Product description

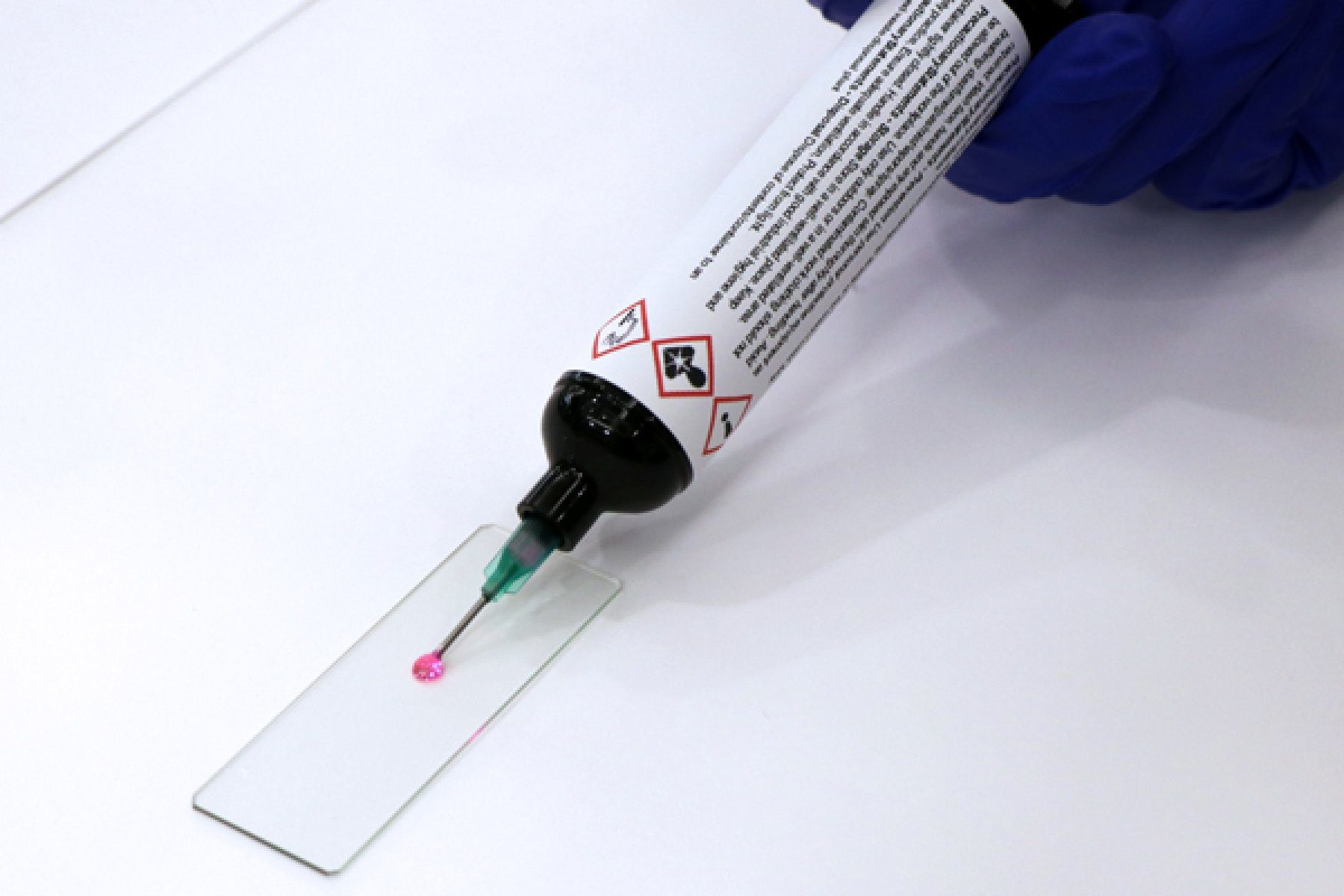

Dymax SpeedMask® 758-H maskant is formulated for UV/Visible and LED light curing to provide good surface protection during acid stripping, chemical milling/etching, plating, anodizing, and aggressive grit-blasting operations. It aids in the manufacture, overhaul, repair, and rework of turbine engine blades, vanes, and other turbine components. It is a Multi-Cure® mask specially formulated to cure with heat in applications where shadow areas exist. This 100% organic resin cures quickly and is peelable, while any internal material can be removed by incineration in an air furnace at a minimum temperature of 650°C [1200°F] leaving a residue-free surface with minimal ash from combustion of the maskant. The removal of the cured maskant on the surface of the component can be aided with the use of a hand tool (plastic, anti-static or metal), heat aided to localize area, an ultrasonic bath, dry ice blast or embrittlement, water jet blast, incineration, when applicable or automated grippers. Please reach out to Dymax Application Engineering for details on these removal options. SpeedMask resins contain no nonreactive solvents and cure upon exposure to light. Their ability to cure in seconds enables faster processing, greater output, and lower processing costs. When cured with Dymax light-curing spot lamps, focused-beam lamps, or flood lamps, they deliver optimum speed and performance for many masking applications. Dymax lamps offer the ideal balance of UV and visible light for the fastest, deepest cures. This product is in full compliance with RoHS directives 2015/863/EU.

Features of Dymax SpeedMask® 758-H maskant

- UV/Visible and LED (405 nm) Light Cure Secondary Heat-Cure Capability

- Low Shrinkage

- Resistant to Nitric, Sulfuric, and Hydrochloric Acid

- Trimmable After Cure Sprayable

- Peelable or Incineration Removal

Applications of Dymax SpeedMask® 758-H maskant

- Acid Stripping Plating Baths

- Aggressive Grit Blasting

- Plating Baths

Prostech offers specialty materials (adhesives, tapes, thermal interface materials, insulating materials, sealants, PCB protection materials, …) along with manufacturing solutions. We proudly serve a wide range of industries and are an authorized distributor for leading global manufacturers of industrial materials and equipment. Our product range is designed to deliver customized solutions that address each customer’s unique needs. With years of experience and a successful project history, we are confident in our ability to provide comprehensive material solutions. These solutions effectively tackle the challenges manufacturers face. To explore our full product catalog, simply click here. Our dedicated team is ready to assist with: Moreover, Prostech ensures the safe and accurate global delivery of all materials, including “dangerous goods”, in compliance with legal regulations. For personalized technical support or to receive a quotation, please contact us today.About Prostech

UNCURED PROPERTIES * | ||

Property | Value | Test Method |

Solvent Content | No Nonreactive Solvents | N/A |

Chemical Class | Acrylated Urethane | N/A |

Appearance | Red Opaque Gel | N/A |

Soluble in | Organic Solvents | N/A |

Density, g/ml | 1.08 | ASTM D1875 |

Viscosity, cP | 11,500 (nominal) | DSTM 502‡ |

Shelf Life at Recommended Conditions from Date of Manufacture |

7 months |

N/A |

CURED MECHANICAL PROPERTIES * | ||

Property | Value | Test Method |

Durometer Hardness | A80 | ASTM D2240 |

Tensile at Break, MPa [psi] | 3.4 [500] | ASTM D638 |

Elongation at Break, % | 140 | ASTM D638 |

Modulus of Elasticity, MPa [psi] | 2.3 [330] | ASTM D638 |

Glass Transition Tg, ˚C | 26 | ASTM D5418 |

OTHER CURED PROPERTIES * | ||

Property | Value | Test Method |

Boiling Water Absorption, % (2 hr) | 1.6 | ASTM D570 |

Water Absorption, % (25°C, 24 h) | 0.5 | ASTM D570 |

Linear Shrinkage, % | 1.7 | ASTM D2566 |