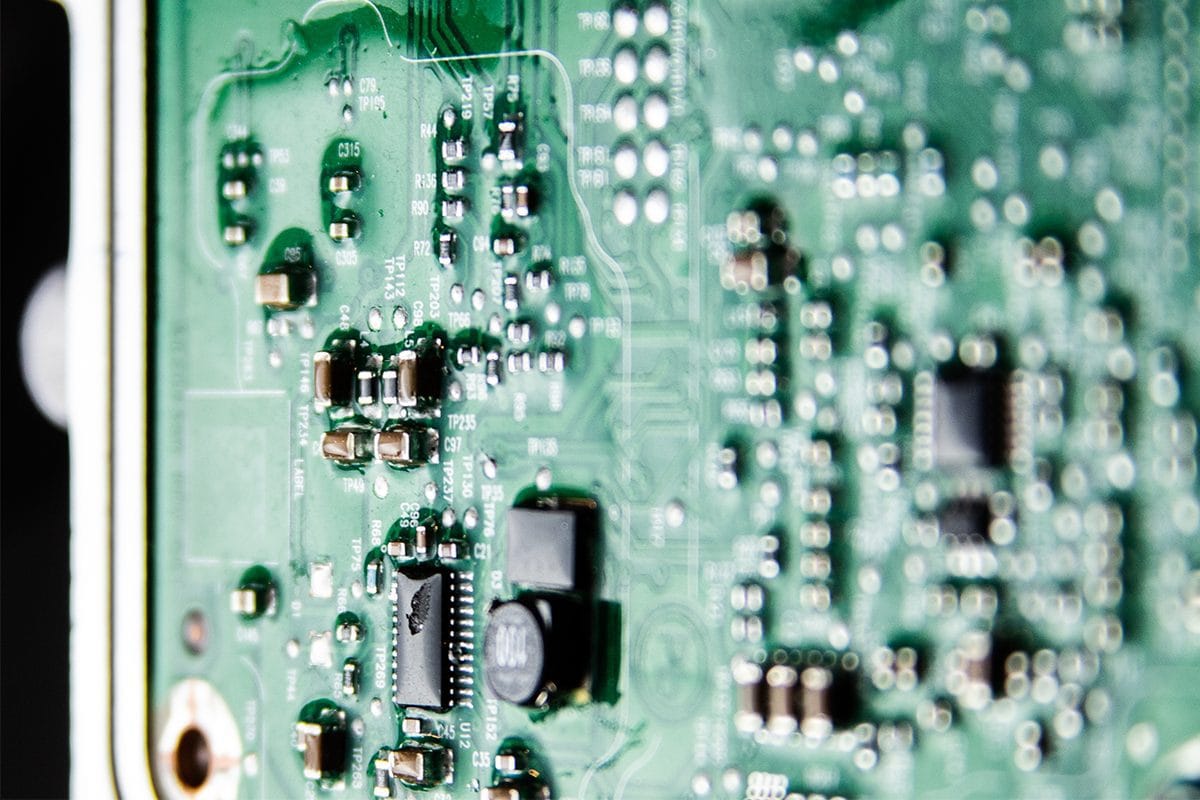

Underfill

Underfills can be used to help reinforce electronic components and minimize stress. They also offer excellent protection of solder joints during thermal cycling, provide reliability against stress

Popular types of underfill

- Underfill CSP

- Underfill BGA

- Underfill WLCSP

- Underfill LGA

- Partial underfill

Materials characteristics for underfill:

- Fast cure

- Good flowability

- High reliability

- Good re-workability

- Excellent SIR performance

Main benefits:

