Two of the most prominent advanced technologies in cooling for data centers are immersion cooling and direct-to-chip (D2C) cooling. Each comes with distinct characteristics, advantages, and trade-offs. In this article, we’ll break down how they work, compare their performance, and explore why direct-to-chip cooling is increasingly becoming the preferred choice for hyperscale data centers.

What is Immersion Cooling?

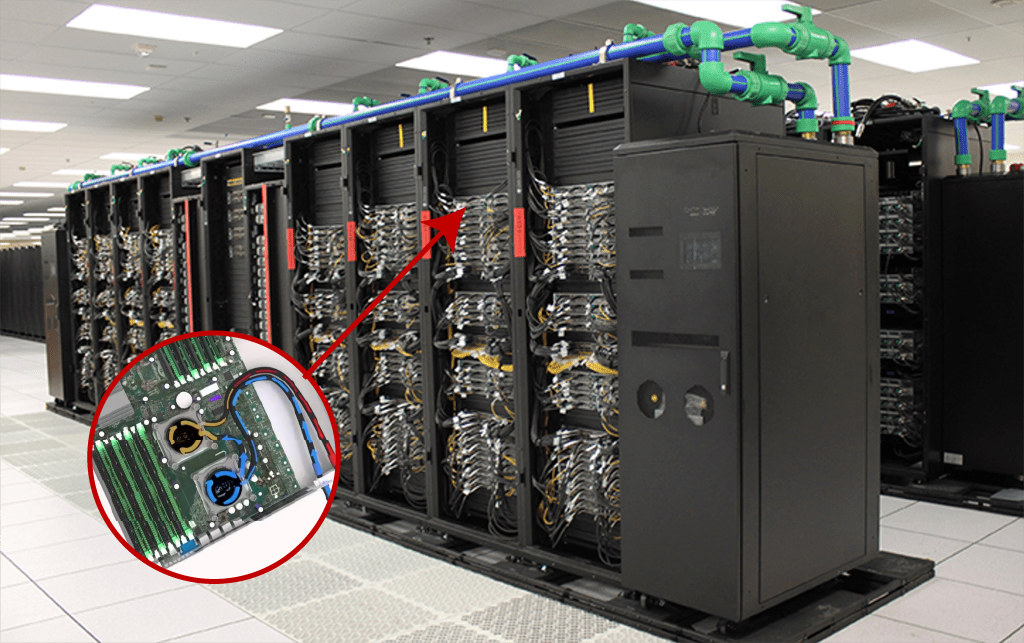

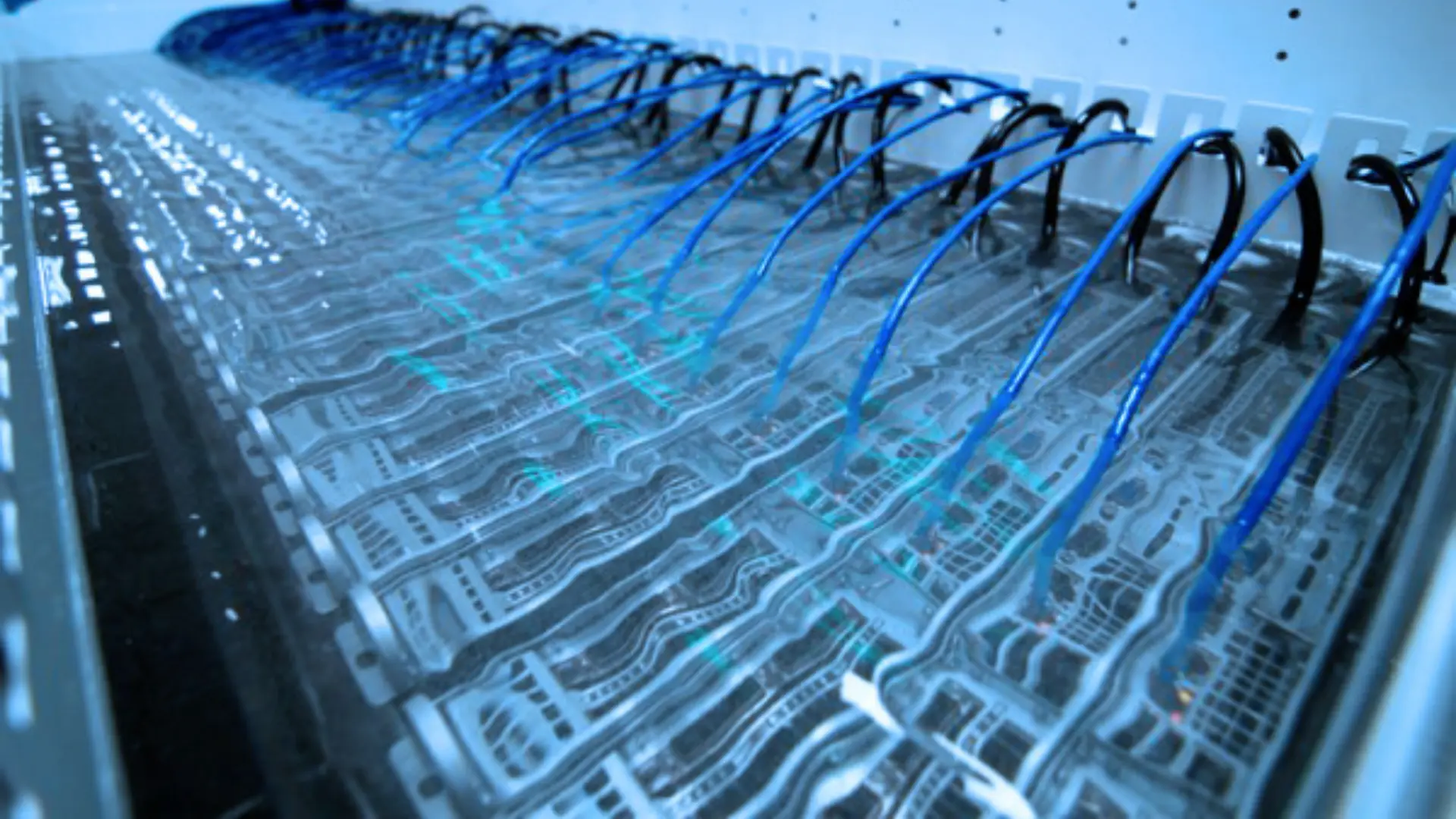

Immersion cooling is a thermal management method where entire servers are submerged in a non-conductive, dielectric liquid. Heat is transferred directly from the electronic components into the coolant. Due to the temperature gradient, the warmer, less dense liquid rises and is replaced by cooler liquid from below — a process known as natural convection. This process helps remove the heat from the system.

Immersion cooling for data centers generally falls into two main types, based on how the electronic components interact with the coolant:

- Single-phase immersion cooling (e.g., mineral oils, synthetic hydrocarbons): involves using coolants to exchange heat without any phase changes. This method is safer because of this as this means there is no gas /vapor produced by the cooling system, hence, protecting the system from explosion due to excessive pressure.

- Two-phase immersion cooling (e.g., engineered fluorocarbons): This cooling technique uses coolants to exchange heat when liquid-vapor phase change occurs. As the coolant reaches its ultra-low boiling point, the vapor bubbles rise to the top and enter a gaseous state. After evaporating, the vapor comes in contact with a condenser that returns it back to its liquid state. The fluids flow back into the bath to renew the cycle.

Pros:

- Exceptional heat removal capacity

- Compact server design possibilities

- Reduces cooling-related energy consumption dramatically

Cons:

- Higher initial infrastructure cost

- Requires specialized equipment and maintenance procedures

- Potential compatibility and standardization issues

What is Direct-to-Chip (D2C) Cooling?

