Product description

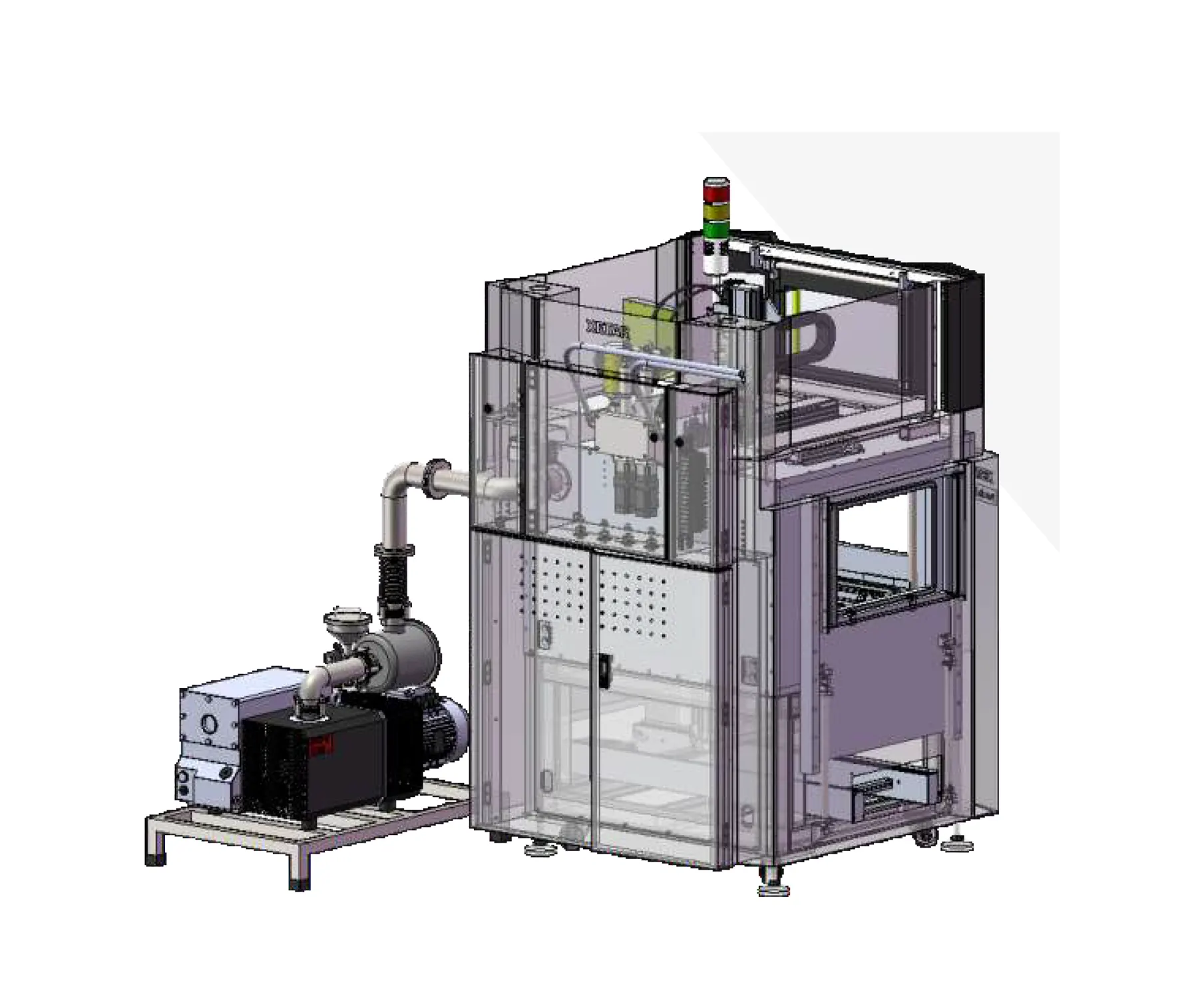

The PottBull-VL vacuum potting system is a specialized solution for batch vacuum glue injection. The entire potting process takes place in a vacuum environment to prevent air and moisture from entering the product during potting. Simultaneously, the system eliminates air bubbles within product gaps, ensuring complete material filling of the product cavity.

Features of PottBull-VL Online Vacuum Dispensing System

- Vacuum Environment: Prevents air and moisture ingress, eliminating voids and defects.

- Automated Material Supply System: Draws raw materials into the stock barrel via vacuum while performing synchronous stirring, de-aeration, temperature control, hydraulic control, and material circulation.

- Flexible Glue Injection System: Supports single or multiple glue injection nozzles, combined with a triaxial movement system to accurately dispense glue into the product.

- High Production Efficiency: A high-performance vacuum pump and multiple glue injection nozzles enable simultaneous processing of multiple products, reducing production time.

- Advanced Control System: Features a multi-touch control panel based on Beckhoff PC+, allowing direct operation, glue injection program configuration, and high system upgradability and flexibility.

Applications of PottBull-VL Online Vacuum Dispensing System

The PottBull-VL system is ideal for batch vacuum glue injection processes, particularly in scenarios that require:

- Air bubble removal from product gaps to ensure complete material filling.

- Prevention of air and moisture ingress during the potting process.

- Automated glue injection control, including stirring, de-aeration, temperature regulation, and hydraulic management.

- Increased production efficiency through high-performance vacuum pumps and multiple glue injection nozzles for simultaneous multi-product potting.

- Precise positioning using a triaxial movement system to ensure accurate glue dispensing.

- Flexible operation via a multi-touch control interface, enabling programmable glue injection processes and system upgrades.

Prostech offers specialty materials (adhesives, tapes, thermal interface materials, insulating materials, sealants, PCB protection materials, …) along with manufacturing solutions. We proudly serve a wide range of industries and are an authorized distributor for leading global manufacturers of industrial materials and equipment. Our product range is designed to deliver customized solutions that address each customer’s unique needs. With years of experience and a successful project history, we are confident in our ability to provide comprehensive material solutions. These solutions effectively tackle the challenges manufacturers face. To explore our full product catalog, simply click here. Our dedicated team is ready to assist with: Moreover, Prostech ensures the safe and accurate global delivery of all materials, including “dangerous goods”, in compliance with legal regulations. For personalized technical support or to receive a quotation, please contact us today.About Prostech