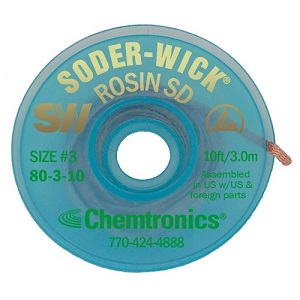

Soder-Wick 80-3-10 offers the state of the art in desoldering technology. Soder-Wick is designed for today’s heat sensitive electronic components using lighter mass, pure copper braid construction that allows for better thermal conductivity, even at low temperatures. Soder-Wick responds faster than conventional desoldering braids thereby minimizing overheating and preventing PCB damage. A full range of sizes and flux types are available, including Rosin, No Clean, unfluxed and a high temperature Lead-Free version. Whatever the requirement, Soder-Wick has the answer.

FEATURES:

- Requires little or no post solder cleaning

- No corrosive residues

- Optimized construction for faster wicking and heat transfer

- Halide free

- Minimizes the risk of heat damage to components and circuit boards

TYPICAL APPLICATIONS: Soder-Wick 80-3-10 desoldering braid safely removes solder from:

- Thru-hole Components

- SMT Pads and BGA Pads

- Micro Circuits

- Terminals

- Lugs and Posts

- Identification Script

| Flux Types | Rosin Grade WW, Type “R” Patented No Clean High Temperature No Clean |

| Specifications | ANSI/IPC J STD-004 MIL-F-14256 F |

| No Clean Flux Spec | MIL-STD-883B Bellcore TR-NWT-000078 ANSI/IPC J SF818 |

| Shelflife | 2 years |