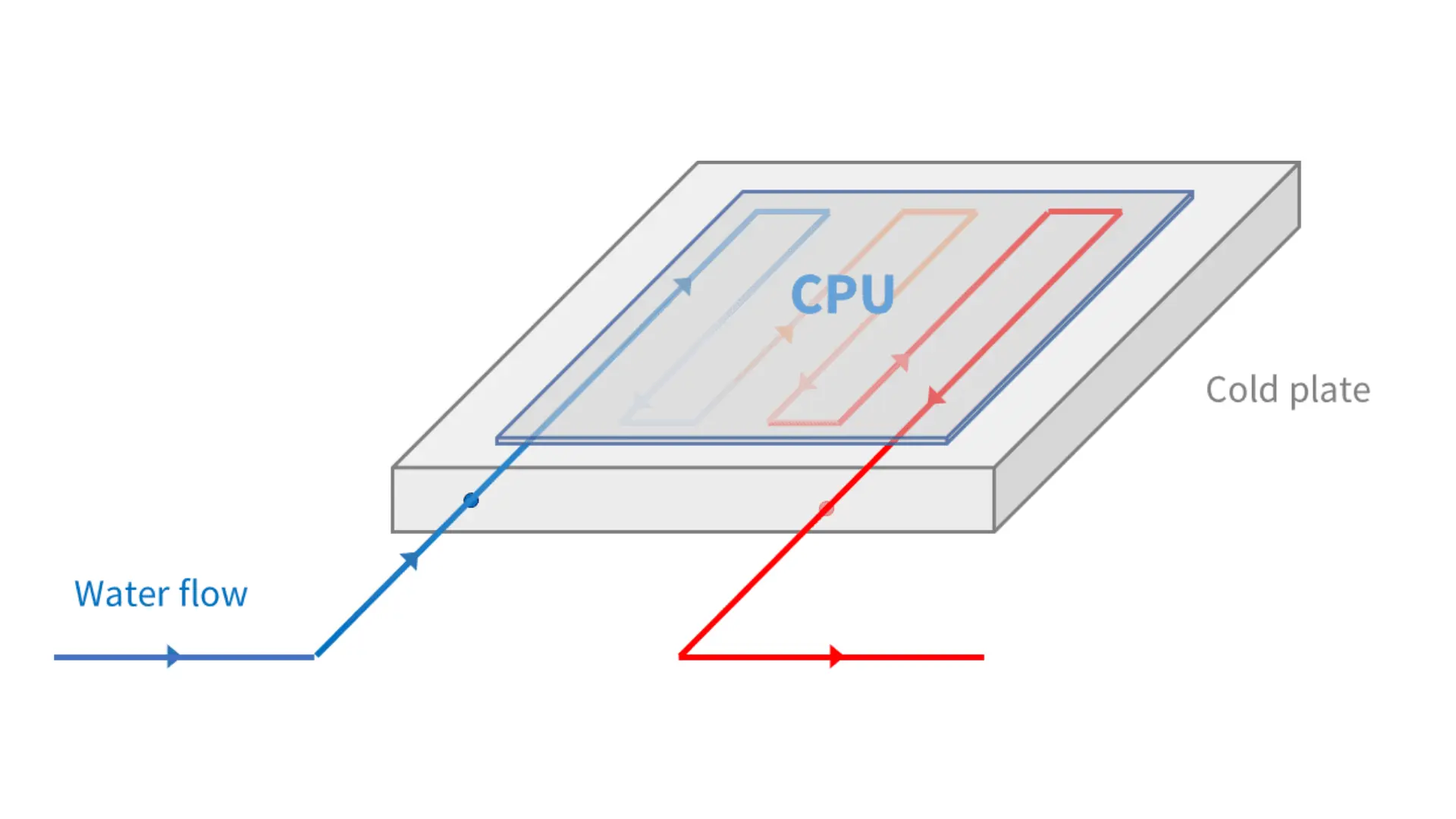

Direct-to-chip cooling for data centers involves placing cold plates directly on heat-generating components such as CPUs or GPUs. Coolant is pumped through microchannels in these plates to absorb and carry away the heat.