- Improve reliability performance

- Enhancing mechanical performance

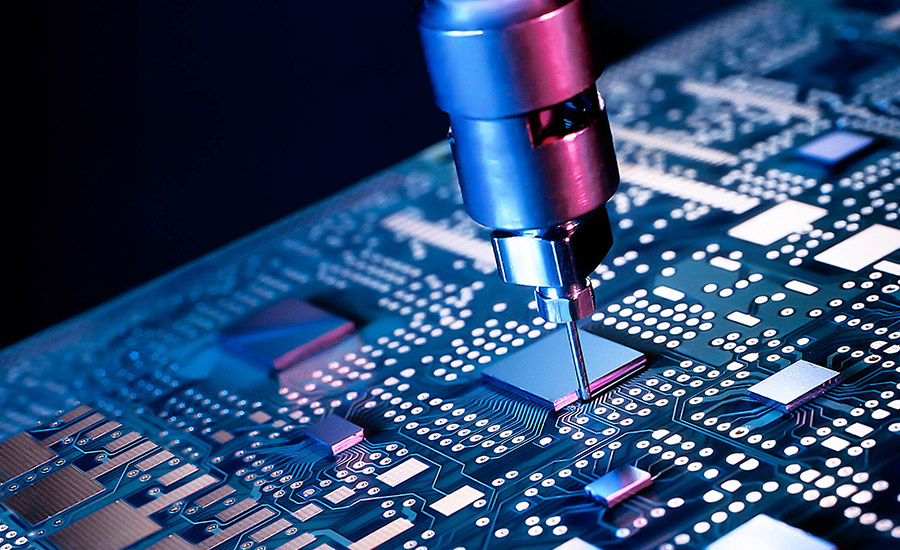

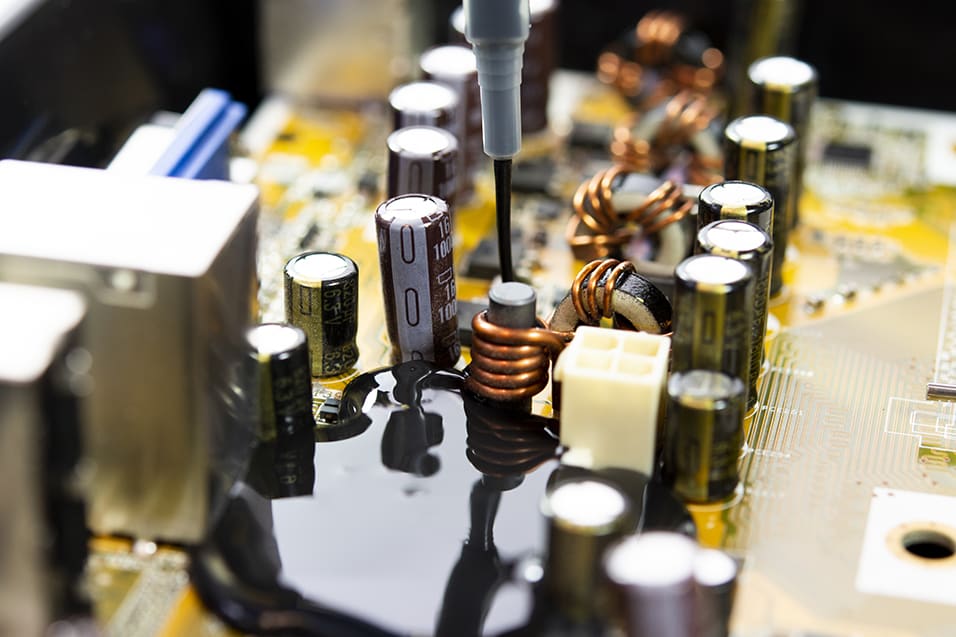

Encapsulation

Encapsulation is a method to place on or around circuit boards and components to provide protection against particles, heat, moisture, and other external pressures.

PCB encapsulation solutions include epoxy, silicone, urethane, and acrylic chemistries that provide manufacturing flexibility across applications.

Typical types of encapsulation:

- Flip-chip

- CSP

- BGA

Materials characteristics:

- Highly flowable

- Excellent jet dispensing performance

- Precise rheology control to meet specified flow requirement

- Precise thixotropic for dot shape control

- UV detectable

- Fast cure and dual curing mechanism for ultimate versatility

- High SIR after 85C/85RH conditioning (1wk)

- High bias voltage

- Suitable for harsh environments

- Survive lead-free reflow

Main benefits:

- Better reliability and mechanical performance

- Moisture & heat resistance and stable electrical performance

For more information on how to choose materials for underfill and encapsulation applications, contact us: