Choosing the best methods for assembly is always a difficult puzzle to solve. Besides considering the bonding materials, and working conditions of the final product, we also need to think about the best bonding method with suitable costs and the highest performance technique. When it comes to metal-metal bonding, there are some options to choose from such as: welding, mechanical fastening (such as bolts, nuts, rivets, screws,..), and tapes or adhesives.

There are advantages and disadvantages to each method, it depends on your workflow and over-cost to make a decision on which one is the best choice.

Common issues when bonding metal to metal by traditional methods

For metal-to-metal connections, engineers are trying to solve the disadvantages to achieve stronger and more durable connections. Common undesirable phenomenas are mainly related to:

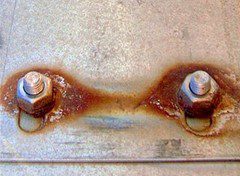

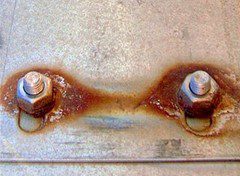

- Galvanic corrosion at the direct metal contact positions (bolt position or weld spot).

- Warping caused by coefficient of thermal expansion mismatch between different metals.

- Uneven stress distribution especially on designs which require bearing capacity.

- Lack of aesthetics due to surface irregularities or poor welds.

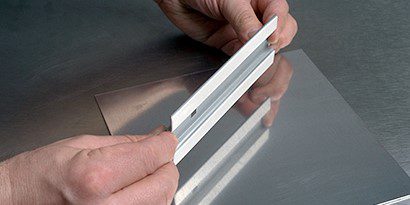

Faster assemble with adhesive

Adhesives and tapes can serve a wide range of metals, bear in mind that removed fasteners and welding leave marks or holes on the surface while tape does not. Considering under high or low temperatures and the aesthetic of appearance, tapes and adhesives are more flexible, faster and offer various chemical bases to prefer. Furthermore, all chemical resistance data are now published by adhesive markers, so it is easy for you to choose the right adhesive for bonding metal in your application and predict costs.

Which one is the best?

When choosing methods you should pay attention to your assembly process. Does your workflow suitable for a new solution or you will change the entire workflow for a new solution?

Weldings will require trained workers and destructive weld inspections for your quality process. Even though you can use an automated system, it will be a costly solution for you.

Mechanical fastening might require inventory management because you have more tools and machines. Also, you must to implement the QC process and might have to consider about final appearance of the product. Sometimes, mechanical fastening need thread lock strength suppliers.

Adhesives and tapes require surface preparation, which might add more steps to your process. However, it is hard to deny the quickness and simplicity of adhesives and tapes.

Prostech with our experienced experts are willing to research with you from the beginning. With thorough understandings about your application, we can provide you with the most suitable solution.