There are two main types of coolants used in Direct-to-Chip (D2C) cooling systems:

- Water-based (with corrosion inhibitors): These are deionized water solutions blended with specific corrosion inhibitors. They are commonly used for their excellent heat transfer properties and low cost. However, water alone is highly corrosive, so inhibitors such as silicates, phosphates, or organic acids are required to form a protective film on metal surfaces.

- PG-based coolants: These fluids are particularly suitable for data center environments because they maintain long service life under high thermal stress, protect against corrosion in mixed-metal systems (aluminum, copper, steel). Among these, OAT (Organic Acid Technology) formulations are preferred due to their slow consumption rate and self-regenerating protective layer, which reduces maintenance needs and extends the fluid change intervals.

Pros:

- High cooling efficiency with targeted component-level control

- Easier integration with existing infrastructure

- Lower fluid volume compared to immersion systems

Cons:

- Limited to specific components (CPU/GPU); may not address other heat sources

- Requires precise engineering for each chip layout

|

Feature |

Immersion Cooling |

Direct-to-Chip (D2C) Cooling |

|

Cost |

High upfront cost |

Moderate, scalable cost |

|

Maintenance |

Specialized training required |

More manageable & familiar |

|

Cooling Efficiency |

Very high |

High |

|

Fluid Management |

Large fluid volume |

Low fluid volume, localized flow |

|

Scalability |

Challenging for retrofits |

Ideal for gradual scaling |

|

Component Access |

Difficult |

Easy access for upgrades/repairs |

|

Environmental Impact |

Dependent on fluid type |

Lower, especially with PG-based fluids |

Comparison: Immersion Cooling vs. Direct-to-Chip Cooling

Why Direct-to-Chip Cooling is the Future for Hyperscale Data Centers

As hyperscale data centers grow in size and processing power, direct-to-chip cooling offers a sweet spot between performance, maintainability, and operational scalability. Unlike immersion systems, which require a complete overhaul of infrastructure, D2C can be integrated with existing air-cooled systems, creating hybrid environments that transition smoothly into liquid cooling.

Moreover, D2C supports more granular thermal control at the component level, enabling higher rack densities and better energy efficiency. It also provides a practical pathway for data centers to meet sustainability goals without the complexity of full immersion systems.

Success Case: How PG-Based Coolants Support D2C Cooling for Data Centers

One of the key enablers of successful D2C deployments is the coolant. OAT PG-25, a propylene glycol-based fluid with Organic Acid Technology (OAT), is specifically formulated for electronics cooling. It offers:

- Superior thermal conductivity for effective heat transfer

- Long-term corrosion protection across metals used in cold plates and pipes

- Low toxicity and low environmental impact compared to many immersion fluids

- Operational stability, even under variable load conditions

Unlike traditional water-based coolants—which often rely on inorganic corrosion inhibitors that deplete over time and are prone to bio-growth—OAT PG-25 is premixed and ready to use, requiring no dilution. In fact, many end users now flush their systems with PG-25 following the initial DI water rinse to ensure optimal system performance.

Most importantly, Recochem’s OAT PG-25 is tested, recommended, and actively used by leading chip, server, and CDU manufacturers, making it a trusted solution in modern hyperscale data center deployments.

Prostech is the authorized distributor of Recochem’s products. Backed by deep technical knowledge and close collaboration with leading manufacturers, we provide not just the product but also the guidance to help you design, implement, and optimize your direct-to-chip cooling systems with confidence. Whether you’re planning a new deployment or looking to upgrade an existing setup, our team is here to support you at every step.

Contact Prostech today for a customized quotation and expert consultation tailored to your specific cooling requirements.