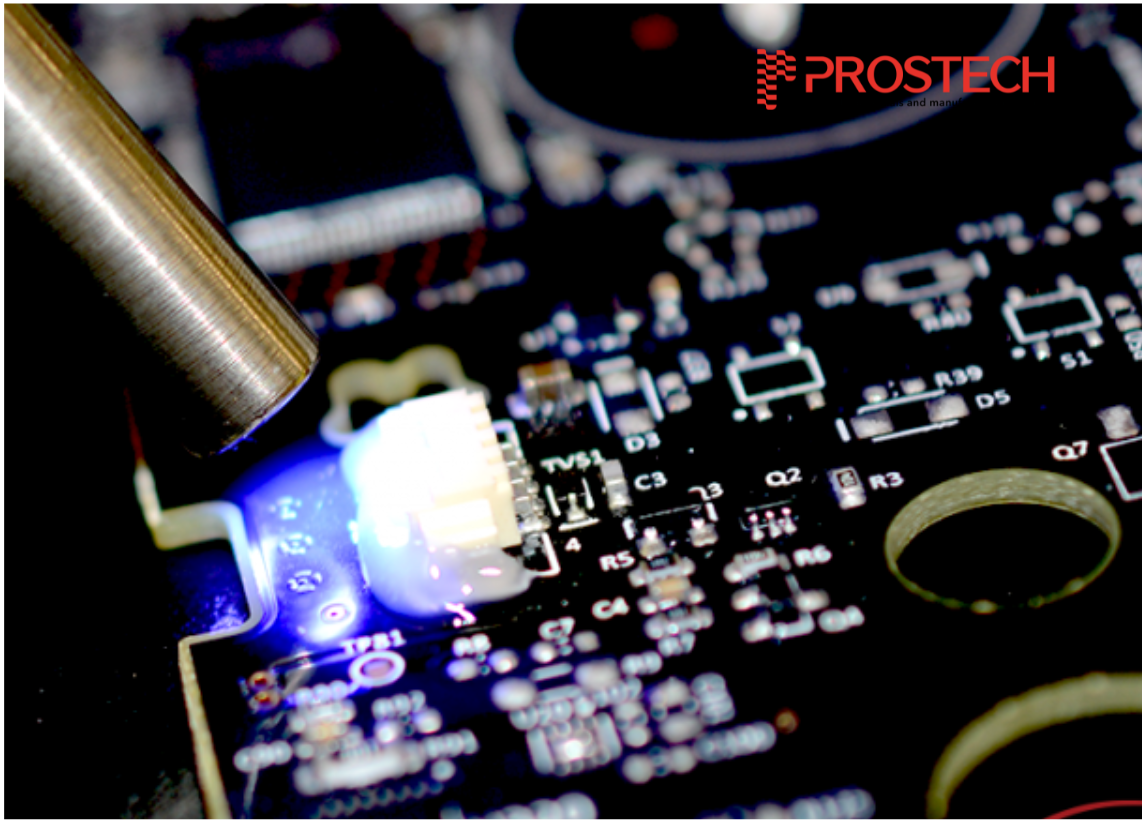

Conformal coating of printed circuit boards (PCB)

UV adhesive has emerged as a preferred choice for conformal coating due to its fast curing time, excellent adhesion properties, and ability to provide a uniform coating even on complex PCB geometries. UV adhesive helps create a tough and water-resistant bond, while also improving the durability and stability of the PCB.

Bonding and sealing of displays

UV glue is used to bond LCD, OLED or touch screens to electronic devices such as mobile phones, tablets, and other electronic screens. UV adhesive, particularly formulated for optically clear applications, offers exceptional clarity, low shrinkage, and high bond strength, ensuring seamless integration and long-lasting performance of displays. Manufacturers can achieve superior aesthetics and durability in display devices.

