Powering EV/Hybrid Electric Vehicles (HEVs) Batteries with Busbars

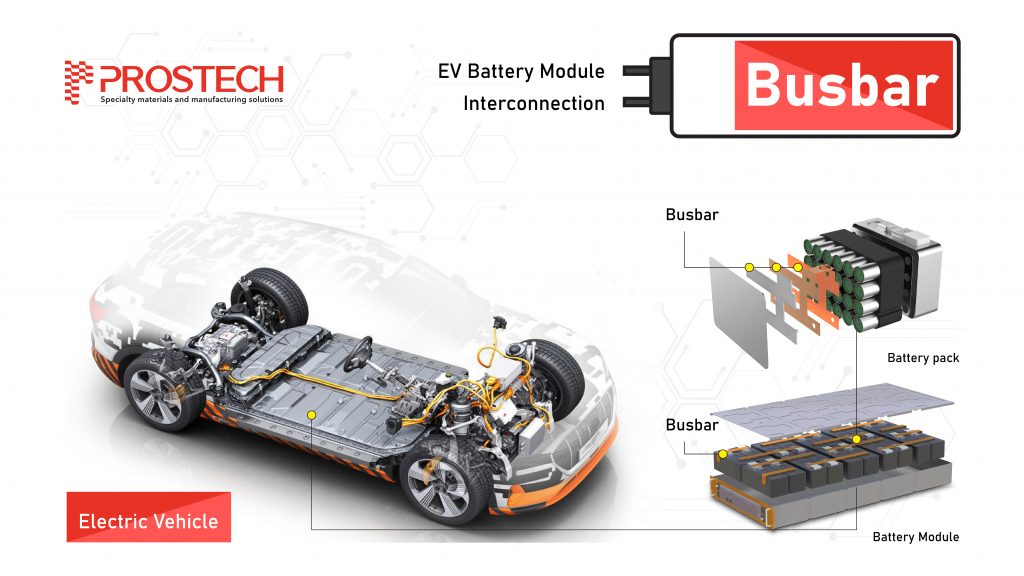

EVs and HEVs rely on robust electric motor drives, large-capacity battery packs, power inverters, and efficient distribution of power from the charging source to the battery and throughout the vehicle. Connection, which comprises a system of electrical conductors for collecting and distributing current, provides the means to efficiently distribute power to the vehicles’ various subsystems. A number of different types of connections including wires, cables, and busbars are commercially available, so specifying the best match for an EV/HEV application is a matter of understanding the various requirements and how different types of power connections can optimally address them.

The connections of battery cells as well as complete battery packs are essential parts of an EV/HEV battery design and provide thermal stability, electrical protection, and performance. Today, modern automotive battery packs typically consist of a very large number of battery cells, sometimes even thousands of cells. These cells must be assembled together with robust mechanical and electrical connections.

The conventional cell connections (welded wires, strips, or lugs) are susceptible to failure when the cells even slightly dislocate during operation, for example, due to the vibration of a moving vehicle. That is why new interconnection techniques using different busbar solutions have been introduced to overcome these challenges, especially for cylindrical cells.

Electrically, connections must handle high currents coming from the cells but also increase voltage levels as cells of the future will be up to 5.0V per cell. As a result, the impact on the clearance and creepage distance for the electrical insulation will be significant.

Mechanically, busbars for the battery pack of EVs/HEVs must be durable, capable of withstanding high levels of vibration while simultaneously providing rigidity to keep the integrity of the battery module assembly while also being flexible enough to cope with elastic, thermal, and G-forces.

The performance of the connections depends also upon the composite materials used to construct the busbars. They employ either copper or aluminum conductors in various thicknesses: standard thicknesses from 0.5 to 2.5 mm for copper and from 1.0 to 2.0 mm for aluminum for the battery cells. Busbars used to connect to the battery module itself (meaning the assembled array of battery cells) require higher thickness due to its higher current carrying requirements. Copper offers superior thermal characteristics vs aluminum, with the thermal conductivity of 401 W/mK for copper compared to 237 W/mK for aluminum, and thermal expansion of 16.5 ppm/K for copper compared to 23.1 ppm/K for aluminum.

Aluminum busbars are attractive for the battery cell connection because they provide reliable electrical performance while helping to save total battery pack weight since aluminum busbars are typically 50% lighter than copper busbars. For equivalent electrical/thermal performance, however, the cross-section of an aluminum busbar will be greater than that of a copper busbar with, for example, a 1-mm copper conductor replacing a 2-mm aluminum conductor. Copper busbars offer excellent solutions where space is tight, while aluminum busbars enable efficient energy distribution with weight savings compared to copper. Aluminum is also less costly than copper.

The next challenge is thermal management and a properly selected busbar can assist thermal management, especially for the cylindrical cell connections where the busbar may connect hundreds of cells to make a complete module. For the cylindrical cell, connections to the positive and negative electrodes can be made either from the top and bottom or only from the top. The disadvantage of top and bottom design is that it may prevent the efficient operation of either an air-based or a liquid coolant-based cooling system that is used to remove the heat generated by the cells during operation. That is why some carmakers select only the top connection of the battery cell, despite the fact the busbar is more complex. In this case, the busbar consists of two conductors (typically tin or nickel-plated to prevent oxidation) separated by an insulation film in-between. This film is also used on the outside to seal/laminate the busbar construction in a single structure.

