Efficiency, cost-effectiveness, and performance are always key motivators for industry developments. However, apart from the usual manufacturing industry, the marine one, in particular, is faced with

♦ The impact of climate change

♦ Requiring resistance regarding harsh environment impacts

♦ Long-lasting and reliable manufacturing results

Likewise, developments have to improve on previous performance characteristics with more demanding requirements: such as speed, greater power and more aesthetic, to name just a few. As such, lightweight construction has seen tremendous growth and acceptance in recent years.

Just as in other segments of the transportation sector, there are many adhesives and sealant applications within the marine segment. The adhesive or sealant must be selected to match that specific application. So how do manufacturers know which materials meeting exactly their application’s requirements?

Pros Technology with a long and wide range of adhesives and sealants are always ready to meet your whatever requirements. The following would show you a glance at our solutions.

Structural 2K Polyurethane and Epoxy Adhesive for repairing applications

Hull-to-deck bonding with Araldite 2023 adhesive

Hull-to-deck bonding requiring high elongation and high E-modulus combined with high-bond-thickness to compensate for large production tolerances.

Thanks to its high gap-filling capabilities and elongation of >100%, ARALDITE 2023 adhesive compensates for production tolerances with no need for primer.

With enhanced long-distance pumpability, the bonding process is fast and efficient. The result is a durable bond that eliminates future maintenance and refitting needs.

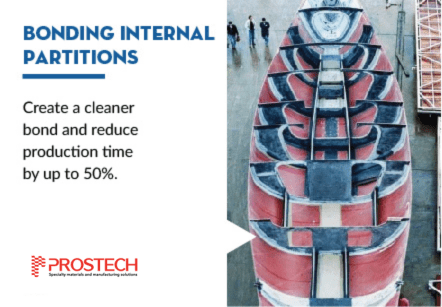

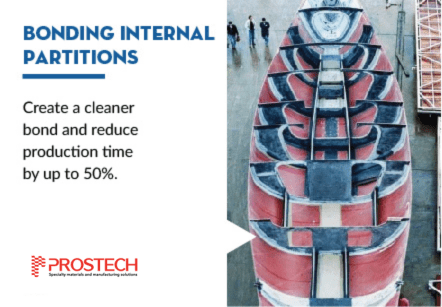

Bonding internal partitions with Araldite 2023 adhesive – Replacing and sealing internal lamination.

ARALDITE® 2023-30 adhesive is 100% non-sagging, meaning you can easily apply it to complex surfaces, both vertical and overhead. With no need to apply primer, the panel is pre-positioned and the adhesive is injected, acting as structural load carrier and sealant at the same time.

The combination of primeless application and a one-step bonding process can speed up the process by up to 50% and result in a cleaner assembly compared to the traditional lamination process.

Bonding and repair at sea with Araldite 2051 adhesive

It is always challenging to repair and finish small to medium-sized components after a ship has left the controlled conditions of the shipyard and is exposed to a wet, cold environment.

Packed in handy and safe cartridges, ARALDITE 2051 adhesive is a valuable tool to keep onboard. This adhesive will help you speed up repairs and get back to operations quickly, reducing your downtime by up to 50%.

With ARALDITE 2051 adhesive, you can bond any kind of material outdoors – and even underwater. This non-sagging adhesive is easily applied vertically and overhead for both small fixes and major repairs.

Thread all locks of your ships with our Anaerobic Adhesives which are generally selected for thread-locking or thread sealing applications.

♦ Available in a range of viscosities to suit component size, diameter, and fit

♦ Prevent corrosion, metal fretting, vibration loosening.

♦ Machining tolerances can be relaxed (no more interference or shrink fits)

♦ Help lubricate parts making the assembly process much easier

♦ Gasketmakers are ideal for making a whole variety of different shaped gaskets

♦ Excellent resistance to water, oil, petrol and other chemicals

♦ High-temperature resistant products also available

Cyanoacrylate Instant Adhesive or called Super Glue for general purpose instant bonding applications in:

♦ Repairing interior trim

♦ Ruber mat edges to prevent trip hazards