PRODUCT DESCRIPTION

Dymax Multi-Cure® 6-621-GEL adhesive cures upon exposure to light and is designed for rapid assembling of parts made of metal, glass, ceramic, phenolic, filled polyamide, and other materials. Dymax 6-621-GEL adhesive is specially formulated to cure with heat in applications where shadow areas exist. Dymax Multi- Cure materials contain no nonreactive solvents. Their ability to cure in seconds enables faster processing, greater output, and lower processing costs. When cured with Dymax light-curing spot lamps, focused-beam lamps, or flood lamps, they deliver optimum speed and performance for industrial product assembly. Dymax lamps offer the ideal balance of UV and visible light for the fastest, deepest cures. This product is in full compliance with RoHS directives 2015/863/EU.

FEATURES of Dymax Multi-Cure® 6-621-GEL

- UV/Visible Light Cure Secondary Heat Cure Activator Cure

- Bonds Multiple Substrates

- Hard and Clear Bonds

- Secondary Heat Cure

- Activator Cure

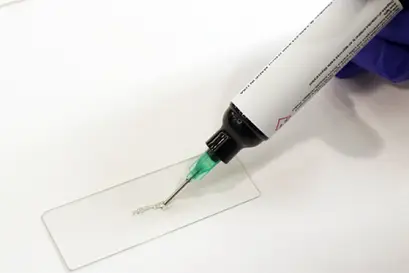

APPLICATIONS of Dymax Multi-Cure® 6-621-GEL

- Metal-to-Glass Bonding

- Coil Winding

- Potting

- Structural Battery Bonding

- Parts Assembly

About Prostech

Prostech offers specialty materials (adhesives, tapes, thermal interface materials, insulating materials, sealants, PCB protection materials, …) along with manufacturing solutions. We proudly serve a wide range of industries and are an authorized distributor for leading global manufacturers of industrial materials and equipment. Our product range is designed to deliver customized solutions that address each customer’s unique needs.

With years of experience and a successful project history, we are confident in our ability to provide comprehensive material solutions. These solutions effectively tackle the challenges manufacturers face. To explore our full product catalog, simply click here. Our dedicated team is ready to assist with:

- Provide quotation, sample, TDS/MSDS, and technical consultation

- Testing sample quality and verifying product compatibility in our laboratory

- Customizing material formulas for special applications

- Adapting product sizes, quantities, and packaging to meet specific needs

- Offering expert advice on suitable equipment and automation processes

- Delivering technical training and on-site support for optimal product use

Moreover, Prostech ensures the safe and accurate global delivery of all materials, including “dangerous goods”, in compliance with legal regulations. For personalized technical support or to receive a quotation, please contact us today.

UNCURED PROPERTIES * | ||

Property | Value | Test Method |

Solvent Content | No Nonreactive Solvents | N/A |

Chemical Class Appearance | Acrylated Urethane Clear Translucent Liquid – Gel | N/A N/A |

Soluble in | Organic Solvents | N/A |

Density, g/ml | 1.08 | N/A |

Viscosity, cP (20 rpm) | 25,000 (nominal) | ASTM D2556 |

Shelf Life @ RT (22°C to 25°C) from Date of Manufacture | 18 months | N/A |

CURED MECHANICAL PROPERTIES * | ||

Property | Value | Test Method |

Durometer Hardness | D80 | ASTM D2240 |

Tensile at Break, MPa [psi] | 28 [4,000] | ASTM D638 |

Elongation at Break, % | 20 | ASTM D638 |

Modulus of Elasticity, MPa [psi] | 730 [106,000] | ASTM D638 |

OTHER CURED PROPERTIES * | ||

Property | Value | Test Method |

Refractive Index (20°C) | 1.51 | ASTM D542 |

Boiling Water Absorption, % (2 h) | 4.1 | ASTM D570 |

Water Absorption, % (25°C, 24 h) | 1.7 | ASTM D570 |

Linear Shrinkage, % | 0.4 | ASTM D2566 |

Glass Transition Tg, ˚C | 75 | ASTM D5418 |

CTEα1, μm/m/˚C | 67 | ASTM E831 |

CTEα2, μm/m/˚C | 228 | ASTM E831 |

DISPENSE EQUIPMENT RECOMMENDATIONS * | |||

Application | Manual | Semi-Automated | Fully Automated |

Dots/Beads | SD-100 | Model 400 Valve | eco-PEN450 |

ADHESION | |

Substrate | Recommendation |

ABS acrylonitrile-butadiene-styrene | X |

EP epoxy, FR4 Circuit Board | X |

PA polyamide | X |

PC polycarbonate | o |

PEI polyetherimide PET poly(ethylene terephthalate) | o o |

Phenolic Plastic | X |

PI polyimide | o |

PU polyurethane | o |

PVC poly(vinyl chloride) | o |

CER ceramic | X |

AL aluminum CU copper | X |

GL borosilicate, quartz, mica | X |

CRS cold rolled steel | X |

SS stainless steel | X |