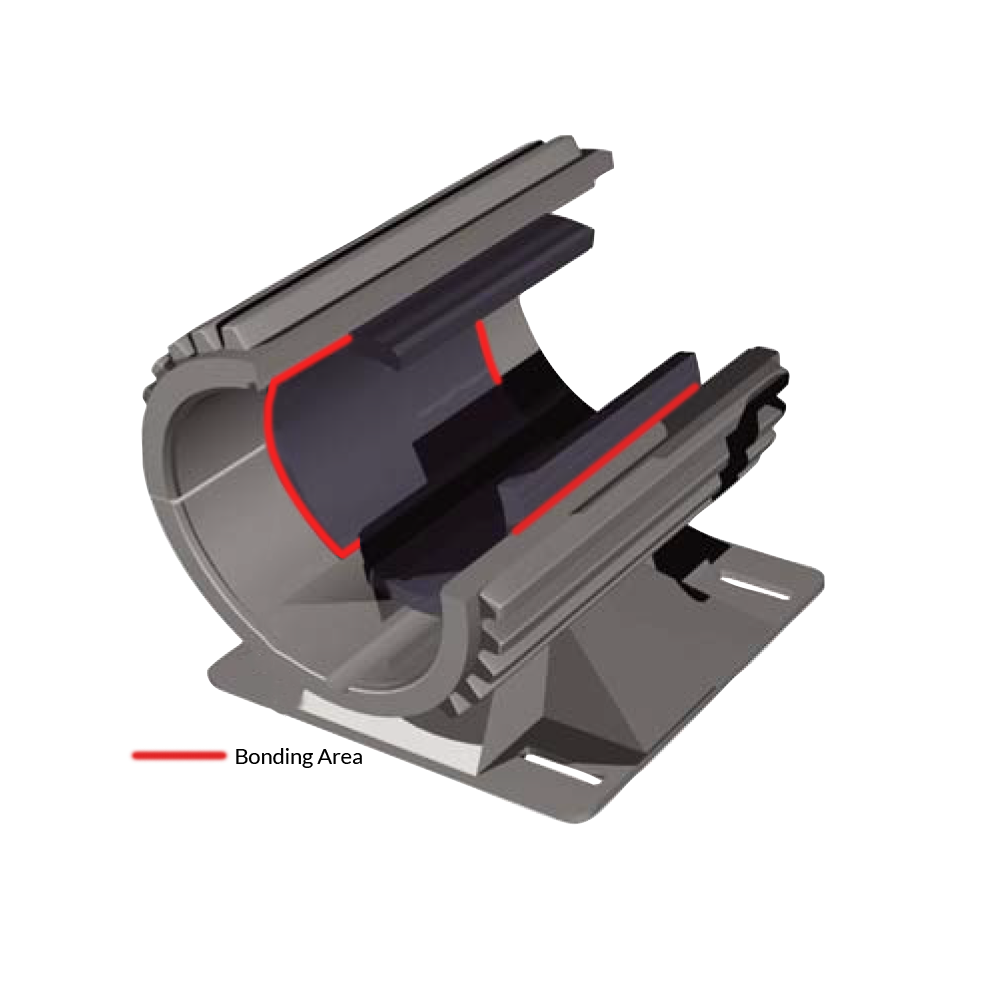

Another aspect is the connection between the cells and the busbar. It is important to minimize the contact resistance in order to reduce the electrical loss that generates heat at connection points along a busbar. In some cases, solder joints used to improve connection integrity can be associated with electrical loss and heat generation. To minimize contact resistance, it is recommended to laser weld groups of battery cells to a busbar for assembling the large, high-power battery packs for EVs/HEVs. Laser welded connections can also be made as part of an automated assembly process to minimize manufacturing costs in large-volume production.

Overall, busbar forms vary depending on the type of battery cells used in the battery pack. The busbar for the cylindrical cell is typically comprised of large flat separate conductors or conductors laminated into one structure without additional components mounted on them. While some complex busbars used for prismatic cells may have a hybrid format like the Hybrid busbar that not only provides power but can also transmit control signals from current or temperature sensors to the battery management systems (BMS) in the EV/HEV battery pack.

Prismatic cells can also use a very simple busbar design where the connection of each individual cell is performed mostly by mechanical joints, such as screw attached electrical lugs, inserted into an integrated housing solution. The busbar connects individual cells in a series, and it contains many small lugs and wires for the BMS.

The mechanical joining of pouch cells can be realized with or without a busbar. Some cell manufacturers are using complex busbars that combine lugs/small busbars and wiring for the BMS and housing. This solution requires very accurate positioning of busbars and cells that sometimes makes it difficult to obtain. That is why it is more common to eliminate the busbar and make a small module containing up to four cells where the tabs are welded together using ultrasonic or laser welding. Once welded, they are placed in a metal case to form a small module. Once modules are formed, they are assembled in the stack of the module to make a larger battery module. The connection of a stacked module is realized using a similar prismatic cell integrated housing solution.

Overall, we have to remember that the electrical cell connection is an essential element of the battery pack design and the selection of the busbar for the battery cell is not always as simple as one might think. If you have any design questions or require assistance for the optimization of your design using busbars for your application, PROSTECH experts are available to help. Please contact us if you have any questions.

[contact-form-7 id=”39095″ title=”Blog Contact Form”