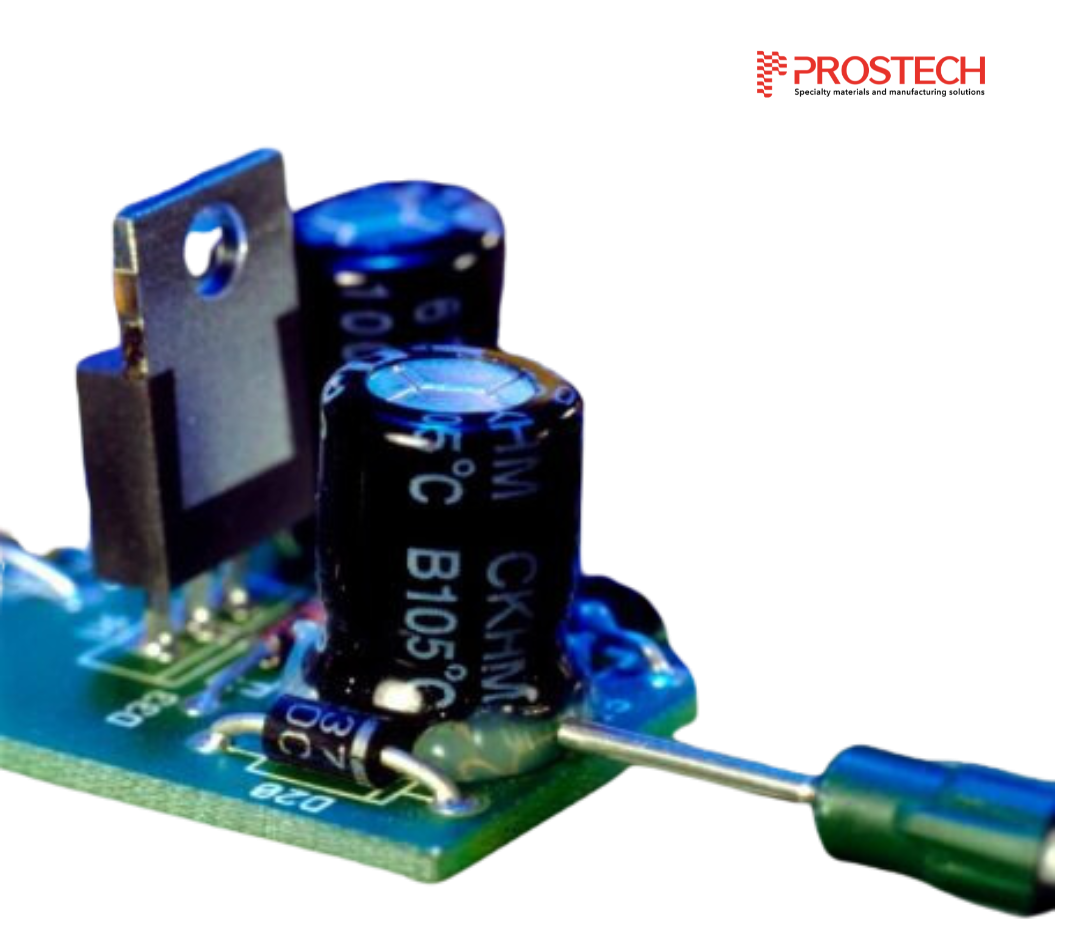

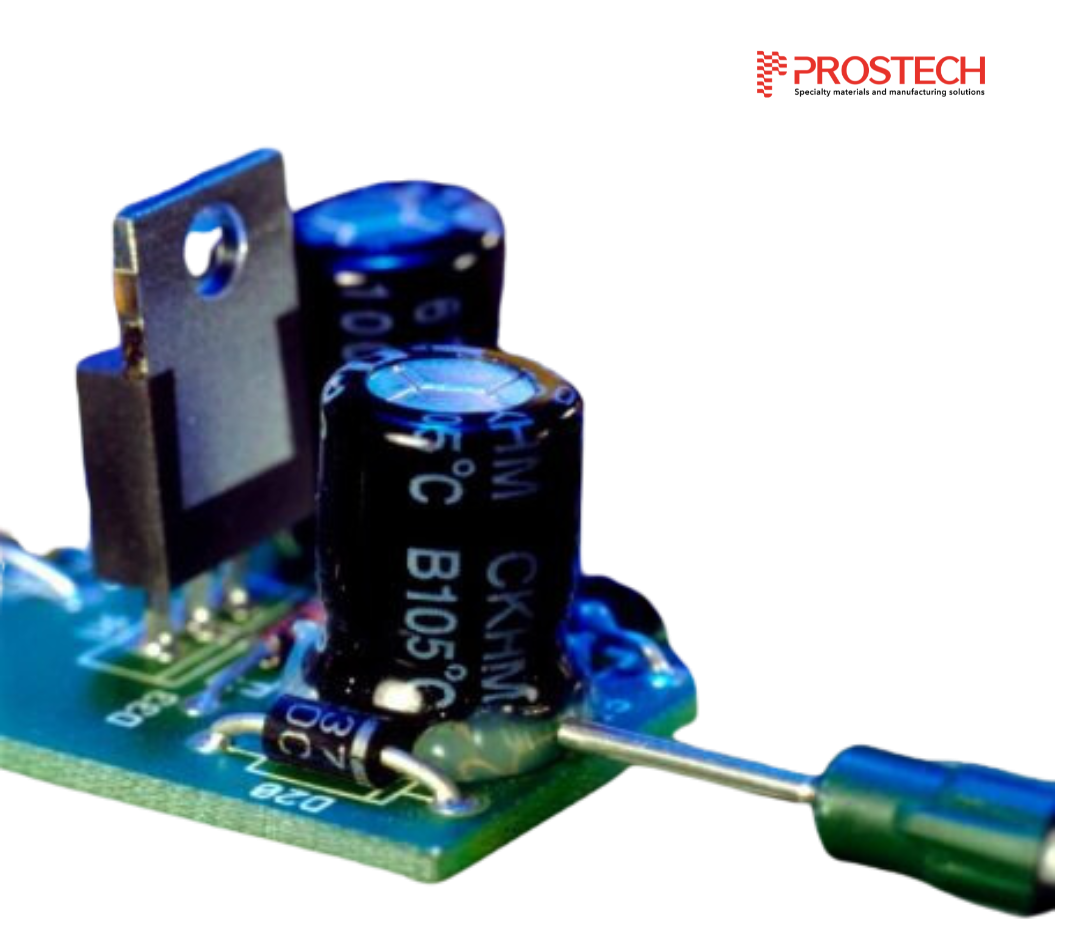

Bonding electronics components

UV adhesive has emerged as a versatile solution for attaching small components such as chips, diodes, sensors, and processors to the board. UV adhesive offers rapid curing, provides a strong and reliable bond, while minimizing thermal impact on sensitive components.

Wire tacking, die and pin attachments

UV adhesive is well-suited for the applications where precise and secure connections are essential. It offers rapid curing and strong adhesion properties that ensure robust bonding in various scenarios. Moreover, its ability to bond dissimilar materials, such as metal, plastic, and ceramic, makes UV adhesive an indispensable tool in electronics manufacturing.

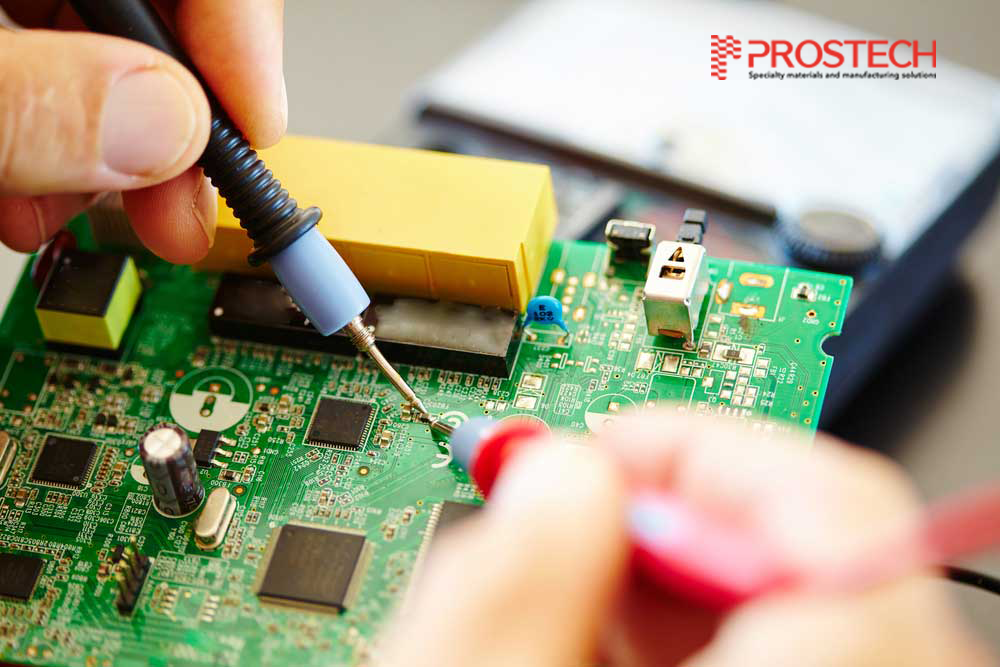

Repair and maintenance

UV glue is used in the repair and maintenance of electronic devices. It can be used to repair cracks, reattach damaged components and protect damaged areas on the PCB.

Solutions for electronics industry

Can UV adhesive be used to protect electronic components from high temperature impact?

UV glue is resistant to high temperatures; however, the heat resistance of UV glue may vary depending on the specific glue type and manufacturer.

There are UV glues specifically designed to withstand high temperatures, which can withstand 150°C (302°F) or more. These types of glues are often used in applications that require high heat resistance such as in the automotive industry, industrial electronics, or electronic devices with high operating temperatures.

However, when using UV glue to protect electronic components from high temperature impact, other factors need to be considered such as time of exposure to high temperature, temperature variation and surrounding environment.

If the component or surface to which UV adhesive is applied has special high temperature requirements, it is necessary to choose a UV glue with high heat resistance properties and comply with the manufacturer’s instructions and specifications.

So, before using UV glue to protect electronic components from high temperature impact, be sure to check the specifications of the specific UV adhesive and ensure that it conforms to the requirements and environmental conditions of the specific application.

___________

Ready to optimize your electronics manufacturing process with UV adhesive solutions? Contact us today for expert consultation!